Preparation method for essential oil of fresh wintersweet flowers

A technology of sweet plum flowers and essential oils, applied in the directions of essential oils/spices, fat generation, etc., can solve the problems of heat-sensitive components destroying the safety of solvent residues, etc., and achieve the effect of realistic aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

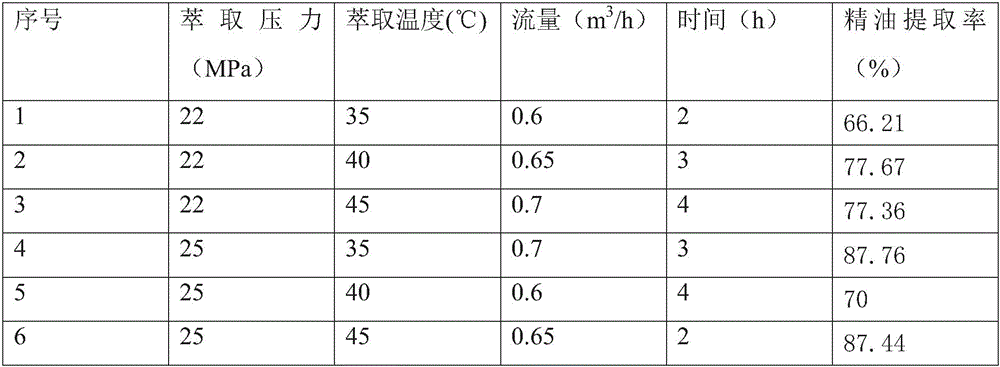

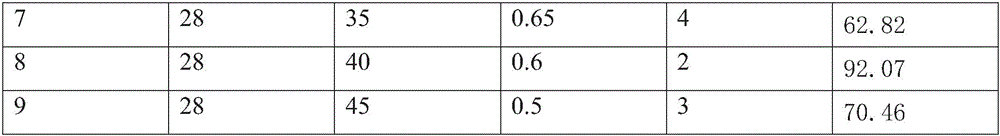

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with specific embodiments:

[0018] The present invention proposes a kind of preparation method of wintersweet flower essential oil, comprises the steps:

[0019] (1) Pretreatment: After the wintersweet flowers are picked, they are selected and removed, and stored in a freezer at a low temperature of -20°C to -15°C;

[0020] (2) obtain fresh wintersweet flower extract through extraction and separation;

[0021] (3) Molecular distillation: send the wintersweet flower extract through oil-water separation into molecular distillation equipment and carry out molecular distillation, the column temperature of the distillation column is 100-110 ℃, and the distillation pressure is controlled at 1-3Pa to obtain the wintersweet flower essential oil.

[0022] In the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com