Integrated crystal resonator and processing method thereof

A crystal resonator and vibrator technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of low processing efficiency of miniaturized products, low yield of resonator wafers, and difficulties in resonators, so as to save the use of conductive glue , increase profit margins, and reduce the effect of partial impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment, further illustrate the present invention.

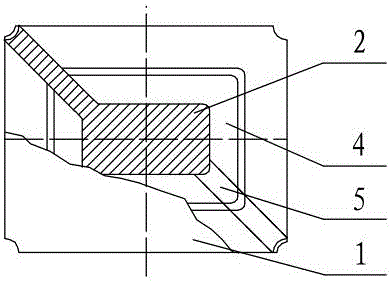

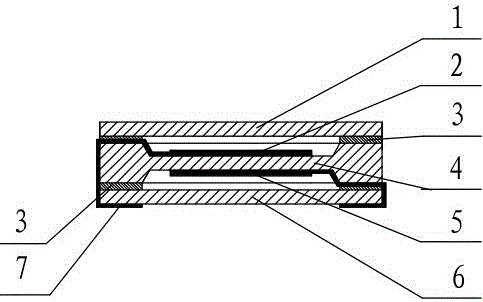

[0027] see figure 1 , figure 2 , an integrated crystal resonator, composed of a vibrator wafer base 4 and electrodes. The vibrator base is made of a piezoelectric material through a mask and chemically etched. The upper electrode 2 and the lower electrode 5 are respectively arranged in the area; the depth of the recessed area is greater than the thickness of the upper electrode 2 or the lower electrode 5; the upper electrode 2 and the lower electrode 5 are respectively provided with metal lead-out lines The top of the vibrator chip base 4 is respectively connected and fixed to the upper cover plate 1 and the lower substrate 6; the two ends of the bottom surface of the lower substrate 6 are respectively provided with pads, and the pads are connected to the metal lead wires of the upper electrode 2 or the lower electrode 5; The materials of the upper cover plate 1 , the lower substrate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com