Large-proportion coal slime blending combustion device and method for thermal power generation

A large-scale, slime technology, applied in the field of thermal power generation devices, can solve the problems of inability to achieve deflagration, slime pipeline vibration, and high pipe racks, and achieve the effects of easy popularization and use, vibration prevention, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

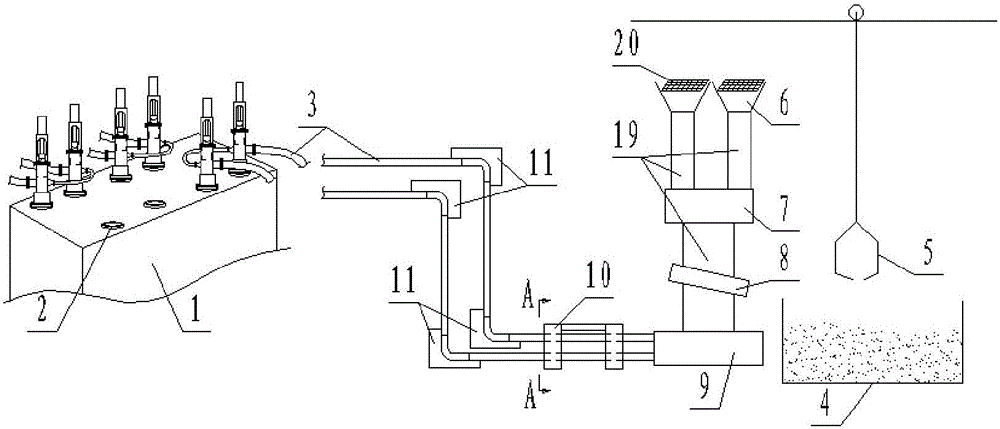

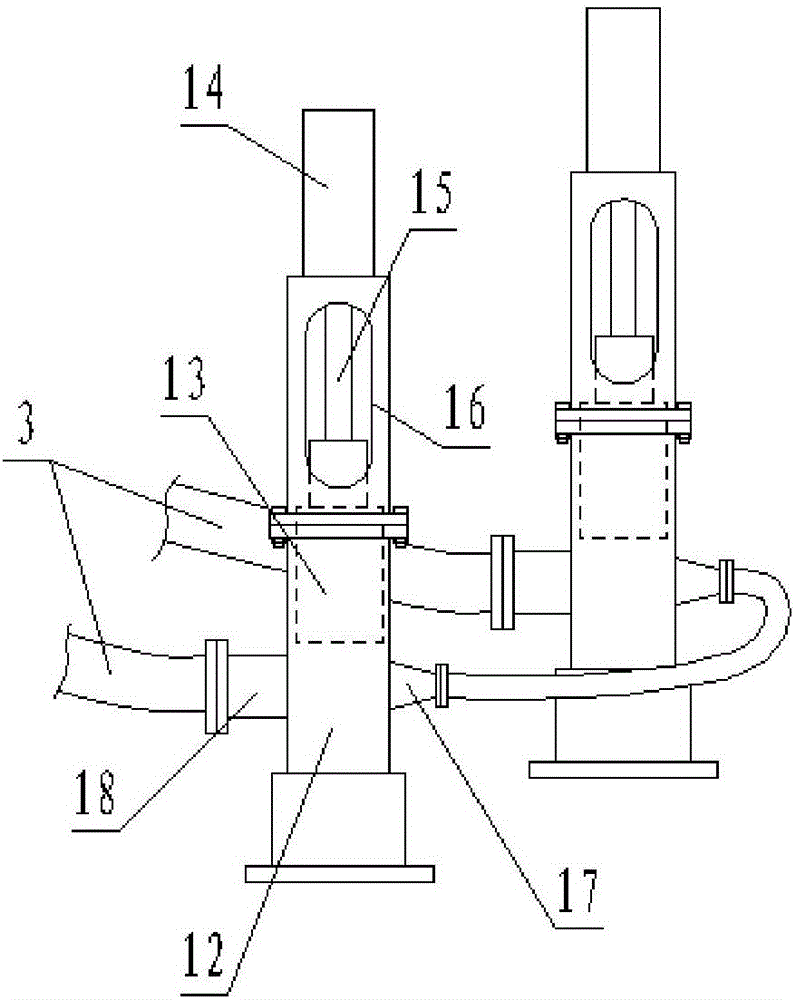

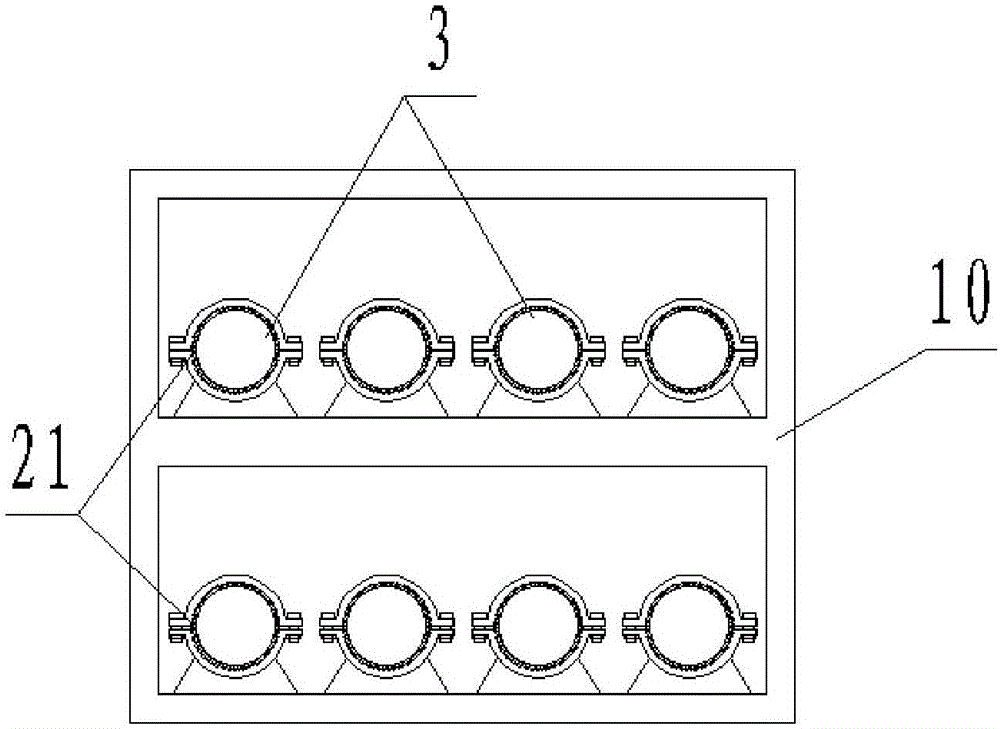

[0027] A device for blending coal slime in a large proportion in thermal power generation, comprising a furnace body 1 and a slime pool 4, a hopper 6 is arranged on one side of the slime pool 4, an agitator 7 is arranged below the hopper 6, and the agitator 7 The plunger pump 9 is arranged below the hopper, the hopper 6 and the agitator 7 and between the agitator 7 and the plunger pump 9 are respectively connected by a vertical drop pipe 19, and a coal slime grate 20 is arranged at the mouth of the hopper 6 ,Such as Figure 4 Shown, coal slime grate 20 adopts the grid structure that steel bar is welded. On the falling pipe 19 between the agitator 7 and the plunger pump 9, a vibrating screen 8 is arranged, and a plurality of coal slime inlets 2 are arranged on the top of the body of heater 1 to communicate with the hearth of the body of heater 1, and each coal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com