ACP1000 anti-vibration bar assembly for nuclear power plant and production method thereof

A production method and technology of anti-vibration strips, which are applied in the direction of detailed information of nuclear power plants, nuclear power plants, nuclear power generation, etc., can solve the problems of increasing the danger of maintenance personnel being exposed to radioactive radiation, waste of manpower, financial resources and events, etc., to avoid crystal grains The effect of excessive gradient, increased purity, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

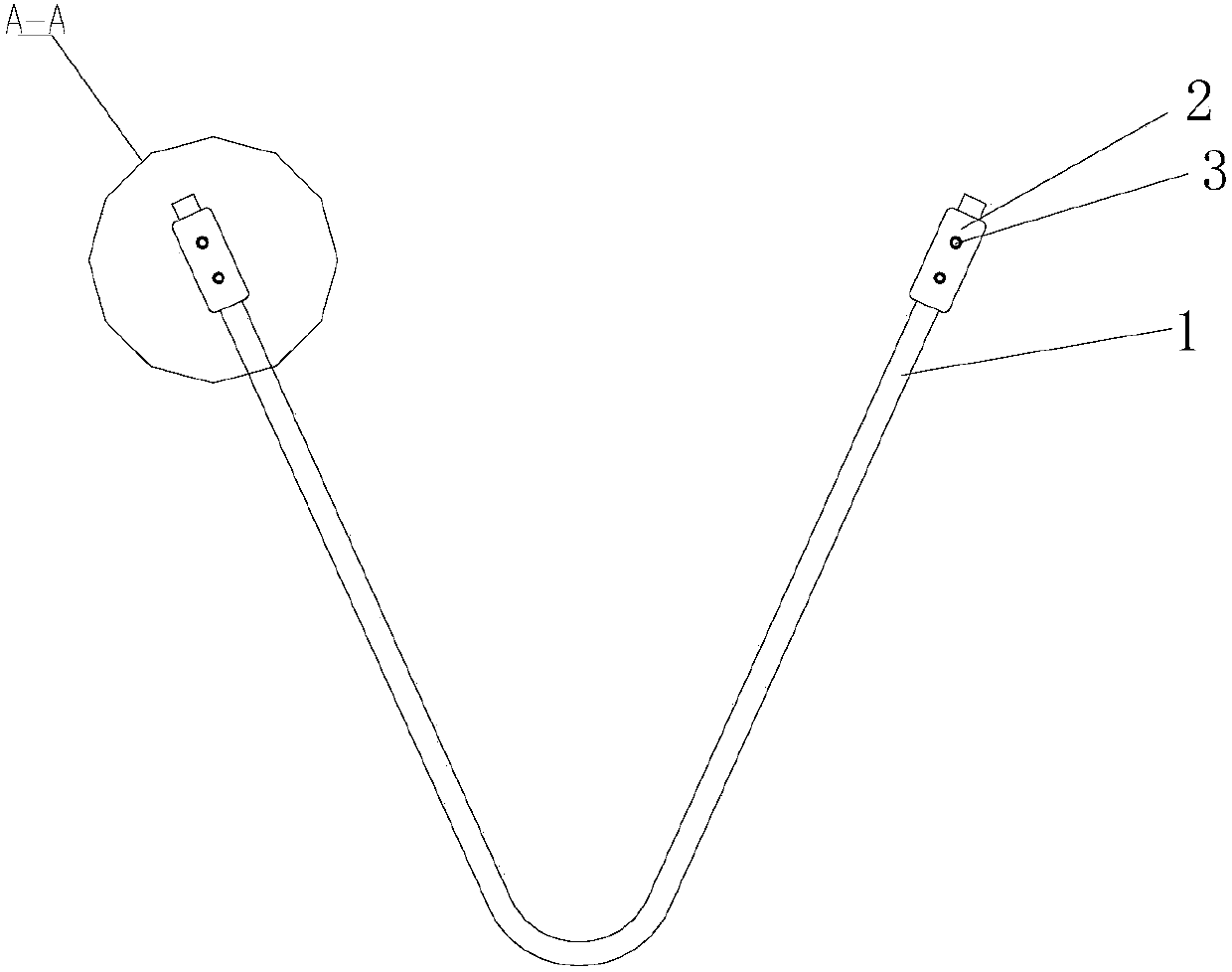

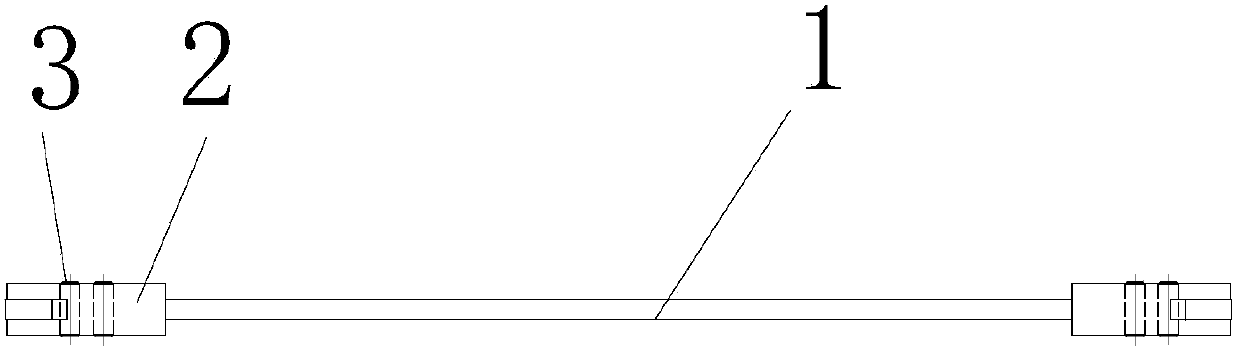

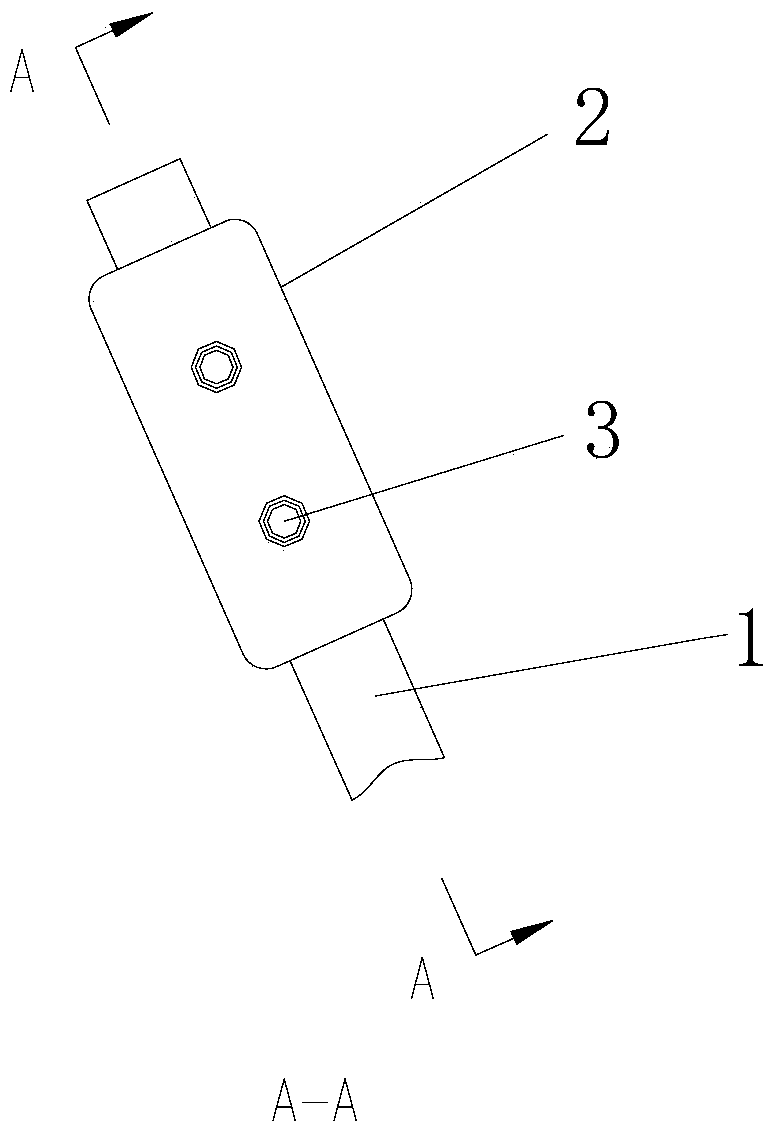

[0043] See Figure 1-2 , an ACP1000 anti-vibration bar assembly in this embodiment, comprising: an anti-vibration bar 1 with a V-shaped structure, and two end caps 2 fixedly sleeved on both ends of the anti-vibration bar 1 respectively, and each end cap 2 passes through multiple A positioning pin 3 or a screw is fixed on the end of the anti-vibration bar 1.

[0044] The end cap 2 and the anti-vibration strip 1 are provided with through holes suitable for matching with the positioning pin 3 .

[0045] Or the ends of the end cap 2 and the anti-vibration bar 1 are provided with threaded holes that are threadedly engaged with the screws.

[0046] The two ends of the anti-vibration strip 1 are rectangular, and the rest are tubular. The four sides of the rectangular part are provided with chamfers, and the end cap 2 is provided with a rectangular groove matching the rectangular part, so that the end cap 2 When being sleeved, it is only limited to the end, which is convenient for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com