A kind of shoe upper fabric, shoe upper and shoe upper manufacturing method

A manufacturing method and a technology for uppers, which are applied in the field of uppers, uppers, and upper fabrics, can solve the problems of reduced flexibility of upper fabrics, affecting the flexibility of upper fabrics, and reduced thickness of upper fabrics. Achieve the effects of preventing color shift, high mechanical strength, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Please refer to Figure 1 to Figure 2 , Embodiment 1 of the present invention is:

[0085] A shoe upper fabric 1, comprising an insulating cloth layer and a water-based slurry coating, the weight ratio of each component of the water-based slurry coating is:

[0086] Starch 1%~3%;

[0087] Fumed silica 1% to 2%;

[0088] Water 95% to 98%.

[0089] A vamp, comprising the above-mentioned vamp fabric 1 and a patterned layer 2, the patterned layer 2 is made by inkjet printing of a digital printing machine, and the ink used on the digital printing machine is disperse dye ink.

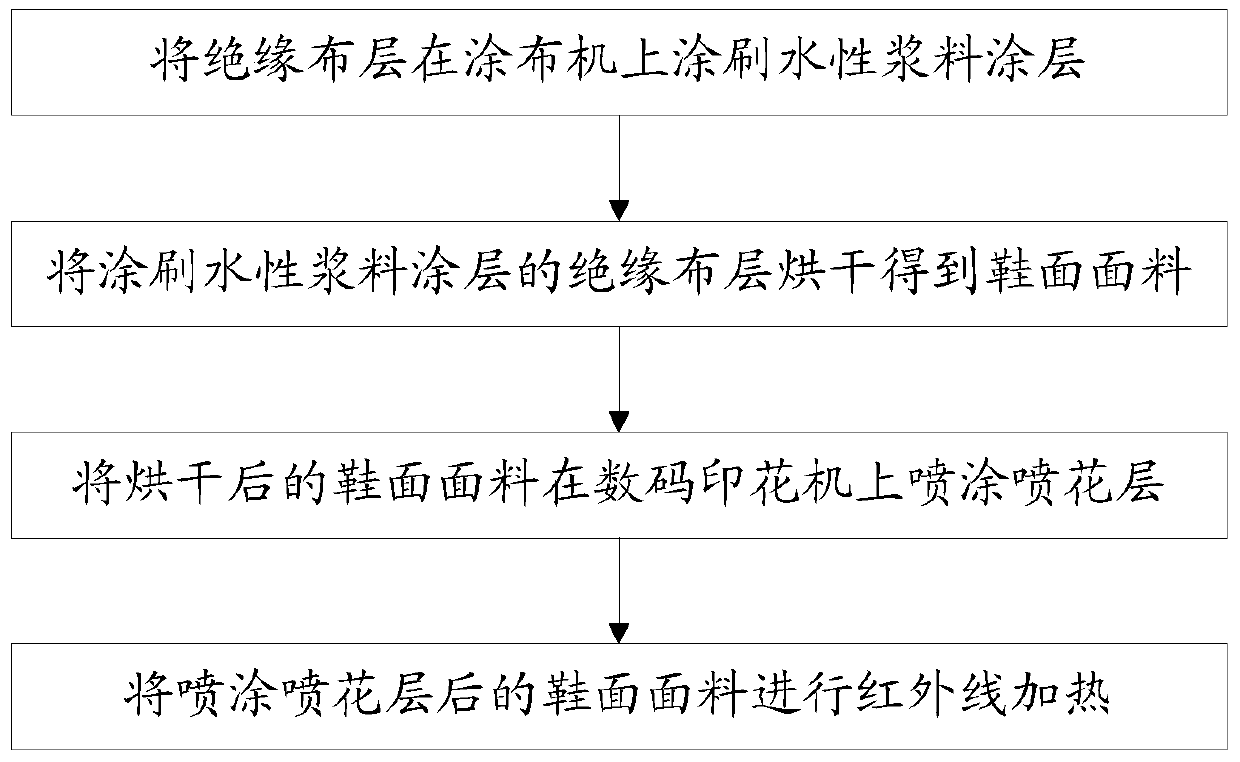

[0090] A method for making a shoe upper,

[0091] S1 Apply the above-mentioned water-based slurry coating on the insulating cloth layer on the coating machine, wherein the temperature of the water-based slurry coating is 53°C to 60°C;

[0092] S2 drying the insulating cloth layer coated with water-based slurry coating to obtain shoe upper fabric 1, the drying temperature is 110°C-120°C, and air co...

Embodiment 2

[0096] Please refer to Figure 1 to Figure 2 , the second embodiment of the present invention is:

[0097] A shoe upper fabric 1, comprising an insulating cloth layer and a water-based slurry coating, the weight ratio of each component of the water-based slurry coating is:

[0098] Modified acrylic acid polymer 3% to 8%;

[0099] Fumed silica 1% to 2%;

[0100] Water 90%~96%;

[0101] Wherein, the weight ratio of each component of the modified acrylic acid polymer is:

[0102] Ethylene-ethyl acrylate copolymer 20%~40%;

[0103] Acrylic acid-hydroxypropyl acrylate copolymer 60% to 80%.

[0104] A shoe upper, comprising the above-mentioned shoe upper fabric 1 and a sprayed pattern layer 2, the sprayed pattern layer 2 is made by inkjet printing of a digital printing machine, and the ink used on the digital printing machine is a disperse dye ink.

[0105] A method for making a shoe upper,

[0106] S1 paints the above-mentioned water-based slurry coating on the insulating cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com