Efficient air filtering module used on heating pipeline

A high-efficiency filtration and heating pipeline technology, applied in the field of air purification, can solve problems such as adverse effects on the human body, achieve the effect of eliminating harmful components and odors, and the structure design is simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

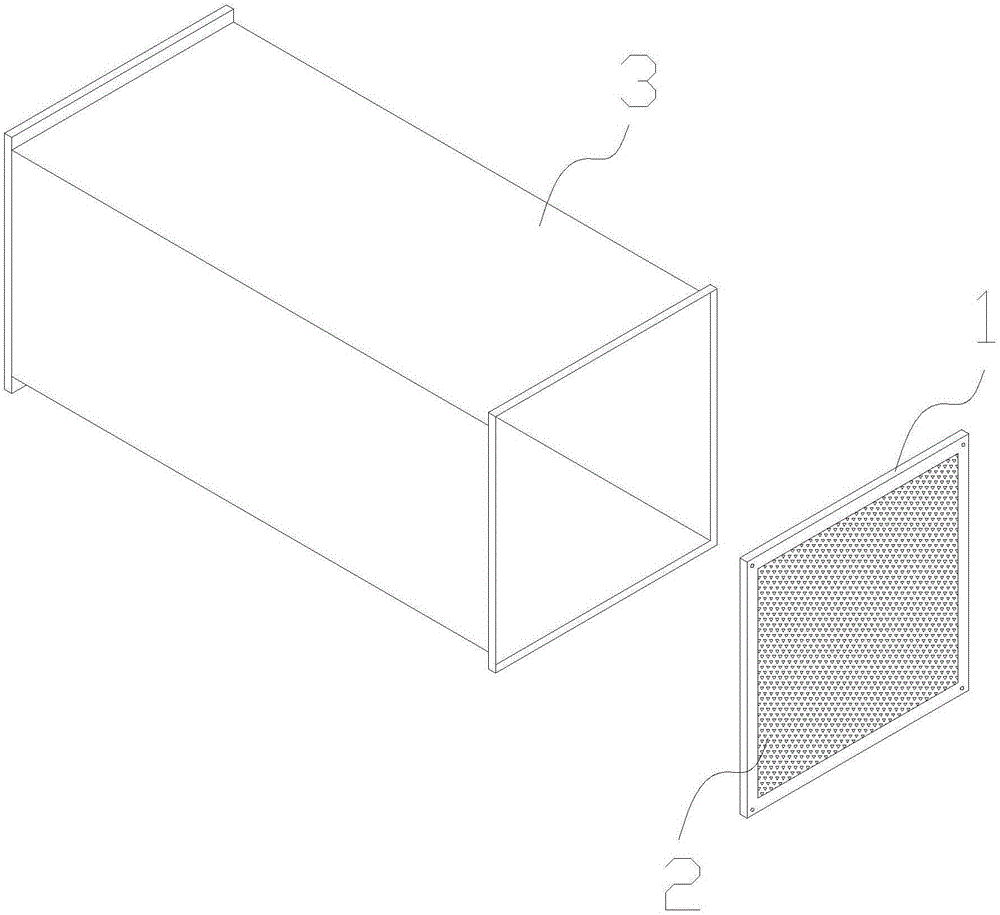

[0028] Such as figure 1 As shown, a high-efficiency air filter module for heating pipes includes a frame 1, which is connected to the air inlet of the warm air pipe 3, and a porous metal foam plate 2 is arranged in the frame 1, and its porosity reaches About 90%, the air can pass through smoothly. The surface of the porous metal foam plate 2 is provided with a layer of air purifier layer. The air purifier layer is obtained by drying the porous metal foam plate 2 after soaking in the air purifier. Forming; drying is to use circulating hot air to dry, so that the circulating hot air passes through the porous metal foam plate, and the inner wall of the gap is also dried, and the gap of the porous metal foam plate will not be blocked by the action of the wind force, and the temperature of the hot air is controlled at 65-82°C;

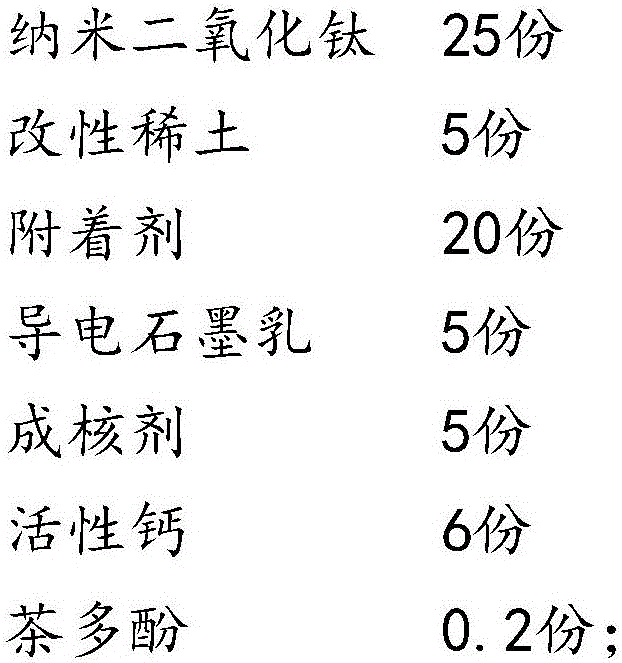

[0029] Described air purifier is made up of the component of following parts by weight:

[0030]

[0031] The preparation method of the air purifier i...

Embodiment 2

[0045] Such as figure 1As shown, a high-efficiency air filter module for heating pipes includes a frame 1, which is connected to the air inlet of the warm air pipe 3, and a porous metal foam plate 2 is arranged in the frame 1, and its porosity reaches About 90%, the air can pass through smoothly. The surface of the porous metal foam plate 2 is provided with a layer of air purifier layer. The air purifier layer is obtained by drying the porous metal foam plate 2 after soaking in the air purifier. Forming; drying is to use circulating hot air to dry, so that the circulating hot air passes through the porous metal foam plate, and the inner wall of the gap is also dried, and the gap of the porous metal foam plate will not be blocked by the action of the wind force, and the temperature of the hot air is controlled at 65-82°C;

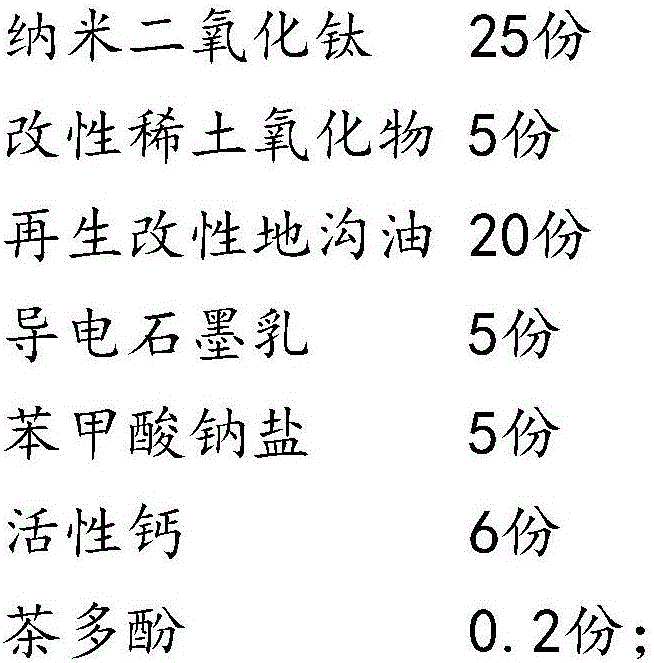

[0046] Described air purifier is made up of the component of following parts by weight:

[0047]

[0048] The preparation method of the air purifier is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com