Online detection system for density distribution of coal material

A technology of density distribution and detection system, applied in measurement devices, specific gravity measurement, analysis of materials, etc., can solve the problems of only analyzing the density distribution of surface layer coal, and it is difficult for machine vision equipment to identify coal particles, so as to improve on-site adaptability and The effect of detection accuracy, energy saving and cleanliness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

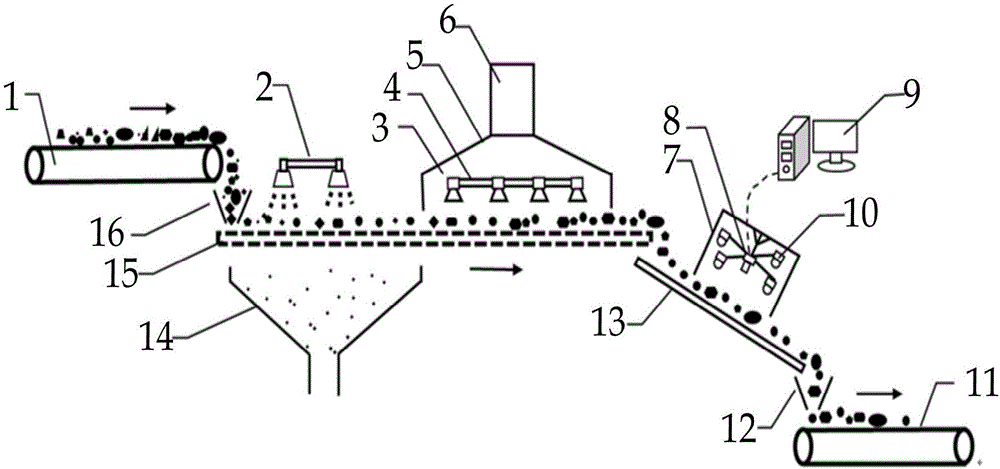

[0032] The embodiment of the present invention provides an online detection system for coal density distribution, which solves the technical problems that machine vision equipment is difficult to identify coal particles in the prior art, and machine vision technology can only analyze the surface coal density distribution, so that the coal particles to be detected The surface of the coal material is clean, dry and distributed in a single layer, which greatly improves the on-site adaptability and detection accuracy of the coal material density distribution online detection device, and provides accurate coal material image information for the upper computer, which is convenient for analyzing the coal material through machine vision technology density distribution.

[0033] see figure 1 , the embodiment of the present invention provides an online detection system for coal density distribution, including:

[0034] Vibrating screen 15 is used to obtain coal material and disperse th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com