Control system adopting opposite rotation for vertical axis type wind driven generator

A wind turbine and control system technology, applied in the control of wind turbines, wind turbines, engines, etc., can solve problems such as inability to provide electric energy, affect power generation efficiency, and difficulty in speed regulation, and achieve reduced size and radius of gyration, and extended Effective life and reduced mechanical load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A counter-rotating vertical-axis wind power generator control system provided by the present invention will be explained in detail below in conjunction with the accompanying drawings.

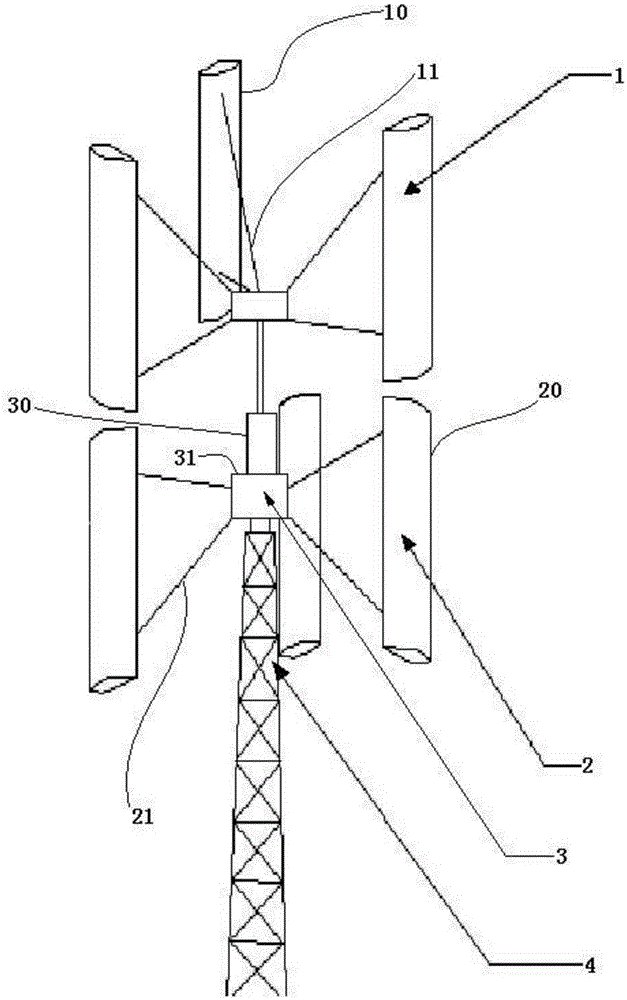

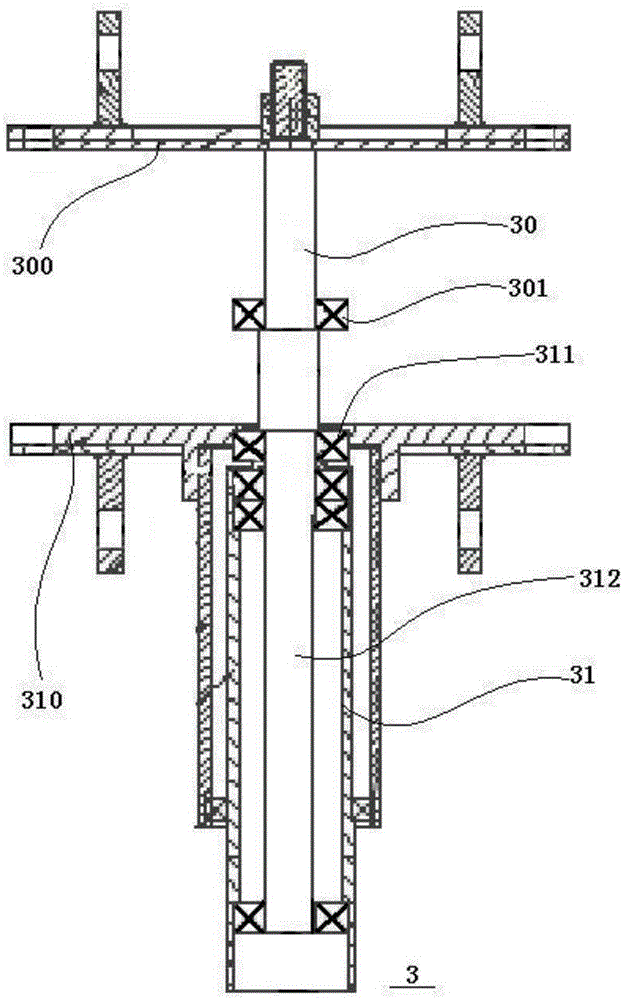

[0024] refer to figure 1 , a facing vertical axis wind power machine includes a permanent magnet machine 3 including a stator 30 and an outer rotor 31 . The stator 30 is cylindrical, while the outer rotor 31 is cylindrical, and the inner radius of the outer rotor 31 is larger than the radius of the stator 30, so that the stator 30 can rotate relatively freely in the inner hollow of the outer rotor 31 , both the stator 30 and the outer rotor 31 can rotate, and their names are those of traditional technology, and their functions cannot be limited.

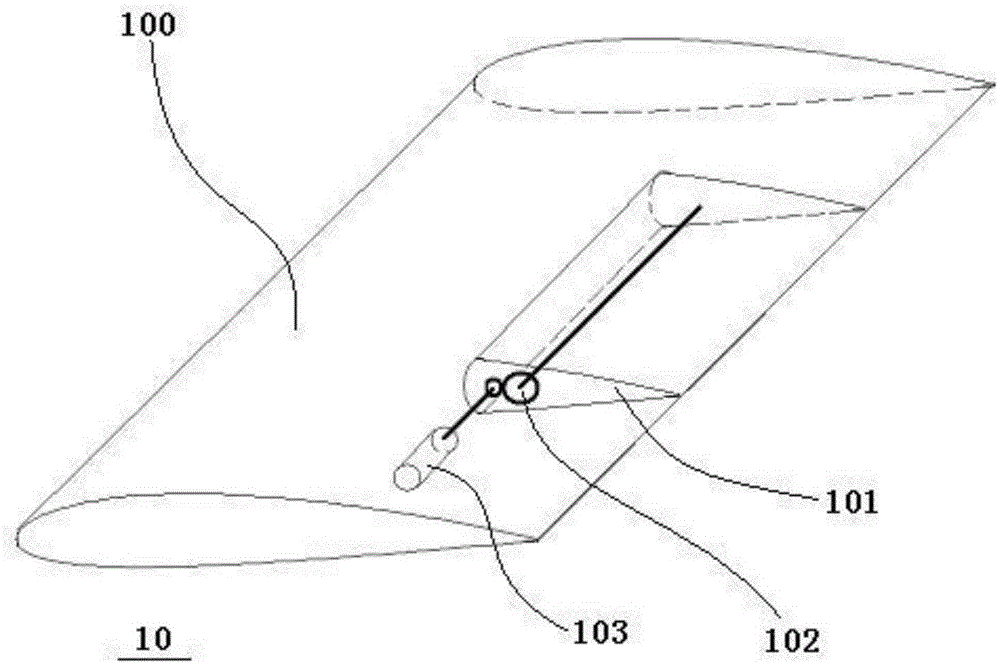

[0025] This counter-rotating vertical axis wind power generator control system also includes a stator blade set 1 and an outer rotor blade set 2 . The stator blade set 1 is installed on the stator 30 and can drive the stator 30 to rotate in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com