Conductive connection structure for cylindrical power battery modules

A conductive connection structure and power battery technology, which is applied to battery pack parts, structural parts, circuits, etc., can solve problems such as spot welding aluminum wire falling off, battery safety hazards, etc., to reduce the use of materials, reduce safety hazards, and alleviate effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as the picture shows,

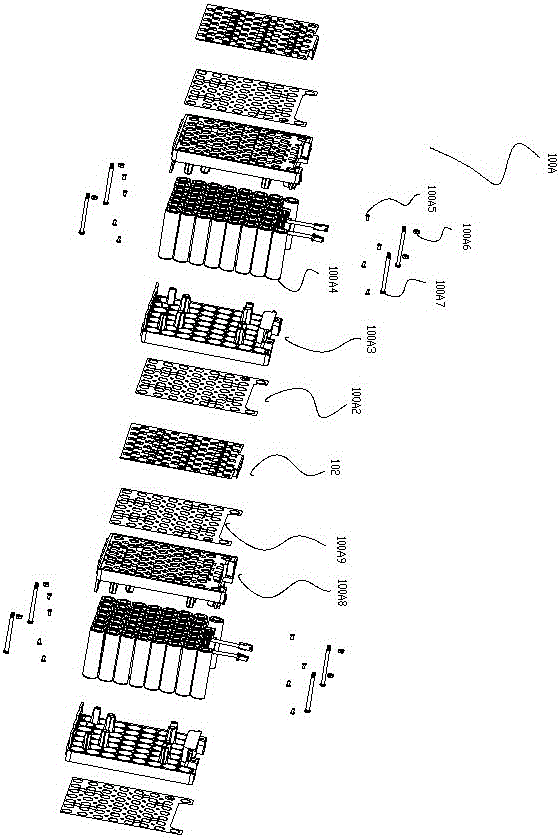

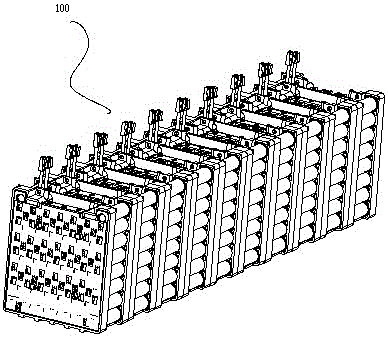

[0031] Depend on figure 1 As shown in the schematic diagram of the explosion, the conductive connection method of the battery module is: through the battery module 101 and the shrapnel type manifold 102 are pressed and assembled, and the material of the shrapnel type manifold 102 is copper plated with nickel, which is conducive to the conduction of the current with pass. Between the adjacent battery modules 100A, the conductive connection structure of the front bracket 100A3, the front nickel sheet 100A2 and the shrapnel type manifold 102, the rear nickel sheet 100A9 and the rear bracket 100A8 is adopted, and the front nickel sheet 100A2, the shrapnel type manifold 102 and the rear nickel The pieces 100A9 are compressed, and the adjacent battery modules 100A are compressed and connected by locking pieces.

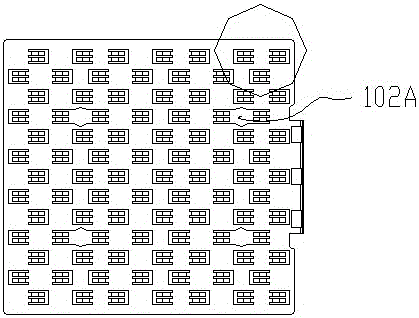

[0032] Such as image 3 , 4 , 5, and 6, the structure of the shrapnel type manifold 102 is as follows: a number of shrapnel units 102B ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com