A method for detecting channel abnormalities of vibration monitoring and protection devices for rotating equipment

A technology of vibration monitoring and protection devices, which is applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems such as simple functions, abnormal vibration signal channels, and incorrect actions of vibration monitoring and protection devices, so as to improve reliability , Improve the effect of self-inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Embodiment: The present invention designs a correlation-based detection method for the channel abnormality of the vibration monitoring protection device of the rotating equipment. The specific implementation of this method will be described below in combination with the specific situation of a 300MW hydroelectric unit in a certain power plant, and the channel abnormality detection of the above X-direction measuring point as an example.

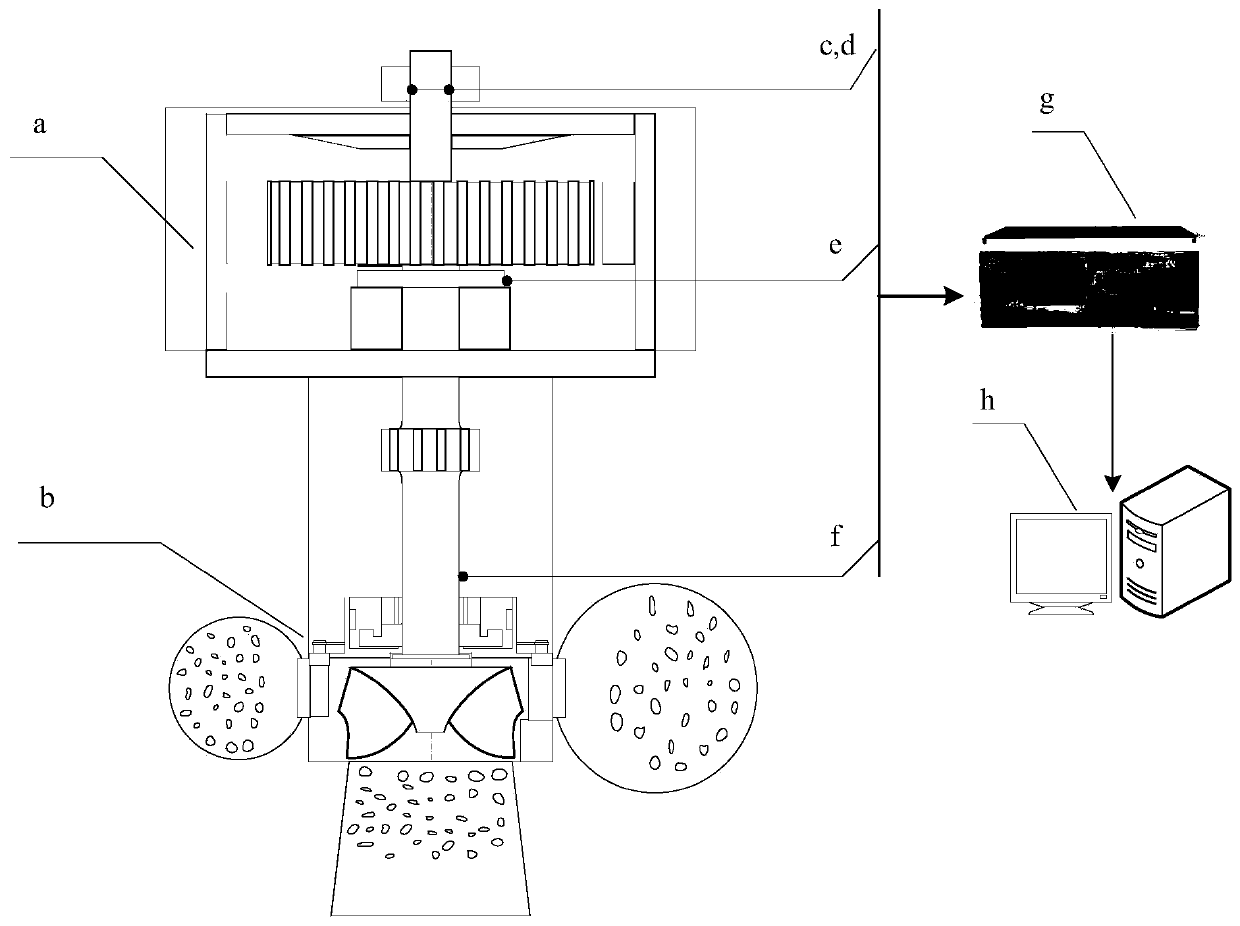

[0025] The main wiring diagram and the wiring of the rotating equipment vibration monitoring protection device and the background analysis system are attached figure 1 shown.

[0026] The design water head of the turbine is 51m, and the design flow is 114m 3 / s, rated output 306MW, runner installation elevation 205m, rated speed 500rpm, number of runner blades 7;

[0027] The rated capacity of the generator is 300MW, the rated power factor is 0.9, and the rated voltage is 20kV.

[0028] Set a set of swing signal measuring points in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com