Stepping motor loss of synchronism loss correction method based on proximity sensor

A technology of proximity sensor and stepper motor, applied in motor generator control, electrical components, control system and other directions, can solve the problems of control quantity error, control accuracy decline, stepper motor out of step, etc., to avoid output angle error. Accumulation, cost advantage, effect to ensure long-term accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

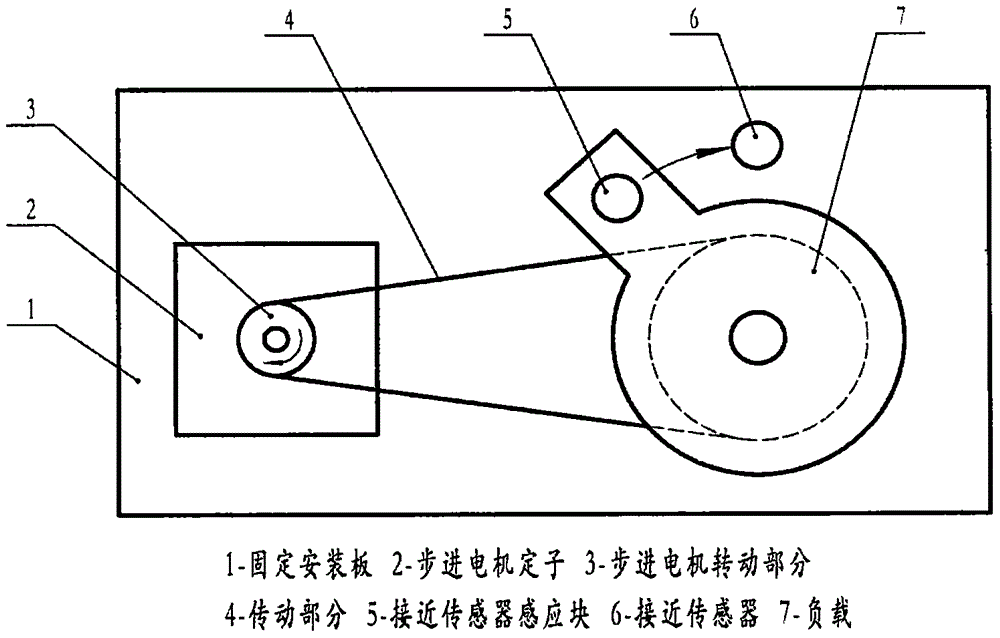

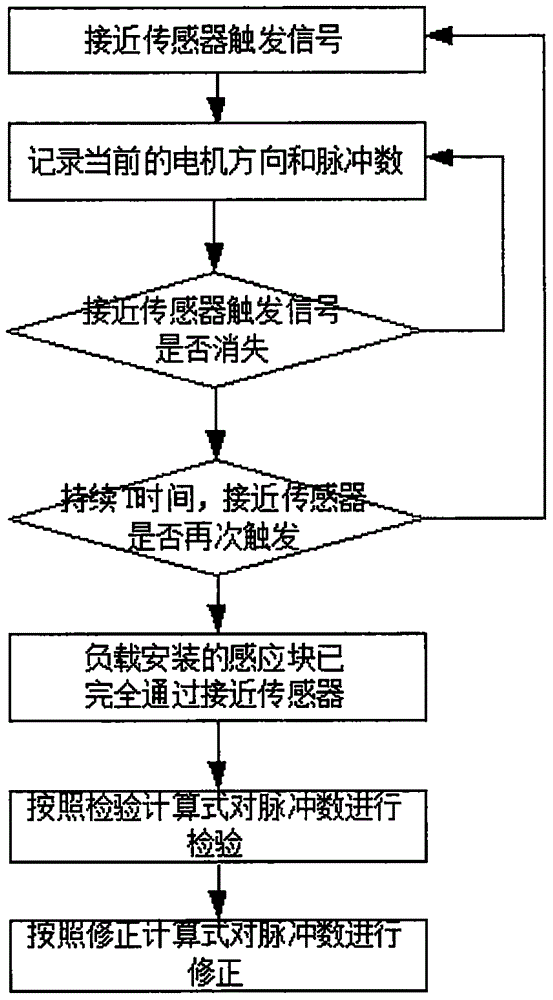

[0019] Such as figure 1 , 2 Shown, concrete method of the present invention is as follows:

[0020] 1. The whole structural design includes seven parts, fixed mounting plate, stepping motor stator part, stepping motor rotating part, structural transmission parts, proximity sensor sensing block, proximity sensor and load. The fixed mounting plate provides support for the whole structure. The stator of the stepping motor is fixed on the mounting plate, and the proximity sensor sensing block is installed on the load. The proximity sensor is fixed on the mounting plate. Whenever the proximity sensor passes the proximity sensor sensing block, the proximity sensor will transmit signal. Through the structural design, the angular position when the proximity sensor signal is triggered can be accurately marked. In this example, the marked angular position is A ideal .

[0021] 2. Due to the difference in the angular position sensed by the proximity sensor in the forward and reverse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com