Motion track planning method and system for carrying robot

A technology for robot movement and handling robots, used in control/regulation systems, instruments, non-electric variable control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

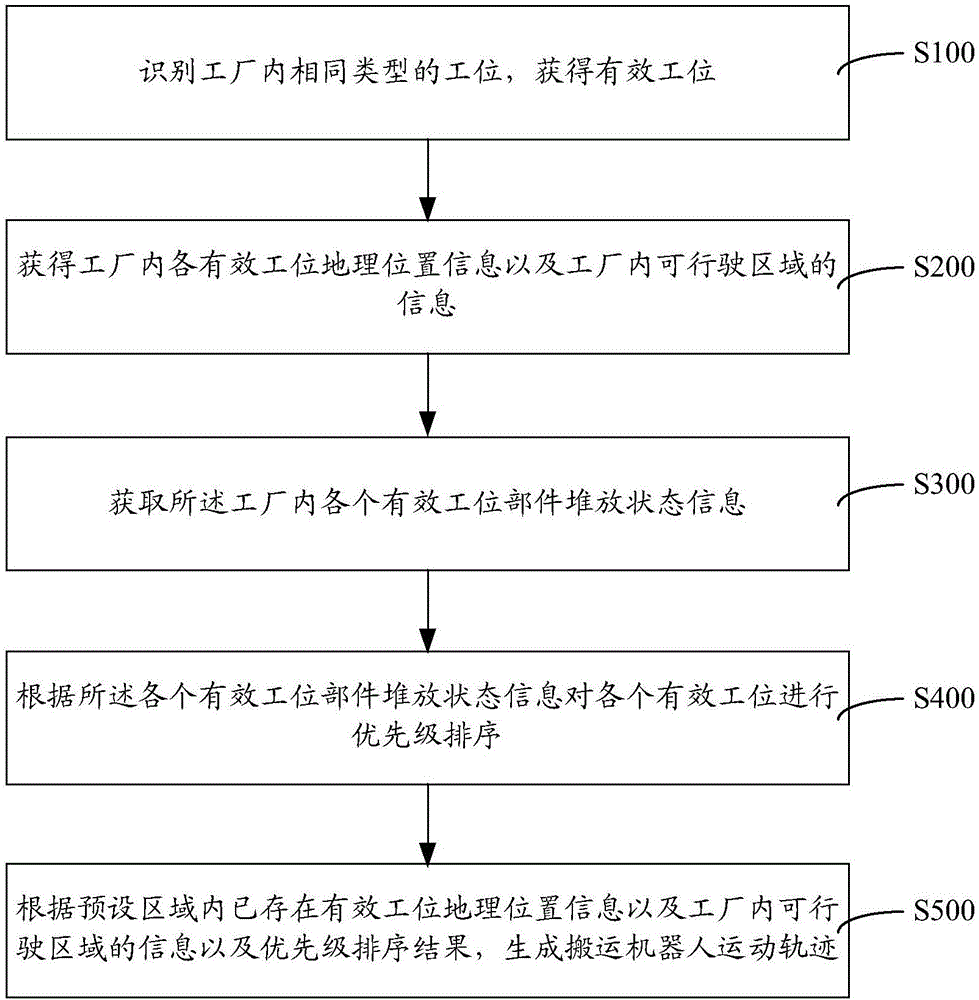

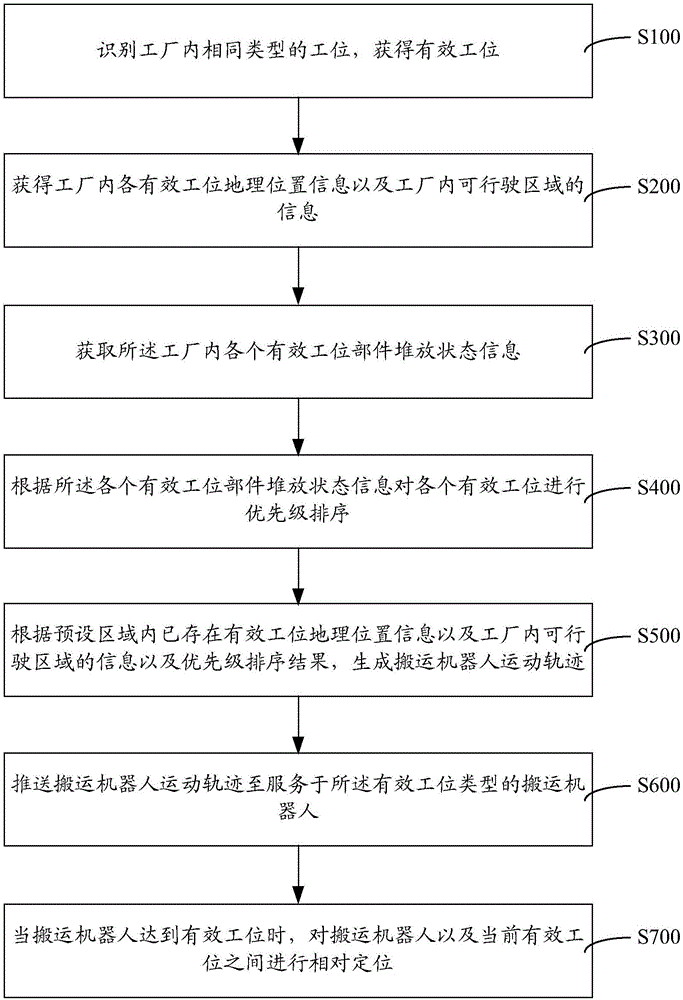

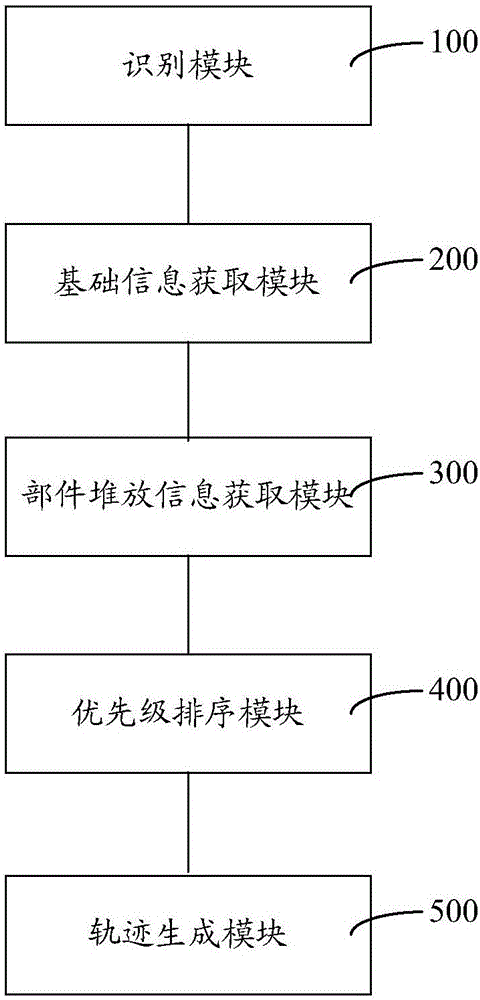

[0023] Such as figure 1 As shown, a moving robot trajectory planning method, including steps:

[0024] S100: identifying the same type of workstations in the factory, and obtaining valid workstations.

[0025] The classification of workstation types in the factory can be classified based on industry standards, or multiple workstations can be classified into one category based on the needs of practical applications, and the same category identification marks can be assigned to the workstations classified into one category. For example, the factory can be divided into stamping stations, milling stations and assembly stations. Different handling robots can be set up at different stations to carry the corresponding raw materials and finished products. For example, for the stamping station, the corresponding handling robot needs to carry the stamping raw material (steel plate), and transport the stamped finished product of the stamping station to the next production Station. Her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com