Rubber composition, crosslinked rubber composition and tire

A technology of rubber composition and cross-linked rubber, used in special tires, carbon compounds, tire parts, etc., can solve the problems of low heat generation and reduced cutting resistance, and achieve low heat generation, high Low fatigue cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] A more detailed illustration of the invention is provided below by way of examples. However, the present invention is by no means limited by the following examples.

[0076] (carbon black)

[0077] Carbon Blacks 1-12 having the parameters shown in Table 1 were prepared. Carbon blacks 1, 2, 6-10 and 12 were produced by using fine particle size, high structure HAF carbon black produced by Asahi Carbon Co., Ltd. and by adjusting reaction temperature, air rate, amount of KOH and reaction time. For carbon blacks 3-5 and 11, parameters were changed by adjusting production conditions for fine particle size, low structure HAF carbon black produced by Asahi Carbon Co., Ltd.

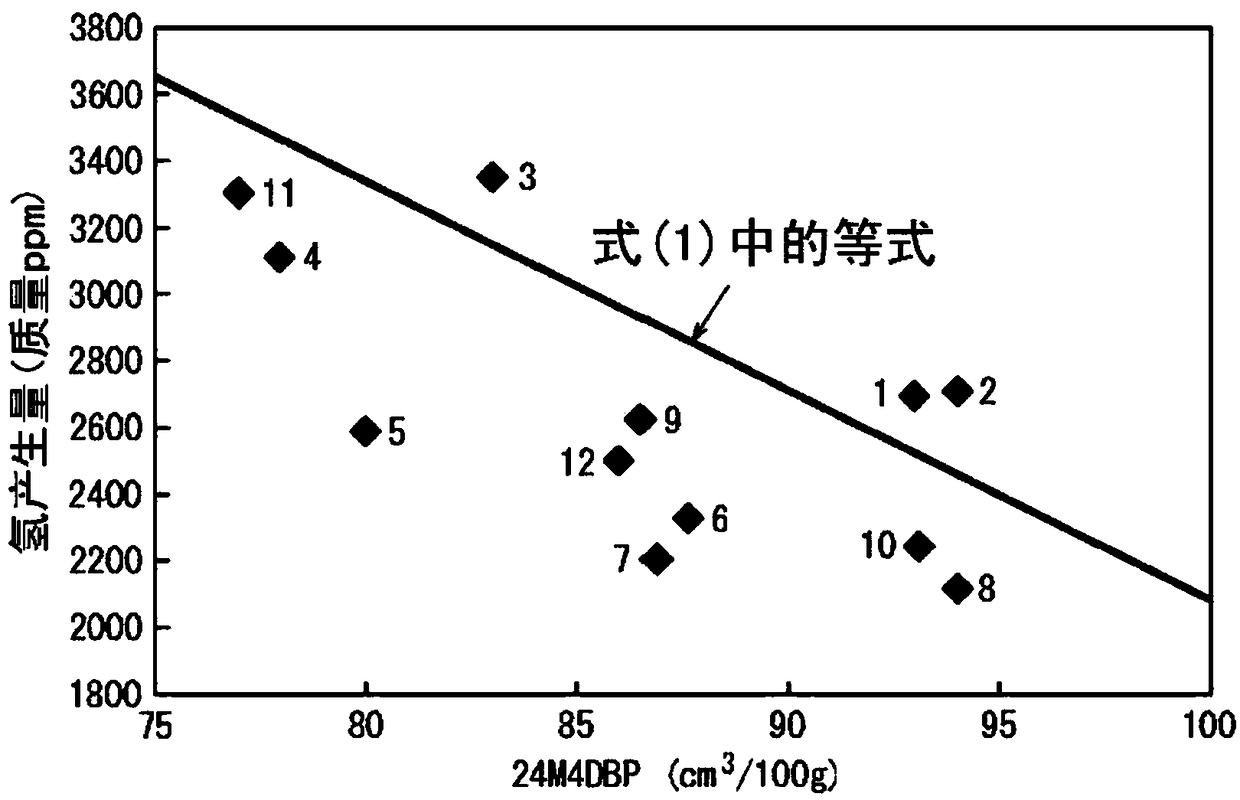

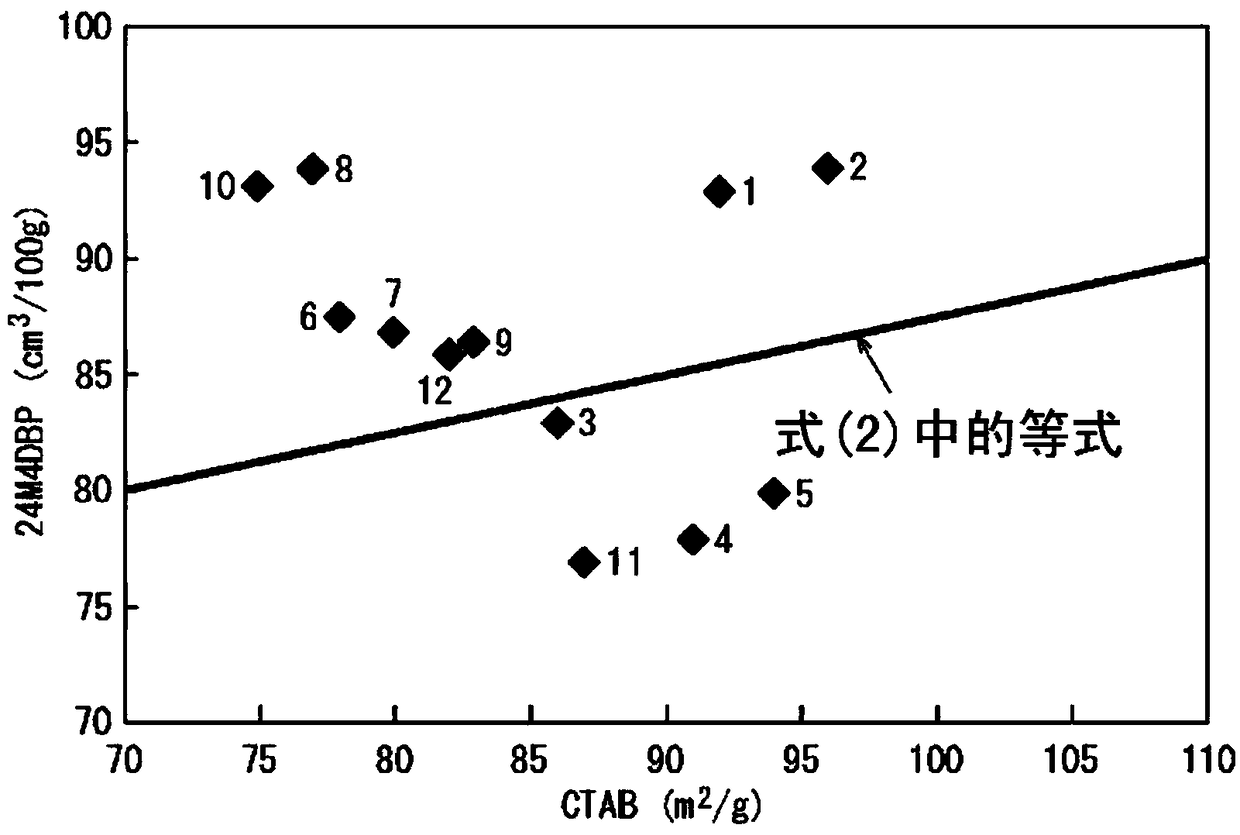

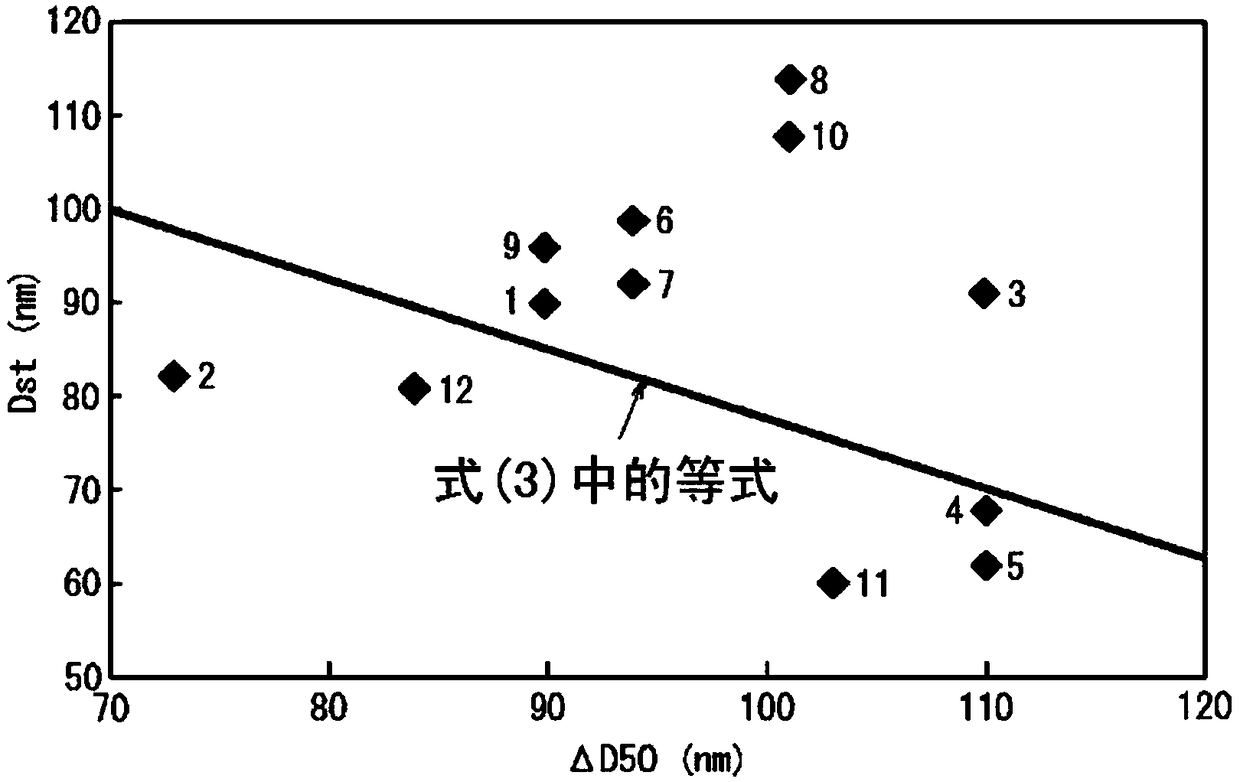

[0078] CTAB and 24M4DBP in Table 1 were measured according to JIS K 6217-3 and JIS K 6217-4, respectively. In addition, Dst and ΔD50 were measured by a centrifugal sedimentation method using a disc centrifuge manufactured by Joyce-Loebl. The hydrogen generation amount of carbon black was obtained by mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com