Ultrasonic guided wave online detection device of high-temperature pipeline based on T-shaped waveguide structure

An ultrasonic guided wave and waveguide structure technology, which is used in measurement devices, solids analysis using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, etc. , affecting economic benefits and other issues, to achieve the effect of simple installation, easy installation and disassembly, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to the accompanying drawings, but the high-temperature pipeline ultrasonic guided wave online detection device of the present invention is not limited to the embodiments.

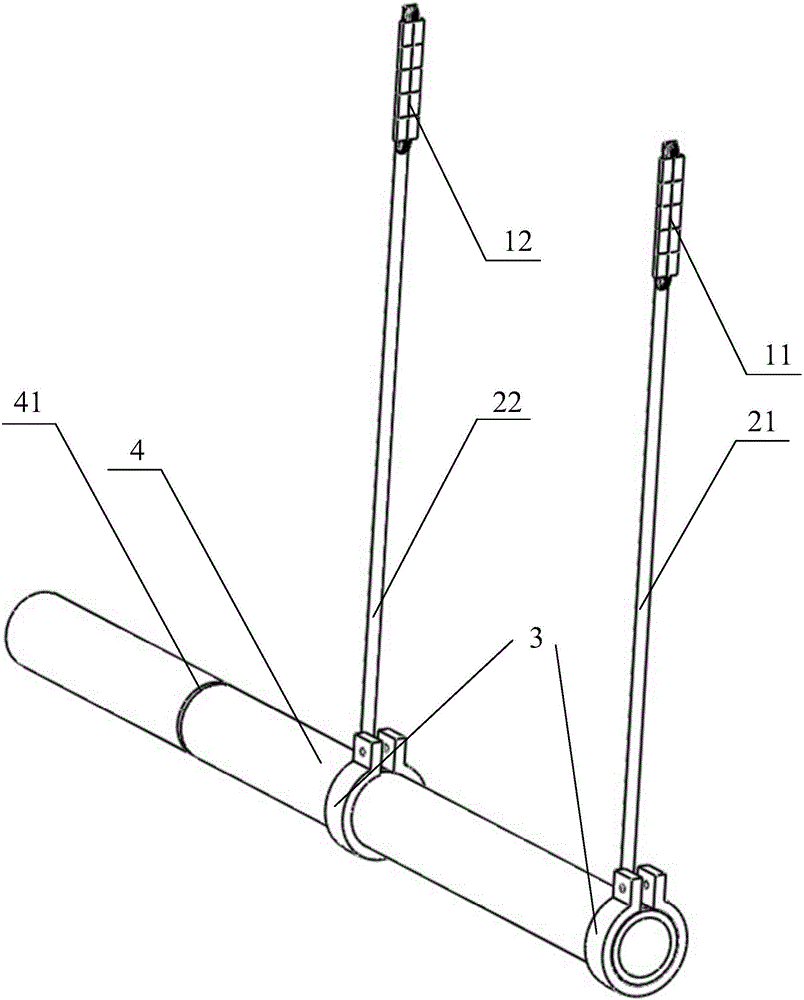

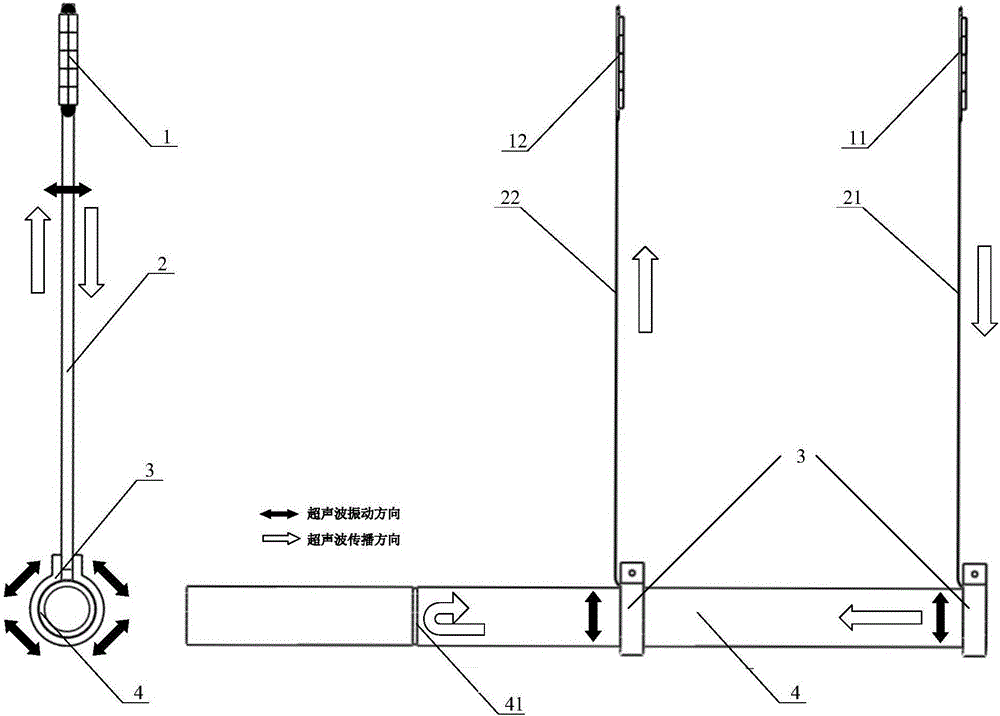

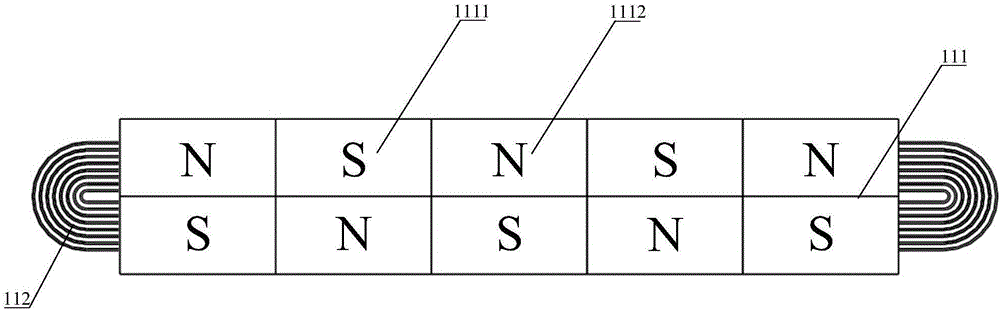

[0026] Such as figure 1 with figure 2 As shown, a high-temperature pipeline ultrasonic guided wave online detection device based on a T-shaped waveguide structure according to the present invention includes an ultrasonic guided wave probe 1, a T-shaped waveguide 2, a waveguide connector 3, and a pipeline 4 to be tested. The ultrasonic guided wave probe 1 includes a transmitting probe 11 and a receiving probe 12, which excite and receive ultrasonic waves by means of separate transmission and reception; the T-shaped waveguide 2 uses two identical T-shaped thin steel plates as the transmitting waveguide 21 and the receiving waveguide 22, and the transmitting waveguide 21 The T-shaped end of the receiving waveguide 22 and the T-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com