Methods of Improving Plasticity of 5052 Aluminum Alloy as Cold Rolled

An aluminum alloy and plasticity technology, which is applied in the field of improving the plasticity of 5052 aluminum alloy, can solve the problems of poor plasticity in cold rolling state of 5052 aluminum alloy, and achieve the effect of improving elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

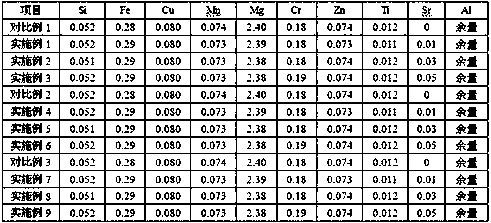

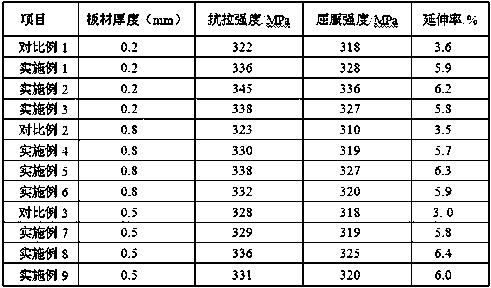

Embodiment 1

[0014] The steps of the method for improving the plasticity of 5052 aluminum alloy in the cold-rolled state in this embodiment are as follows: add 0.01% Sr to the 5052 aluminum alloy slab, and prepare a recrystallized slab through hot rolling and heat treatment processes. The thickness of the slab is 10 mm, and the The prepared slab is cold-rolled in two steps. The first step is cold-rolled through three rolling passes. The surface temperature of the slab entering the rolling mill is controlled at 63°C, and the plate is rolled to a thickness of 2.5mm. After cold rolling, an intermediate annealing is carried out, the intermediate annealing temperature is 350°C, and the holding time is 1.5h; the second step of cold rolling is through three rolling passes, and the surface temperature of the slab entering the rolling mill is controlled at 66°C, and the plate is rolled to 0.2mm thick.

Embodiment 2

[0016] In this example, 0.03% Sr is added to the 5052 aluminum alloy slab. The surface temperature of the slab when it enters the rolling mill is 61°C, and the surface temperature of the plate before the second cold rolling is 65°C. Other characteristics are the same as in Example 1.

Embodiment 3

[0018] In this embodiment, 0.05% Sr is added to the 5052 aluminum alloy slab, and the surface temperature of the slab entering the rolling mill is 62° C., and other characteristics are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com