Method and device for non-destructive testing of curing degree of pot insulators for high voltage switchgear

A basin-type insulator and high-voltage switch technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze the thermal development of solids, instruments, materials, etc., can solve the problem of inapplicable performance testing, and it is difficult to fully reflect the curing degree of large-scale basin-type insulators, etc. problem, to achieve the effect of improving the quality of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] Example of non-destructive testing method for curing degree of pot insulators for high voltage switchgear:

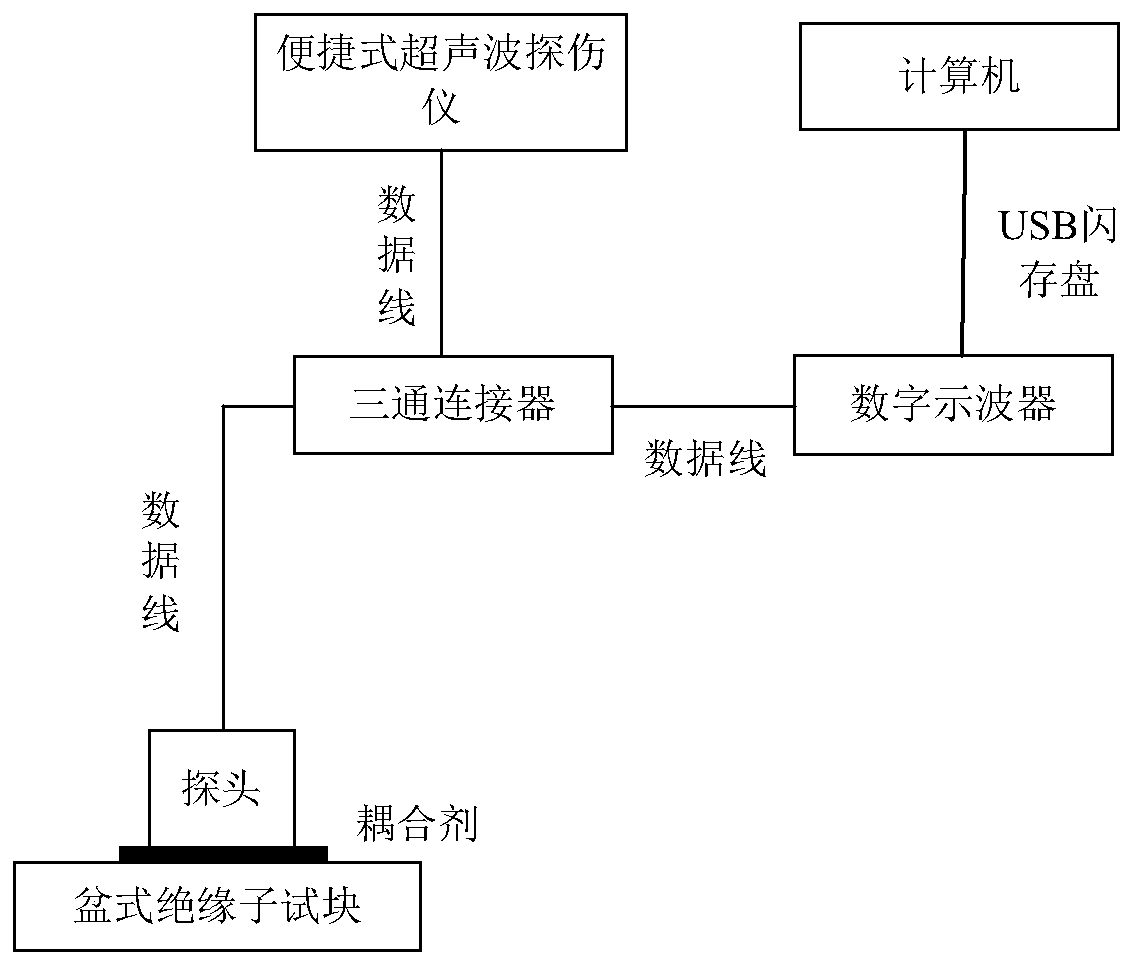

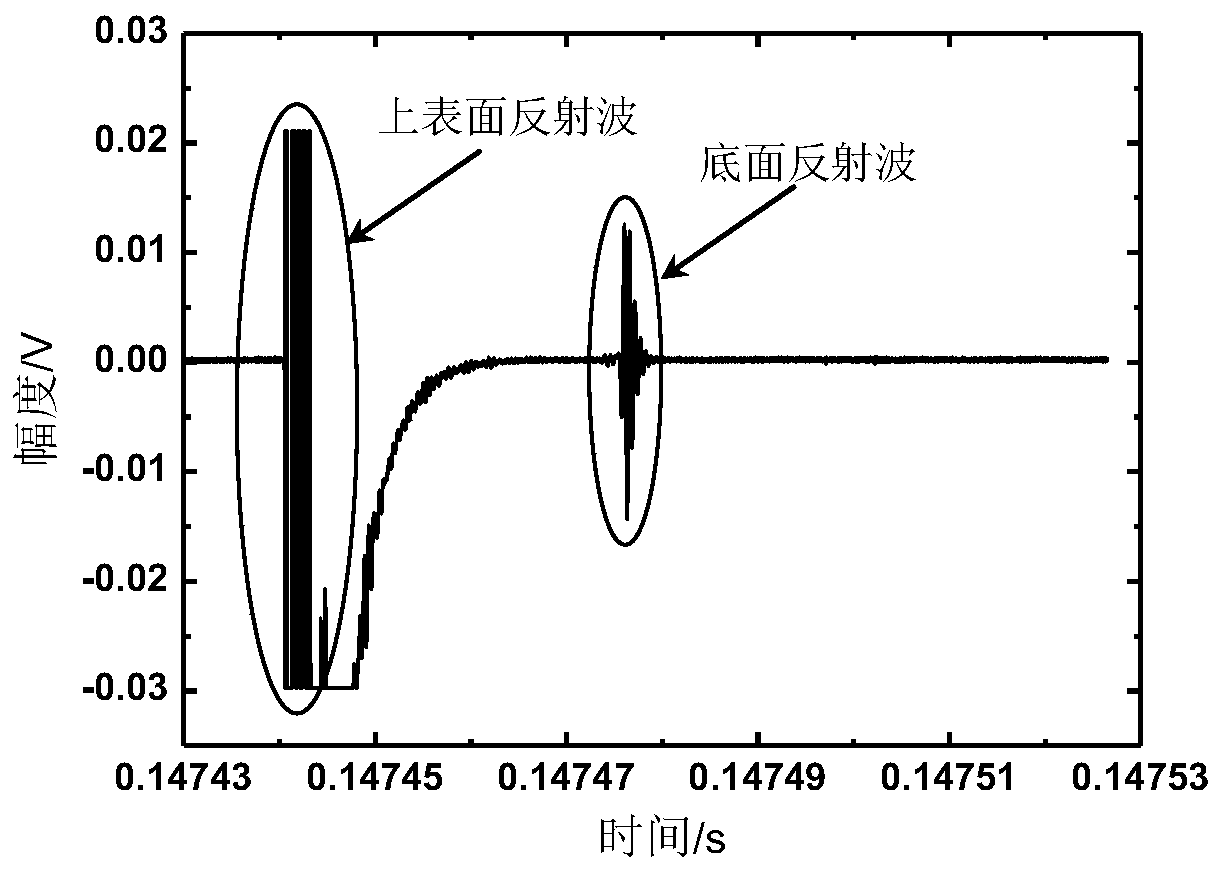

[0044] First, obtain the relational library of the corresponding relationship between the degree of solidification of the insulator and the power spectrum of the ultrasonic reflection signal on the bottom surface of the insulator, which mainly includes the following steps:

[0045] (1) Obtain test samples of pot insulators with uneven curing degree.

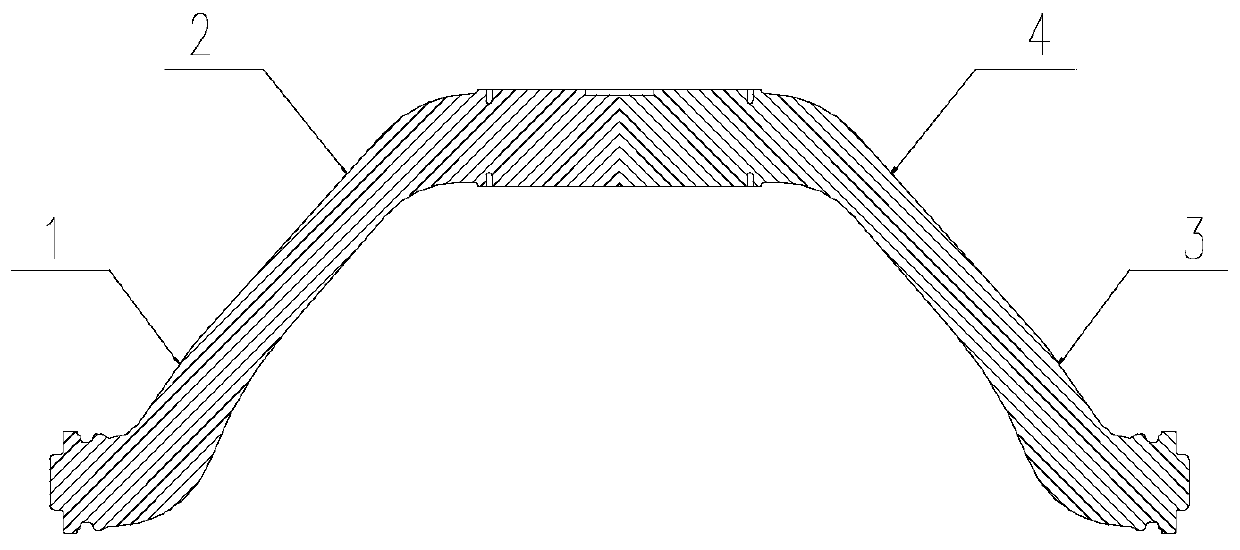

[0046] In order to obtain different curing degree distributions on the same pot insulator test sample, the 1100kV pot insulator is poured vertically, and the front view of the pot insulator test sample obtained is as follows figure 1 shown. exist figure 1 Among the positions 1-4 of the middle pot insulator test sample, position 1 is the first curing area, the subsequent curing areas are position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com