Mixtures for Fried Food Coatings

A technology of fried food and mixture, which is applied in the field of mixture for fried food coating, which can solve the problem that the coating is easy to lose its taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

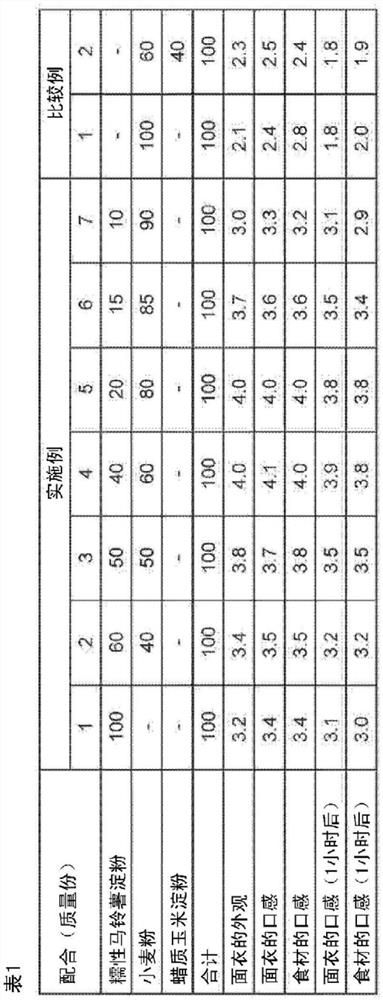

[0024] Using waxy potato starch (amylopectin content is more than 99% by mass) and wheat flour (thin powder flour: manufactured by Nissin Foods), they were mixed with the formulation (parts by mass) shown in Table 1, and Examples 1 to 7 were produced respectively. fried food coating with mixture.

Embodiment 8~17

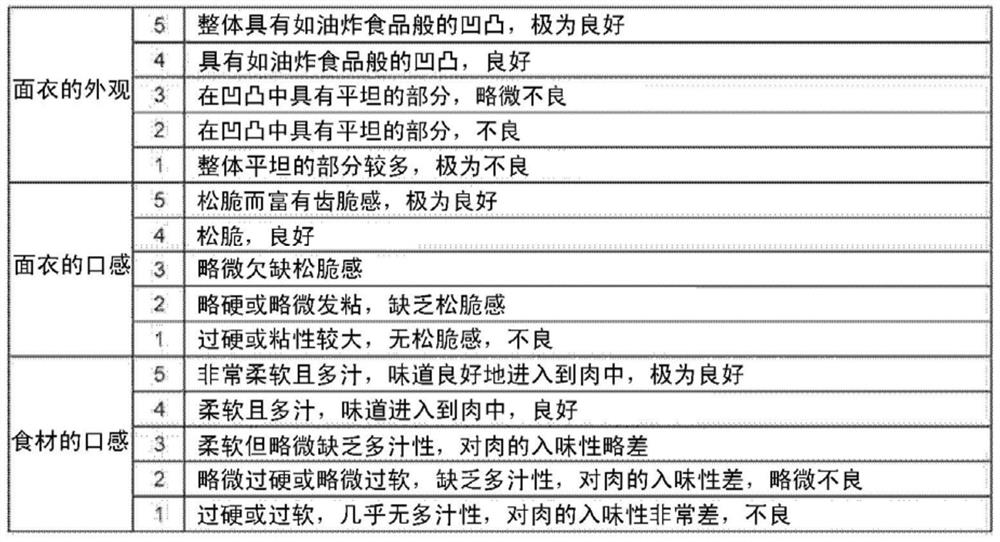

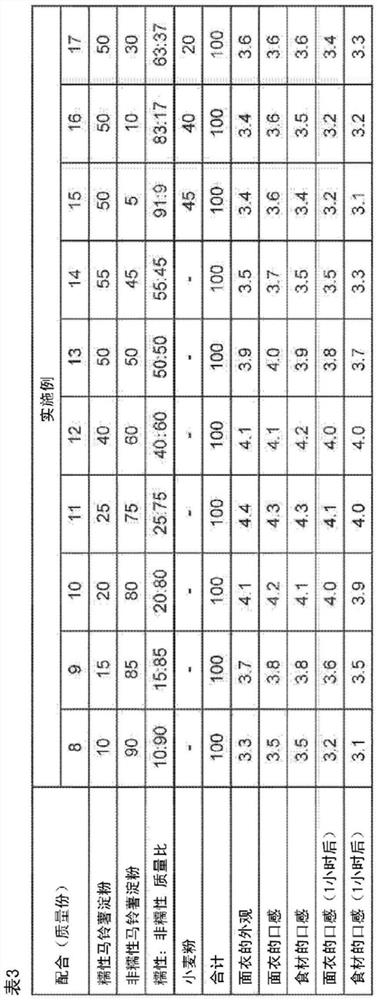

[0035] The raw materials shown in Table 3 were uniformly mixed to prepare the deep-fried food batter mixtures of Examples 8 to 17, respectively. Using this, fried foods were produced in the same manner as in Test Example 1. Furthermore, the amylopectin content of non-waxy potato starch is about 75%. Ten special judges were asked to evaluate the quality of the freshly fried fried food and the fried food left at room temperature (about 25°C) for 1 hour on the basis of the evaluation criteria in Table 2. The results are shown in Table 3.

[0036]

Embodiment 18~24

[0038] The raw materials shown in Table 4 were uniformly mixed to prepare the deep-fried food coating mixtures of Examples 18 to 24, respectively. Using this, fried foods were produced in the same manner as in Test Example 1. Furthermore, the amylopectin content of non-waxy potato starch is about 75%. Ten special judges were asked to evaluate the quality of the freshly fried fried food and the fried food after leaving it at room temperature (about 25°C) for 1 hour on the basis of the evaluation criteria in Table 2. The results are shown in Table 4.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com