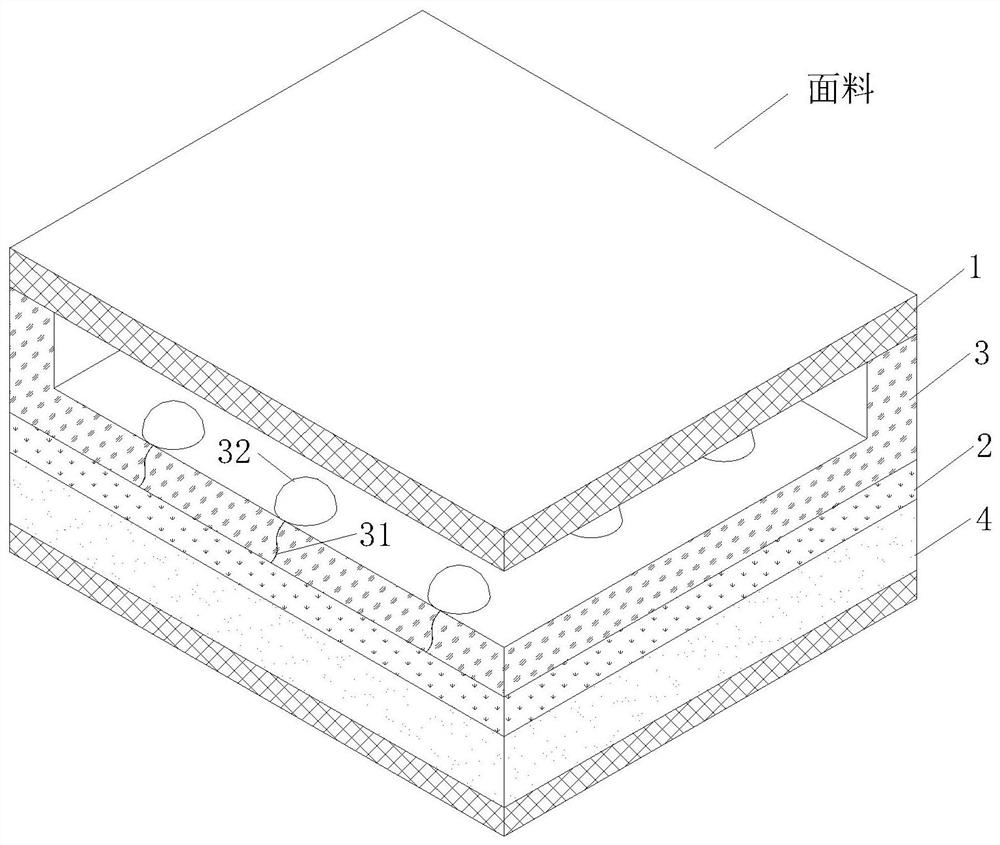

Waterproof, breathable and moisture-permeable green recyclable fabric

A waterproof, breathable, fabric technology, applied in the direction of lamination, lamination auxiliary operation, layered products, etc., can solve the problem of difficult to effectively separate the functional structure of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

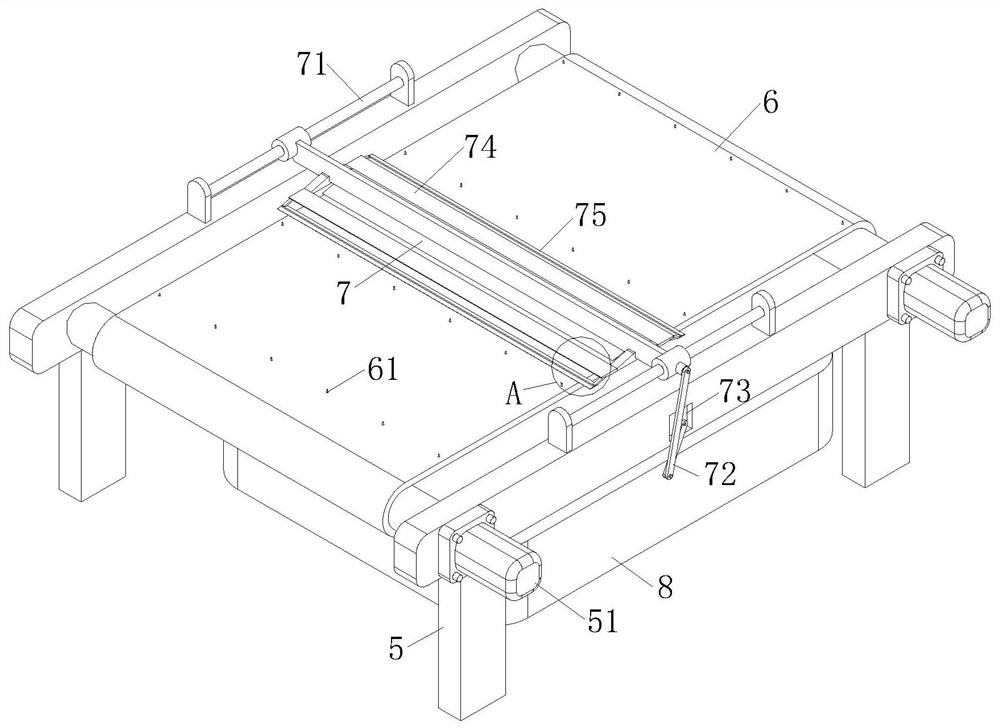

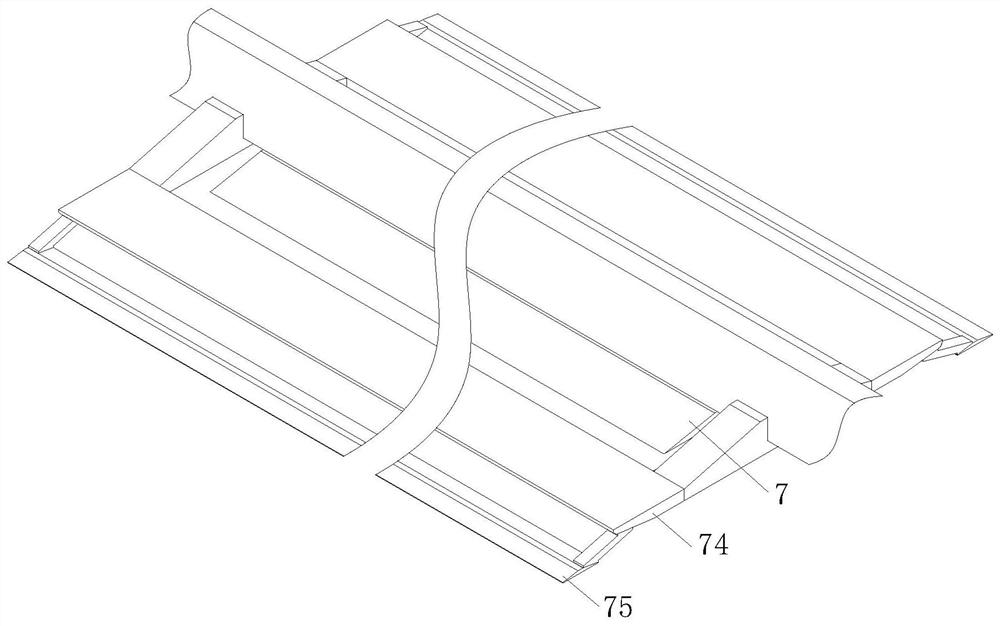

[0023] As an embodiment of the present invention, the sorting equipment includes a body 5, a screen belt 6, a cutting strip 7 and a controller; the body 5 is provided with a screen belt 6, and the end of the body 5 is provided with a drive The motor 51 of screen belt 6 operation; The bottom of described screen belt 6 is provided with steam box 8, and the top of screen belt 6 is provided with cutting strip 7, and the lining of single-pass layer 3 is placed on the screen belt 6, The outside of the fabric faces upward; the controller drives the screen belt 6 to run through the motor 51; the water vapor in the steam box 8 diffuses upward through the screen belt 6; the cut strip 7 is attached to the upper surface of the fabric When the sorting equipment is working, place the one-way layer 3 in the fabric upwards on the screen belt 6, start the controller, and continue to transmit the fabric to be sorted by driving the motor 51, due to the one-way The difference in the structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com