Corn seedling weeding mechanism with synchronized running of stretching and rolling of weeding tooth roll

A technology of synchronous operation and corn seedlings, applied in the field of agricultural machinery, can solve the problems of high seedling damage rate, low operation efficiency, complex mechanism, etc., and achieve the effects of low seedling damage rate, less use failure, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

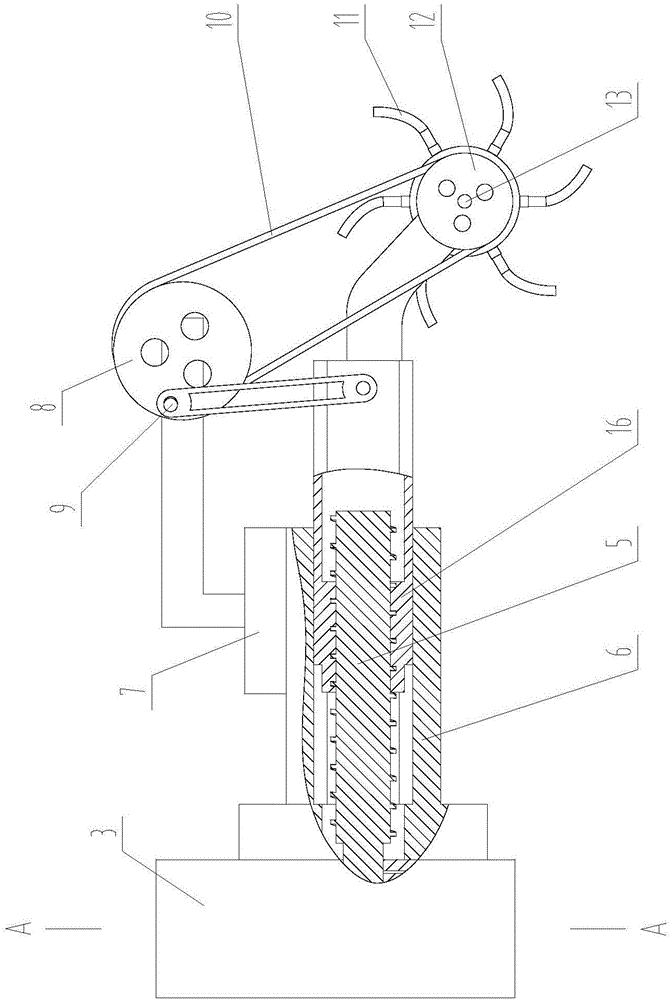

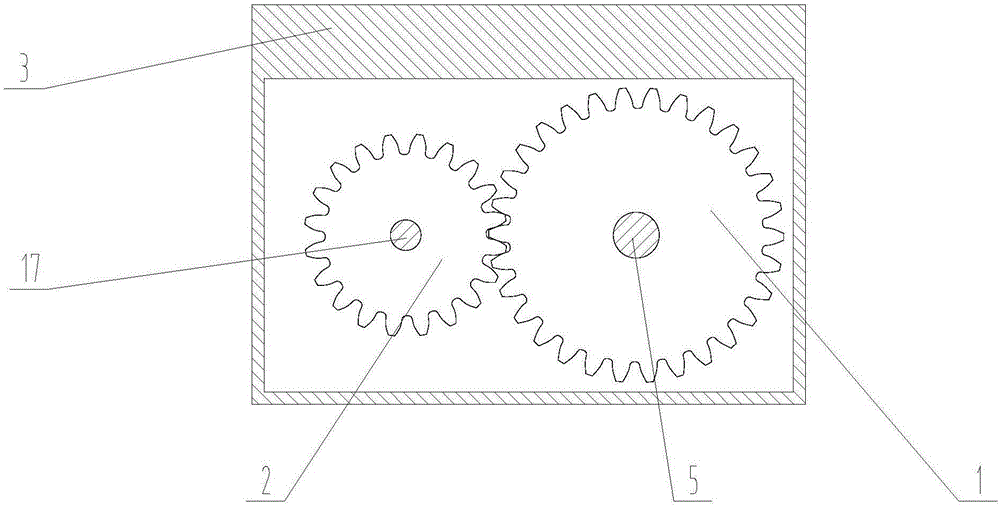

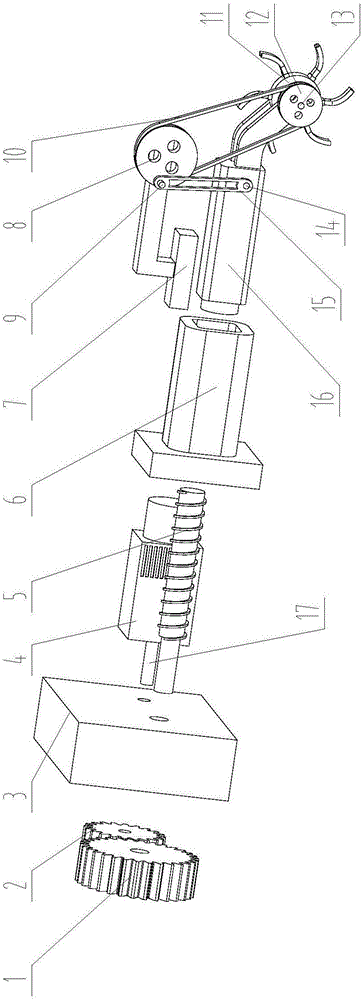

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A weeding mechanism between corn seedlings in which the weeding gear rolls telescopically and rolls synchronously, and a stepping motor 4 is fixed on the outer side of the gear box 3, and the motor shaft 17 of the stepping motor 4 is rotatably inserted into the gear box 3, the screw 5 and the motor shaft 17 are parallel to each other and are rotatably fitted on the gear case 3, and the driving cylindrical gears that mesh with each other are respectively fixed on the motor shaft 17 and the screw 5 and located inside the gear case 3 2 and the driven cylindrical gear 1, the housing 6 is sleeved on the outside of the screw 5, the housing 6 is fixed on the outer side of the gear box 3, and the inner threaded cylindrical telescopic arm 16 can be axially telescopically moved In the casing 6, the screw rod 5 is threadedly connected with the internally threaded c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com