Integrated casing pipe drilling machine

An integrated, bushing technology, applied in earth movers/shovels, construction, etc., can solve problems such as difficult collaborative operations, low automation, and lack of moving structures, so as to reduce equipment investment and operators Small quantity, good coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] Preferred embodiment:

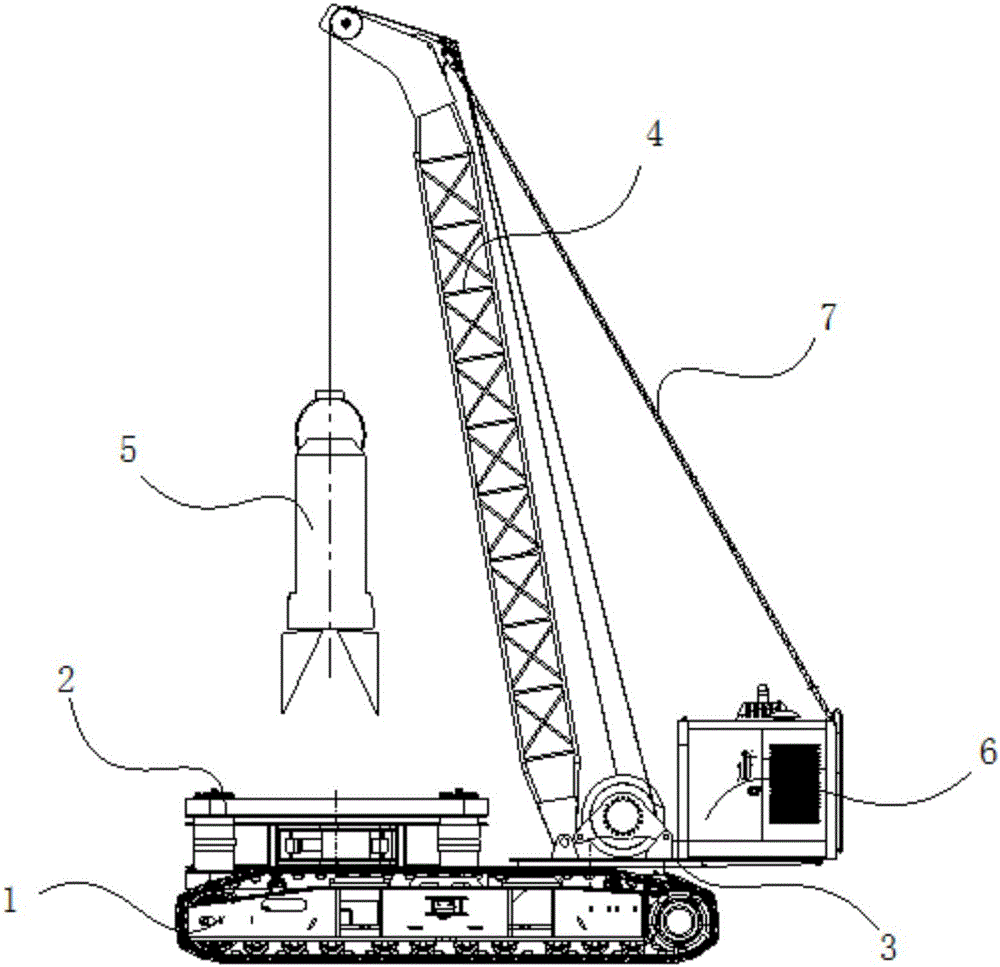

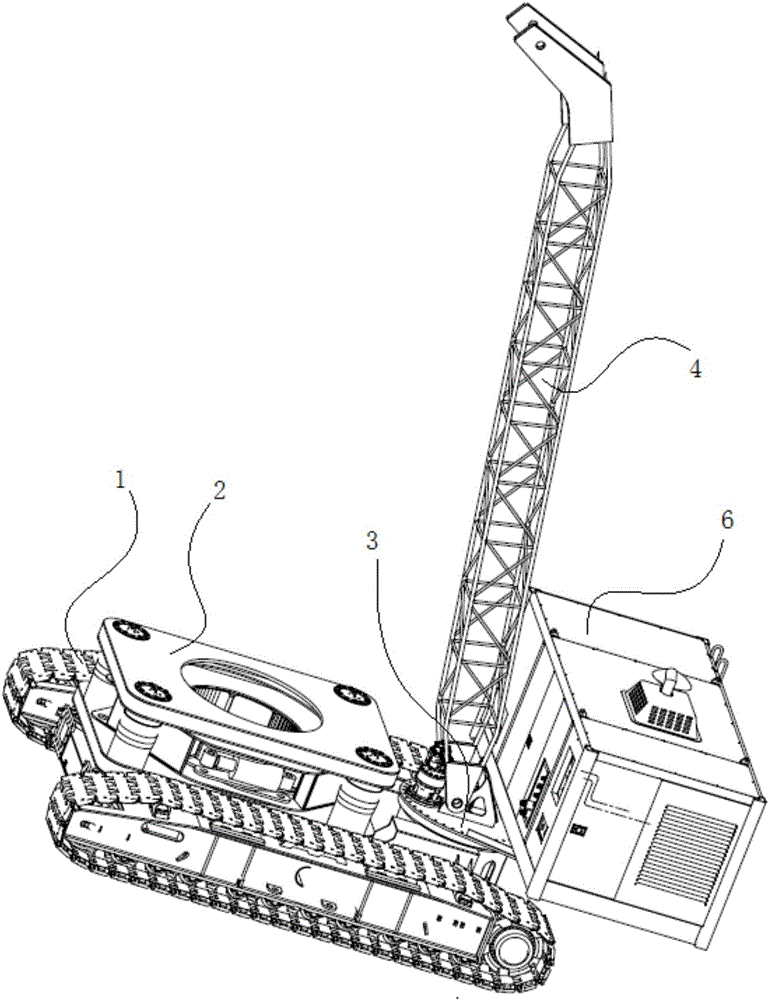

[0024] The preferred embodiment discloses an integrated casing drilling machine. Such as figure 1 with figure 2 As shown, the integrated casing drilling rig includes a traveling device 1, on which a tube rubbing device 2 and a rotary platform 3 are respectively arranged, and the rotary platform 3 is provided with a boom 4 and a hoisting system, and the hoisting system The hoisting rope spans the end of the boom 4, and the free end of the hoisting rope is connected to the punching grab 5; the rotary platform 3 can drive the punching grab 5 to rotate in the plane through the boom 4 to grab the punching grab The materials (soil, rocks, etc.) are sent to the designated location.

[0025] The one-piece casing drilling rig integrates the traveling device 1, the rubbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com