Turbine disc-based low-cycle fatigue crack propagation life prediction method

A crack growth life, low cycle fatigue technology, applied in measuring devices, elasticity testing, machine/structural component testing, etc., can solve problems such as the inability to consider the effect of the crack growth rate of turbine disk grain size dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method for predicting the life of a turbine disk based on the average grain size of low-cycle fatigue crack growth will be further described below in conjunction with the accompanying drawings.

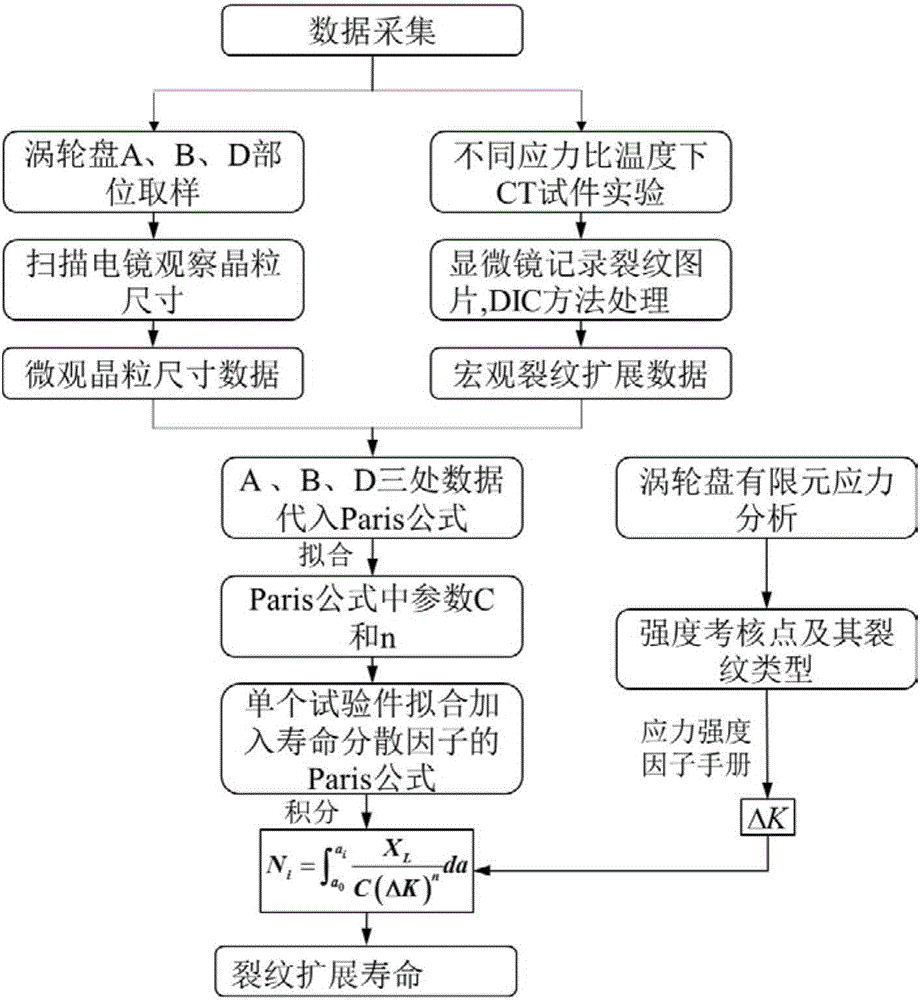

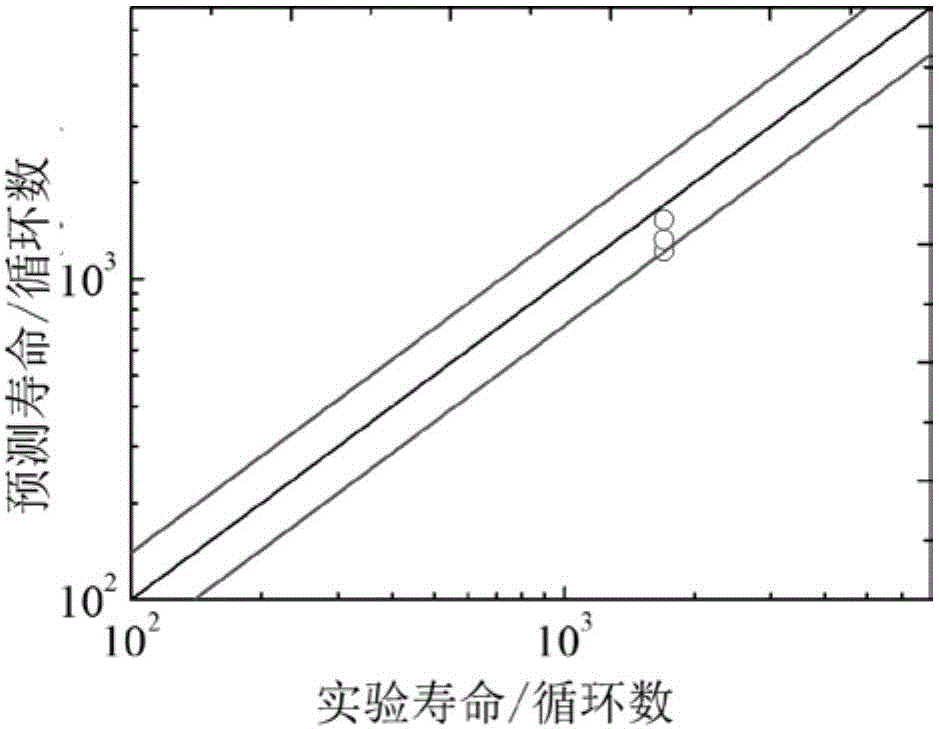

[0022] From the perspective of grain size, strengthening phase / secondary phase distribution and other microstructures, combined with the observation of macroscopic crack closure, the influence of grain size on crack propagation behavior is quantified by introducing the life dispersion factor. The low-cycle crack growth research method of the size, its flow chart see figure 1 .

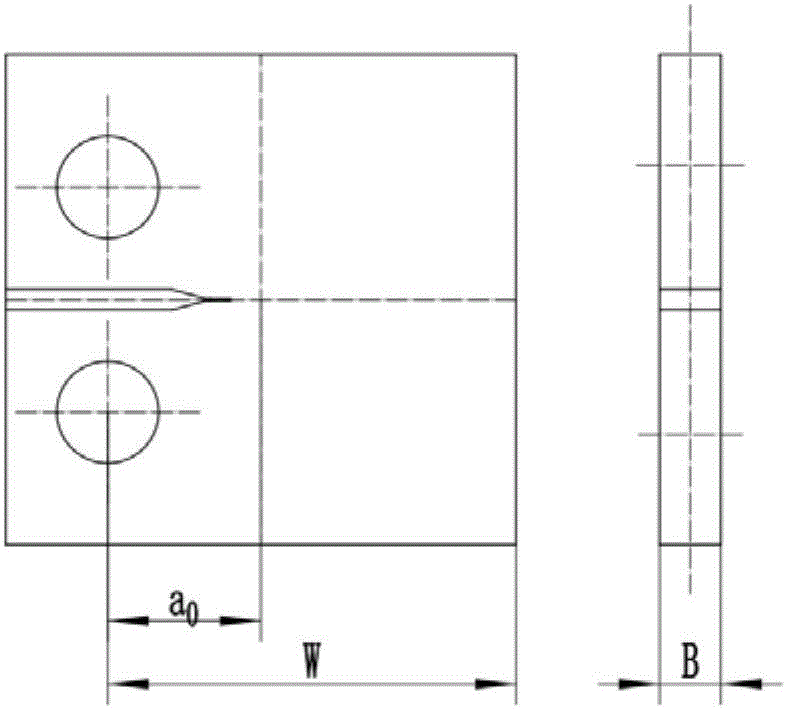

[0023] (1) Microscopic grain size data collection: Multiple samples were taken at three typical positions of the turbine disk edge A, disk center B and installation edge D, and the sampling frequency was 5-10 times. The microstructure characteristics were observed by scanning electron microscope. Including the distribution of grains, secondary phase / strengthening phase, measure and record the grain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com