Special-shaped metal inner hole workpiece surface nanometer machining device and application thereof

A special-shaped metal and processing device technology, which is applied in the field of nano-processing devices for the surface of special-shaped metal inner hole workpieces, can solve problems such as difficulty in nano-processing the inner hole surface, achieve good economic benefits and market value, has remarkable effects, and improves processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

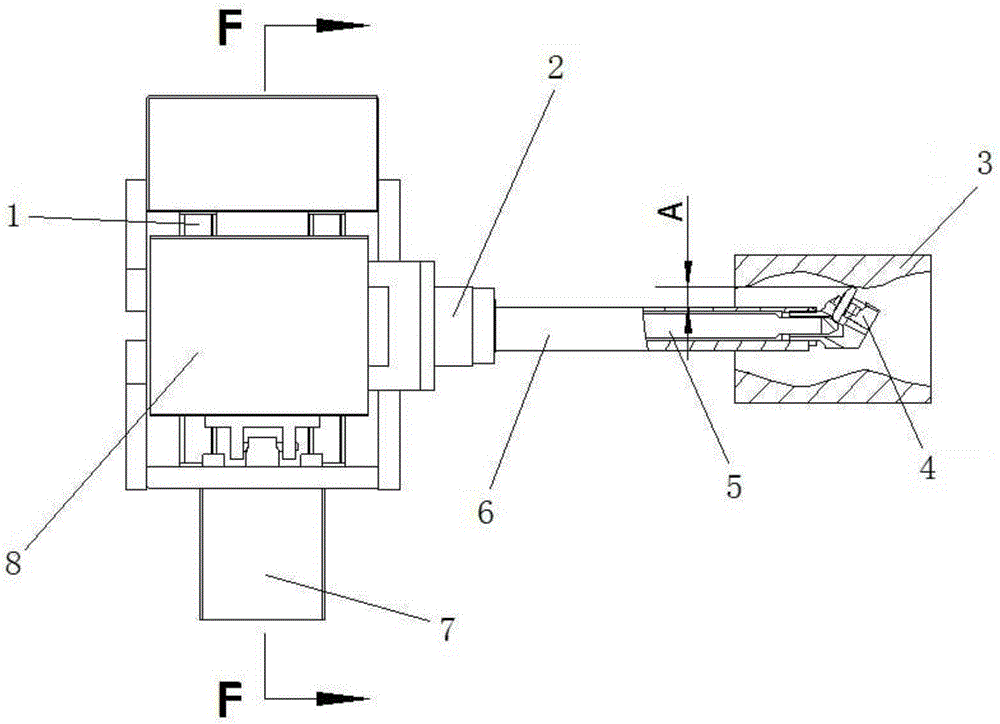

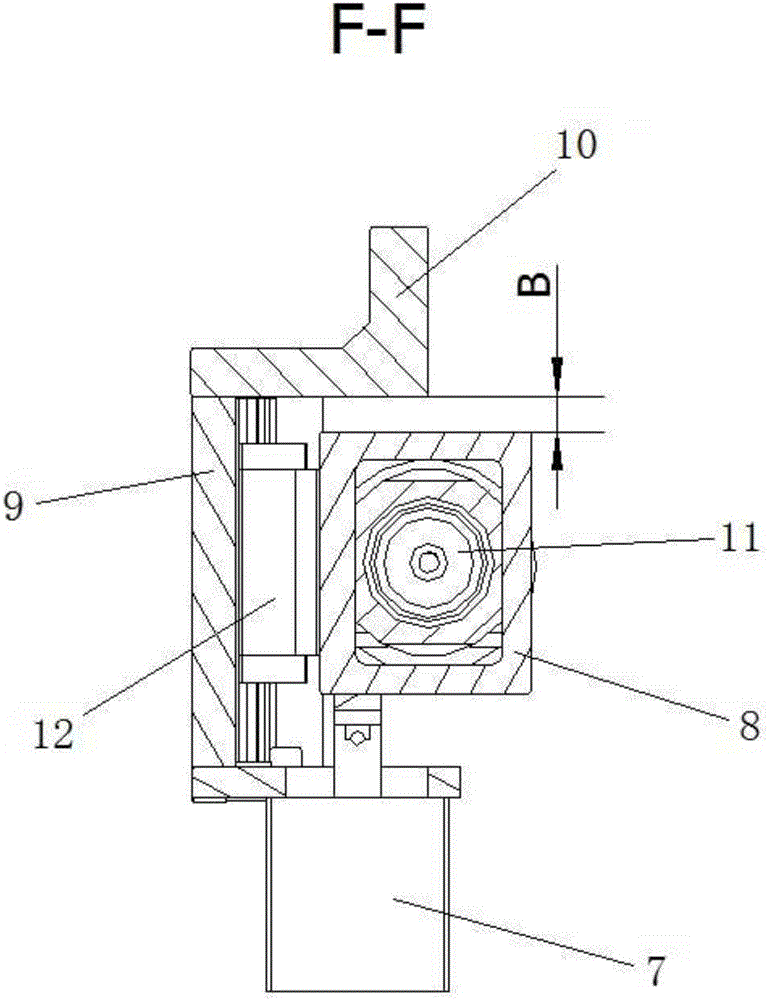

[0026] Such as figure 1 and figure 2 As shown, the present embodiment provides a nano-processing device for the surface of a special-shaped metal inner hole workpiece, including a connecting seat 9 and a sliding device arranged on the connecting seat 9, the sliding device is provided with an ultrasonic machining tool 2, and a part of the connecting seat 9 A cylinder 7 is arranged on the side, and one end of the cylinder rod of the cylinder 7 is connected with the ultrasonic machining tool 2 .

[0027] Wherein, the sliding device adopts a slide block 12 , the connecting seat 9 is provided with a guide rail 1 matched with the slide block, and the slide block 12 is installed on the guide rail 1 .

[0028] A pressing block 10 is provided on the other side of the connecting seat 9 , and the pressing block 10 and the connecting seat 9 are integrally structured. The function of the pressing block is to connect and fix the device with the machine tool for easy installation.

[002...

Embodiment 2

[0036] This embodiment provides a device for nano-processing the surface of a special-shaped metal inner hole workpiece, the structure of which is as described in Embodiment 1, the difference is that the pressing block 10 and the connecting seat 9 are of a split structure. The top of the tool head is 20mm higher than the outer edge of the support cylinder 6 .

[0037] The connecting seat 9 is provided with a slide groove matched with the slide block 12, and the bottom end of the slide block 12 is embedded in the slide groove and can slide along the slide groove.

Embodiment 3

[0039] A working method of the device for nano-processing the surface of a special-shaped metal inner hole workpiece as described in embodiment 1, comprising the following steps,

[0040] Firstly, install the nano-processing device on the surface of the special-shaped metal inner hole workpiece on the tool holder of the machine tool, and then extend the tool head 4 into the special-shaped metal inner hole workpiece 3, so that the tool head is attached to the surface of the special-shaped metal inner hole; start the machine tool, the cylinder 7 and the transducer 11 work, the tool holder drives the device of the present invention to move when the tool holder moves linearly in the axial direction of the machine tool spindle, and the transducer 11 transmits energy to the tool head through the horn to realize the tool head's contact with the surface of the special-shaped metal inner hole Nano-processing, during the processing, the tool head can always be kept in contact with the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com