Non-welded power battery module

A power battery, no welding technology, applied to battery pack components, batteries, circuits, etc., can solve the problems of module unit damage, defective products, etc., and achieve the effects of strong overall rigidity, high authenticity rate, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

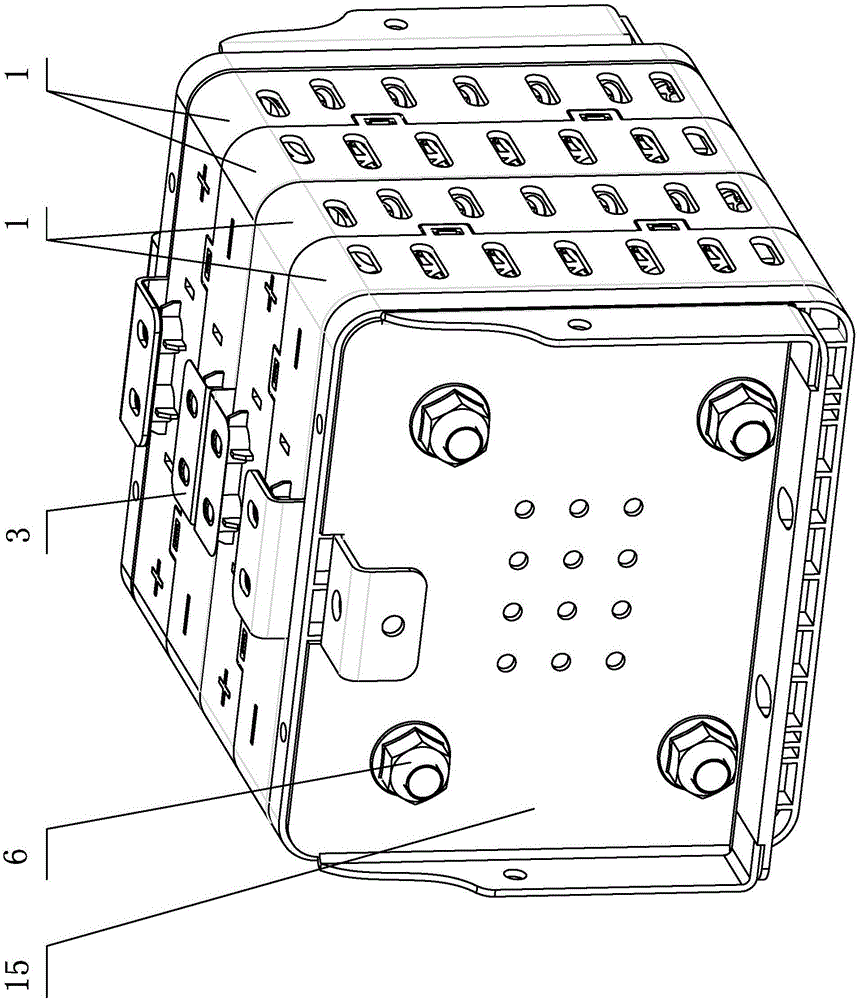

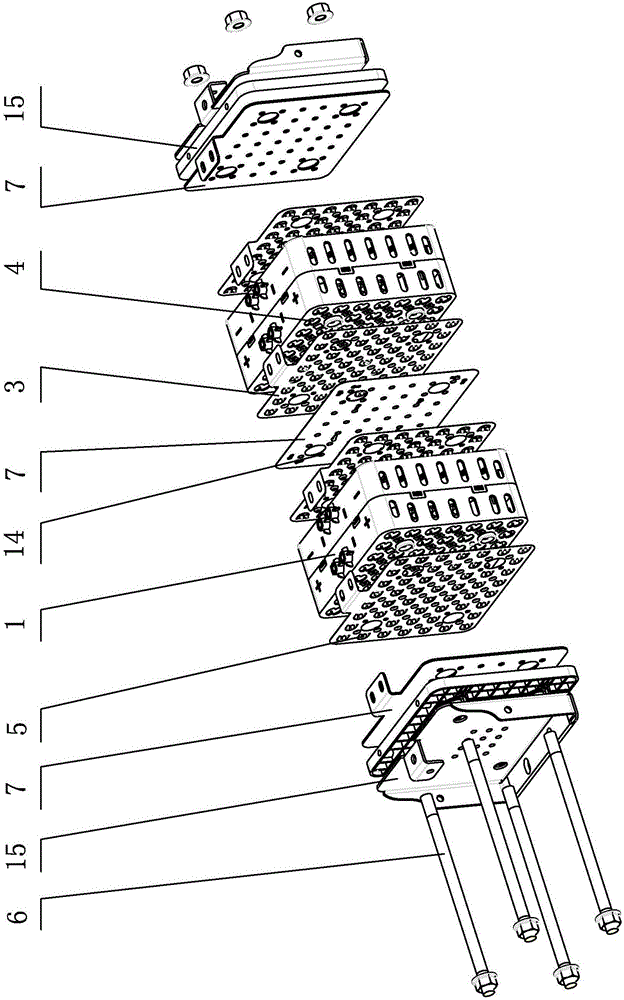

[0027] A welding-free power battery module of the present invention is assembled from multiple (2 to 8) battery module units 1, such as figure 1 shown.

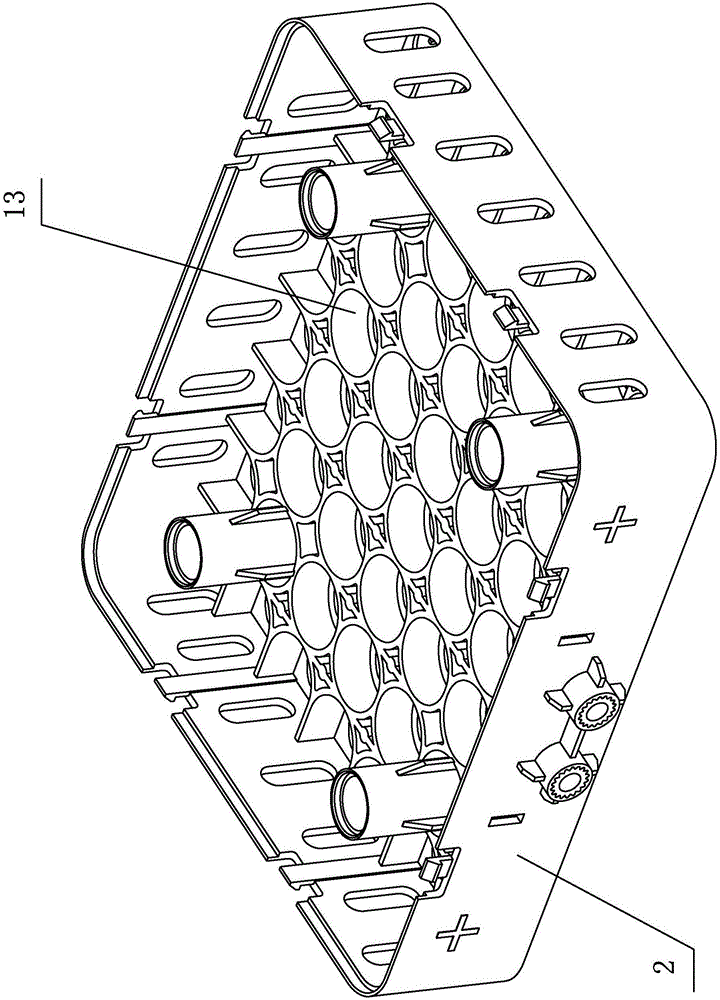

[0028] The structure of a single battery module unit 1 includes left and right buckled square battery boxes 2 (plastic boxes) and left and right electrode sheets 3 located outside the left and right battery boxes 2. Lithium batteries are positioned and installed in a matrix arrangement. In the left and right battery boxes 2, a matrix positioning sleeve 13 (for insertion of the electrode end of the lithium battery cell) is provided on the inner bottom of the battery box 2 corresponding to the matrix position of the lithium battery cell. The bottom of the positioning sleeve 13 is provided with a through hole The conductive hole 4 of the box body and the positioning sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com