Scheduling and optimizing method for beer production

A production scheduling and optimization method technology, applied in the direction of instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as difficulties and lack of large-scale model solving capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] A beer production scheduling optimization method, the method specifically includes the following steps:

[0061] Step 1: Obtain the processing time, upper and lower limits of processing capacity, upper limit of storage capacity, and operation output / consumption ratio coefficient of beer production equipment. These equipment performance indicators are obtained through equipment manufacturers or statistics during production; beer production equipment includes gelatinization pots, mash tuns, lauter tuns, boiling pots and fermenters;

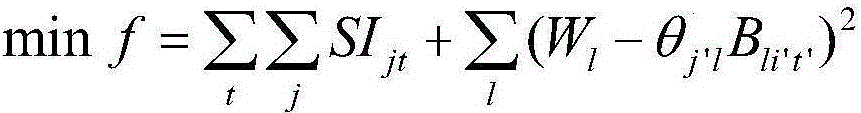

[0062] Step 2: Determine the production scheduling target according to the market demand and the production plan of the beer company, that is, the finished product demand of each type of beer and the required total scheduling time T. While determining the production target, determine the current production status of each equipment and the existing storage capacity.

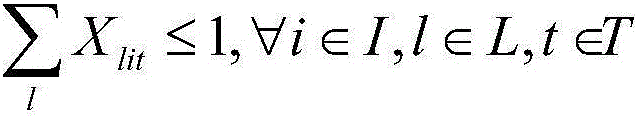

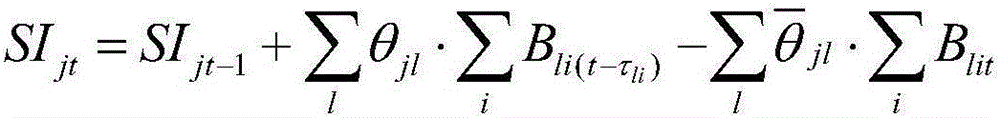

[0063] Step 3: Establish a beer scheduling production model based on discre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com