Radiating device of Stirling engine

A technology of Stirling engine and heat dissipation device, which is applied in hot gas variable capacity engine devices, engine components, machines/engines, etc., can solve problems such as serious energy loss, and achieve energy recovery, easy portability, and reliable and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

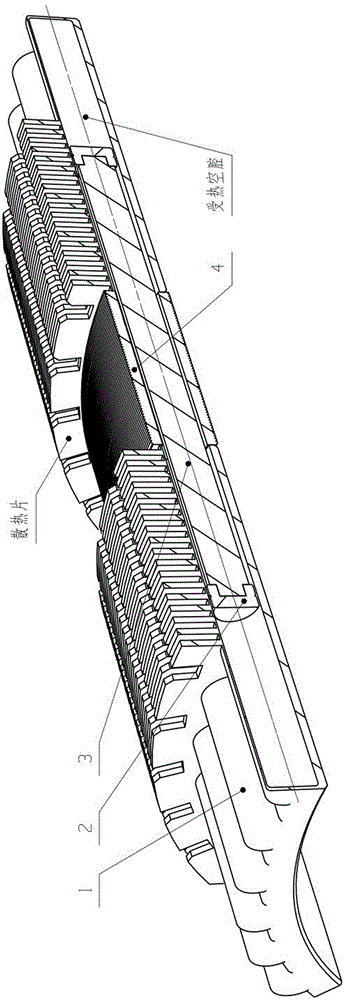

[0014] Such as figure 1 As shown, the heat dissipation device of the Stirling engine is composed of a cylinder block 1, a heat insulating ring 2, a magnetic bar 3 and a radiator 4, wherein: the cylinder block 1 is a symmetrically arranged hot cavity and a cold cavity, and are respectively connected with The magnetic bar 3 and the radiator 4 are connected, and the hot chamber and the cold chamber are connected through rods; the cylinder block 1 is filled with hydrogen or helium gas, and after cooling, compression, heat absorption, and expansion, a cycle of output power is formed, and The heat ring 2 is arranged symmetrically in the cylinder body 1 on both sides; the magnetic rod 3 is arranged in the middle of the two heat insulation rings 2; by heating the hot chambers on both sides of the symmetry, the pressure of the hot chamber and the cold chamber are different, Push the two insulation rings 2 to make a linear reciprocating motion under the guidance of the cylinder wall, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com