Laser nozzle for metal powder laser forming

A laser forming and metal powder technology, applied in the direction of improving process efficiency, improving energy efficiency, additive manufacturing, etc., can solve the problems of unstable metal powder laser forming quality, poor powder ejection effect, complex nozzle structure, etc., to achieve excellent The effect of quality, easy operation and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

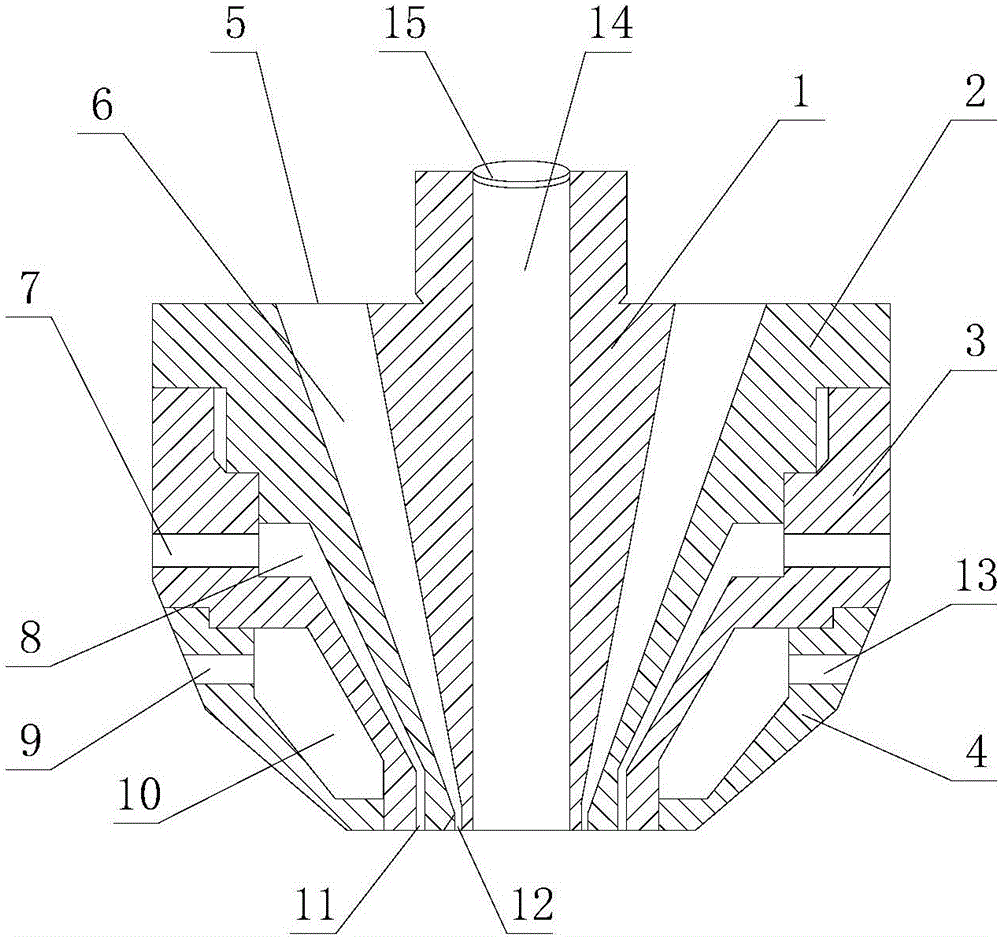

[0011] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0012] Such as figure 1 The laser nozzle shown for metal powder laser forming includes an inner tube 1, and the inner cavity of the inner tube 1 is a laser channel 14, and the inner tube 1 is sequentially provided with a powder feeding sleeve 2, an air flow sleeve 3 and an outer cooling sleeve 4, and the inner tube 1 A powder channel 6 is formed between 1 and the powder feeding sleeve 2, and a gas channel 8 is formed between the powder feeding sleeve 2 and the air flow sleeve 3; the inner tube 1, the powder feeding sleeve 2, the air flow sleeve 3 and the outer cooling sleeve 4 are coaxially arranged , the upper end of the laser channel 14 is equipped with a condenser lens 15; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com