Moving contact clamping structure for circuit breaker

A clamping structure and moving contact technology, applied in the direction of contacts, circuits, electrical components, etc., can solve the problems of affecting the breaking time, large movement space, limited internal space, etc., to improve the current level, stable and reliable clamping, The effect of increasing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

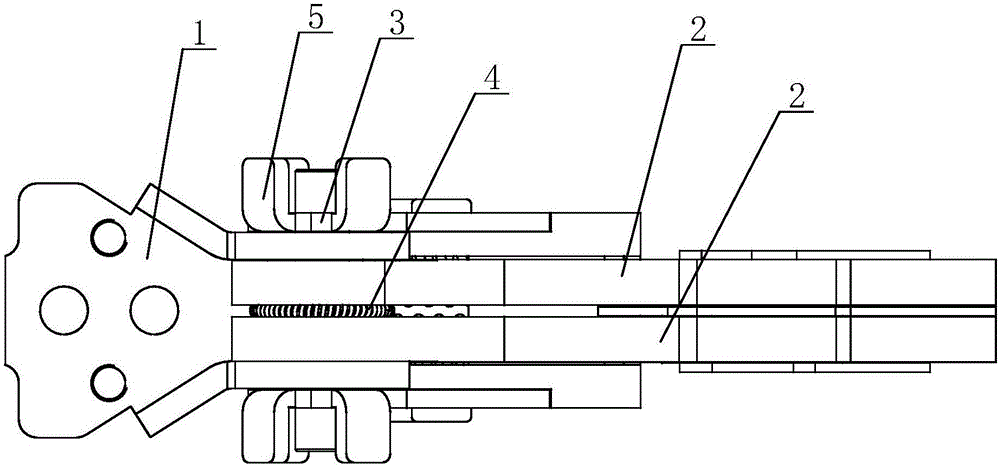

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

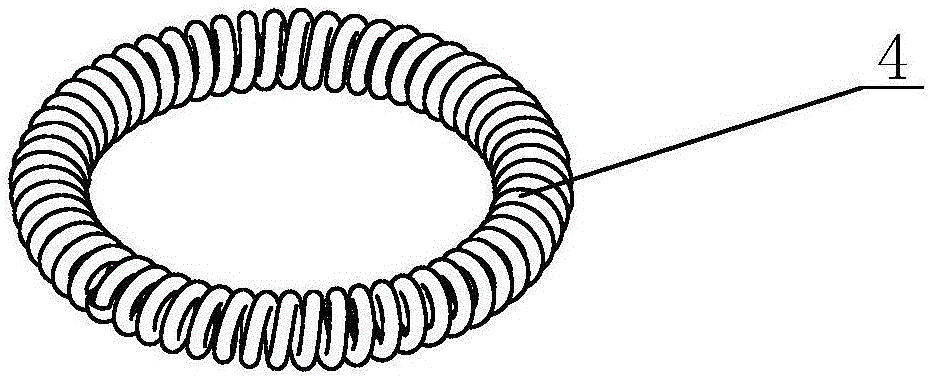

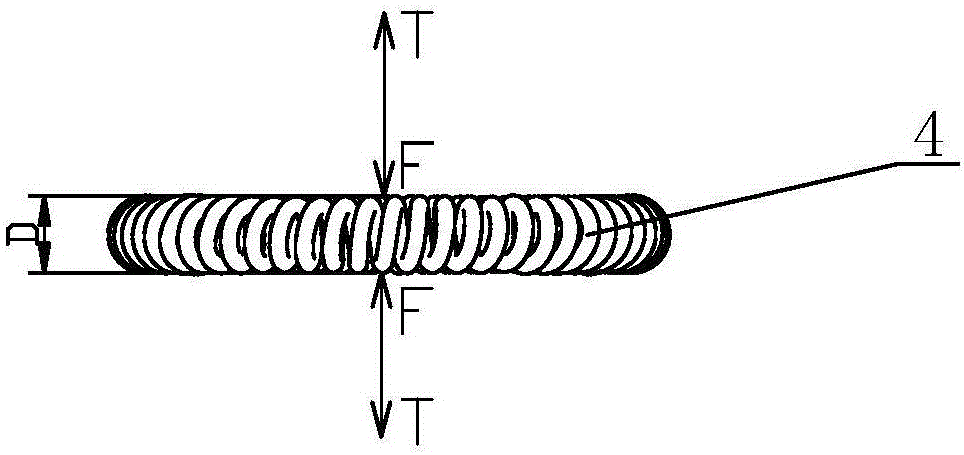

[0013] see Figure 1 to Figure 3 As shown, in this embodiment, a moving contact clamping structure of a circuit breaker includes a conductive bracket 1 and two pieces of moving contacts 2, and the two pieces of moving contacts 2 are mounted on the conductive bracket 1 through a rotating shaft 3, so that The rotating shaft 3 between the two moving contacts 2 is equipped with an elastic ring 4 that can deform along its radial direction. Limiting outer support 5.

[0014] The elastic ring 4 is welded from the end to the end of the helical spring, and is in the shape of a ring as a whole. By compressing the radial dimension of the elastic ring 4, the outer diameter of the elastic ring 4 produces a recoverable elastic deformation within the elastic range, so that The elastic ring 4 generates an elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com