A kind of composite rubber glove and preparation method thereof

A technology for compounding rubber and gloves, applied in the field of compound rubber gloves and their preparation, can solve the problems to be improved, and achieve the effects of low tensile stress, high air permeability, and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

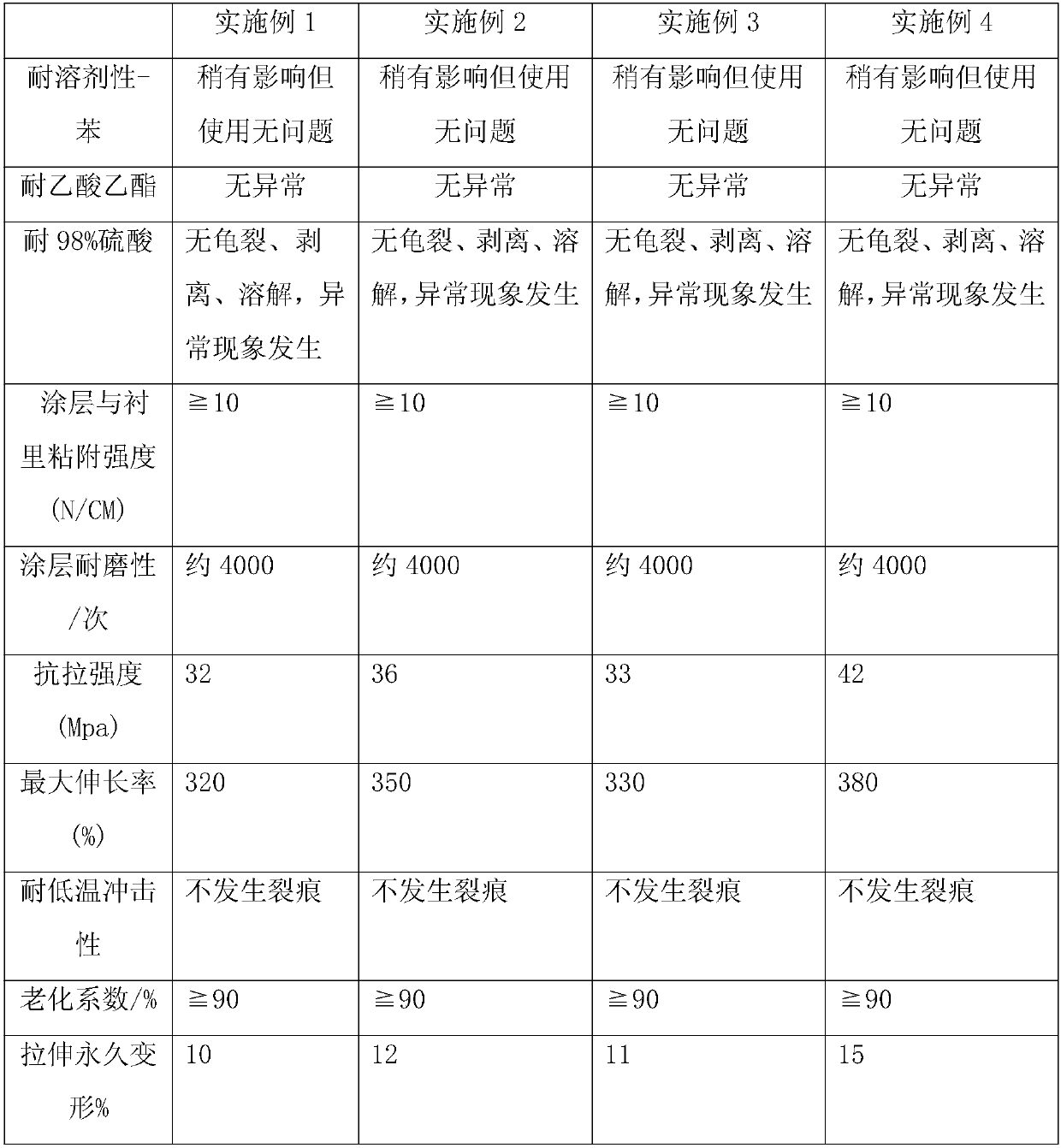

Examples

Embodiment 1

[0023] A preparation method for composite rubber gloves, comprising the steps of:

[0024] (1) Ingredients: 90 parts by weight of polyvinyl chloride, 1.5 parts of accelerator CZ, 10 parts of plasticizer dibutyl adipate, 60 parts of ethyl acetate to prepare polyvinyl chloride slurry; according to 90 parts of nitrile rubber 3 parts, 3 parts of colloidal sulfur, 1.5 parts of accelerator N-ethyl N-phenyl zinc dithiocarbamate, 30 parts of carboxymethyl cellulose, 60 parts of ethyl acetate to prepare nitrile latex;

[0025] (2) Slurry dipping: put the fiber glove lining on the assembly line mold after surface treatment, then immerse it in the above-mentioned prepared nitrile latex, vulcanize at 160°C for 60 minutes, and then bake at 120°C Dry for 60 minutes;

[0026] (3) Spraying: Spray the crude glove after drying in step (2) with the polyvinyl chloride slurry configured above, and heat for 60 minutes at a temperature of 110° C.;

[0027] (4) Slurry dipping: Cool the crude gloves...

Embodiment 2

[0029] A preparation method for composite rubber gloves, comprising the steps of:

[0030] (1) Ingredients: 70 parts by weight of polyvinyl chloride, 0.5 part of accelerator CZ, 4 parts of plasticizer dibutyl adipate, 30 parts of ethyl acetate to prepare polyvinyl chloride slurry; according to 70 parts of nitrile rubber 1 part, 1 part of colloidal sulfur, 0.5 part of accelerator N-ethyl N-phenyl zinc dithiocarbamate, 20 parts of carboxymethyl cellulose, 30 parts of ethyl acetate to prepare nitrile latex;

[0031] (2) Slurry dipping: put the fiber glove lining on the assembly line mold after surface treatment, then immerse in the above-mentioned prepared nitrile latex, vulcanize at 110°C for 30 minutes, and then bake at 80°C Dry for 30 minutes;

[0032] (3) Spraying: Spray the crude glove product after drying in step (2) with the polyvinyl chloride slurry configured above, and heat for 30 minutes at a temperature of 90° C.;

[0033] (4) Slurry dipping: Cool the rough gloves f...

Embodiment 3

[0035] A preparation method for composite rubber gloves, comprising the steps of:

[0036] (1) Ingredients: 80 parts by weight of polyvinyl chloride, 1 part of accelerator NS, 6 parts of plasticizer dibutyl adipate, 40 parts of ethyl acetate to prepare polyvinyl chloride slurry; according to 80 parts of nitrile rubber, 2 parts of colloidal sulfur, 1 part of accelerator N-ethyl N-phenyl zinc dithiocarbamate, 25 parts of carboxymethyl cellulose, 40 parts of ethyl acetate to prepare nitrile latex;

[0037] (2) Slurry dipping: Put the fiber glove lining on the assembly line mold after surface treatment, then immerse it in the above-mentioned prepared nitrile latex, vulcanize at 130°C for 45 minutes, and then bake at 100°C Dry for 45 minutes;

[0038] (3) Spraying: Spray the crude glove after drying in step (2) with the polyvinyl chloride slurry prepared above, and heat for 45 minutes at a temperature of 100° C.;

[0039] (4) Slurry dipping: Cool the rough gloves fully solidified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com