Valve lock piece with material automatic dial type pressure head

A valve lock plate and pressure head technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of poor quality and low efficiency of valve stems, achieve compact internal space, reduce working intensity, and good system compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

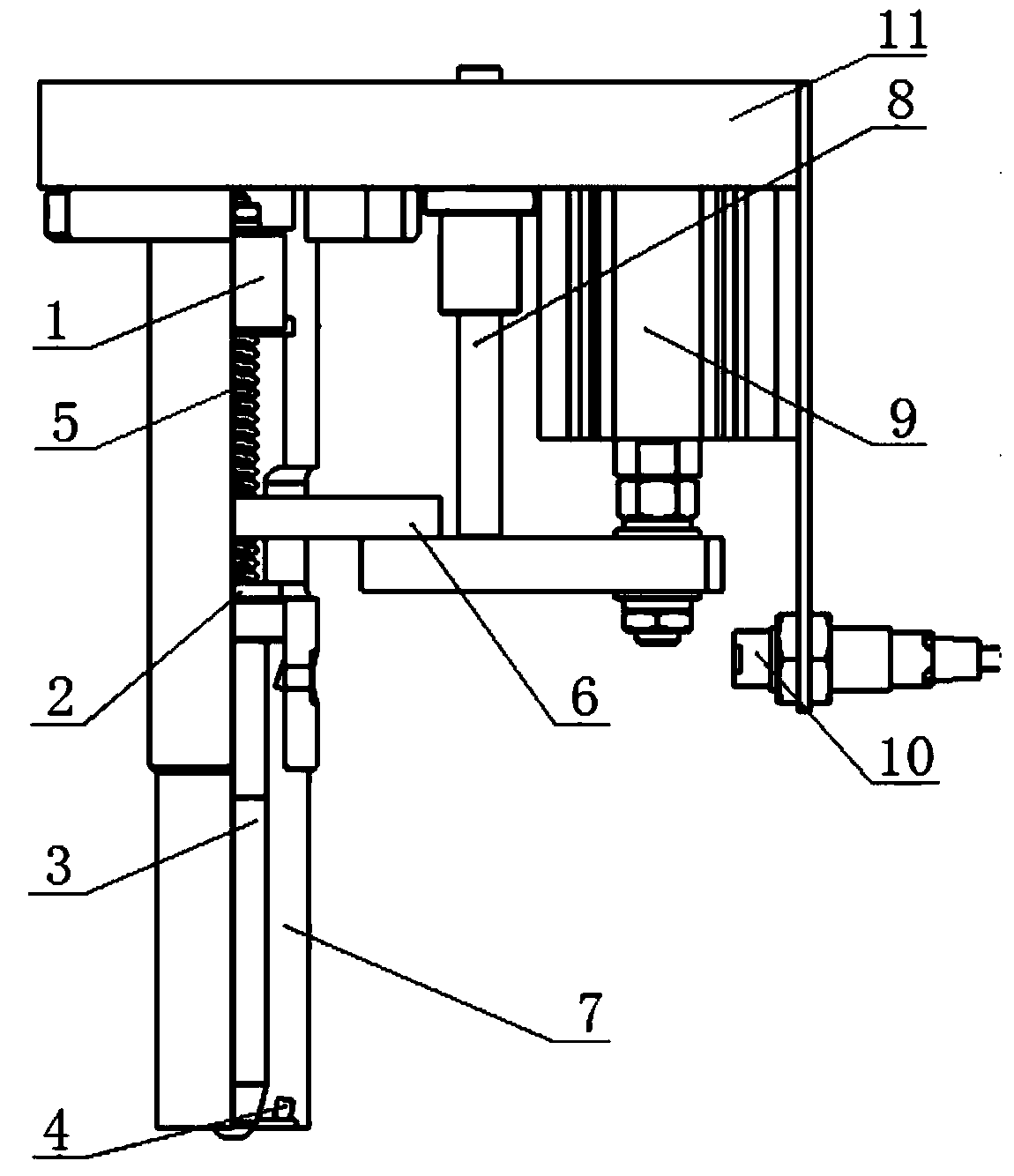

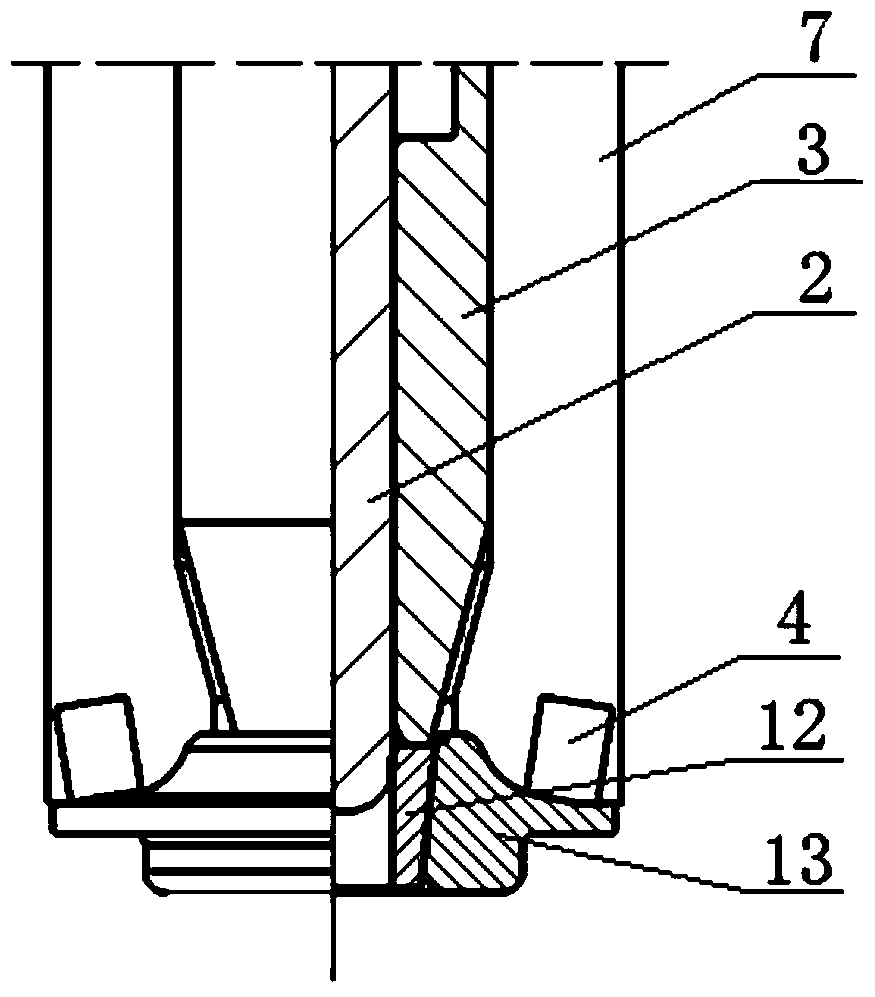

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] Such as Figure 1-2 As shown, a kind of automatic dial-mounted indenter with material for the valve lock plate provided by the present invention includes a top core 2, a dial sleeve 3, a permanent magnet 4, a spring 5, a dial 6, an indenter body 7 and a driving device, wherein The indenter body 7 is a hollow structure, the upper end of the indenter body 7 is connected to the base plate 11 of the lock plate press machine, and a plurality of permanent magnets 4 are arranged at the lower end, and the permanent magnets 4 are used for magnetically attracting the valve lock plate 12 The valve spring seat 13. The dial sleeve 3 and the top core 2 are sequentially inserted into the cavity of the indenter body 7 from the outside to the inside, and the dial sleeve 3 and the top core 2 can slide relatively, and the spring 5 is housed in the The cavity of the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com