Single-corrugated two-layer paperboard production equipment

A production equipment, single corrugated technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems that the flatness of the cardboard is difficult to meet customer needs, affect the quality of the cardboard, and the wrinkle and deformation of the cardboard, so as to enhance the automatic bonding ability, reduce wrinkles, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

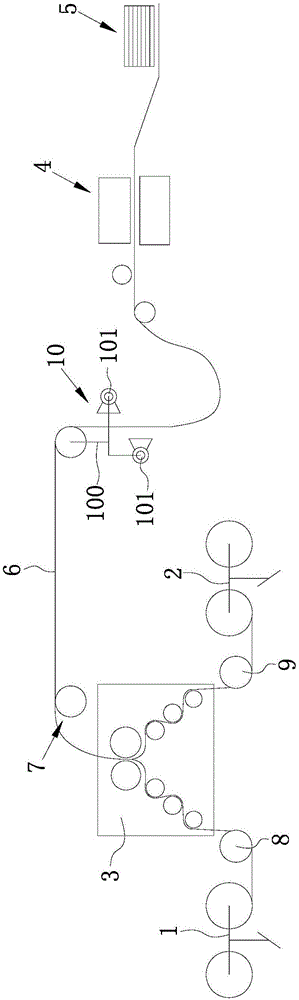

[0023] Such as figure 1 As shown, the production equipment for single-corrugated two-layer cardboard provided by this embodiment includes a first paper rack 1 and a second paper rack 2 for placing two kinds of paper, and a Between the corrugating machine 3, the cutting device 4, the packaging and forming device 5, the delivery device 7 that connects the outlet of the corrugating machine 3 with the inlet of the cutting device 4 to facilitate the transmission of the cardboard 6, is arranged on the first paper frame 1 and the corrugated The first preheating roller 8 between the machine 3, the second preheating roller 9 arranged between the second paper frame 2 and the corrugating machine 3, is used to supply the first preheating roller 8 and the second preheating roller The heat supply unit for heat supply by the roller 9 and the atomized water spray unit 10 near the entrance of the cutting device 4, wherein the particle size of the water mist generated by the atomized water spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com