Conductive heating plate pretreatment equipment based on far infrared heating

A processing equipment and far-infrared technology, which is applied in the field of far-infrared heating, can solve the problems of loose joints, loss, and decreased bonding effect of electric heating heating sheets, and achieve the effect of reducing wrinkling and aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

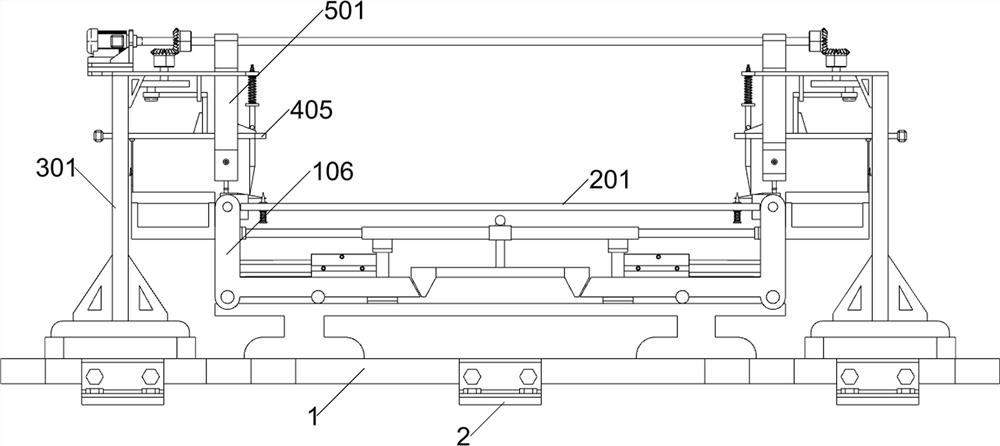

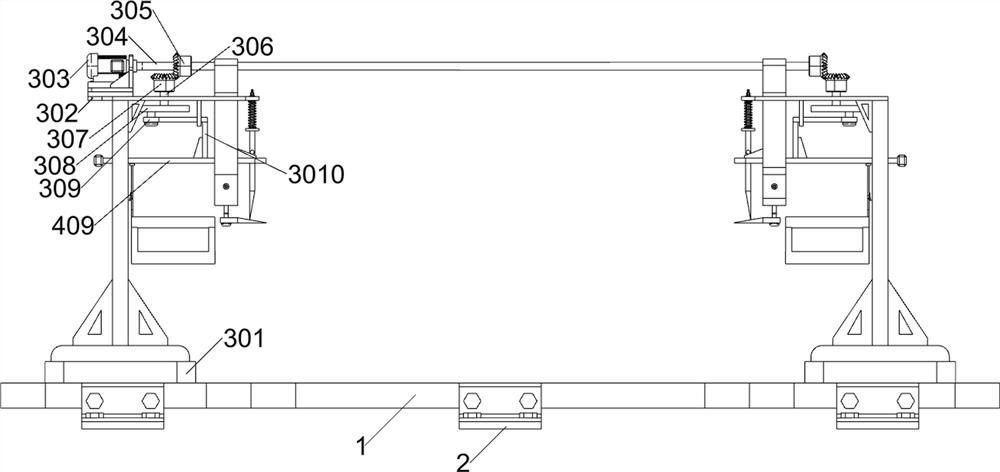

[0037] A pretreatment equipment for conductive heating plate based on far-infrared heating, according to Figure 1-2 As shown, it includes a convex deformation unit, a fixed unit, a power unit, an expansion unit, a glue removal unit, an underframe 1 and an installation buckle 2; the front side and the rear side of the underframe 1 are respectively fixed with three installation buckles 2; The upper surface of the frame 1 is connected with a convex deformation unit; the upper surface of the bottom frame 1 is connected with a power unit; the upper part of the convex deformation unit is connected with a fixed unit; the upper part of the power unit is connected with an expansion unit; the upper part of the power unit is connected with a glue removal unit.

[0038] Before the use of the pre-processing equipment for conductive heating plates based on far-infrared heating, hereinafter referred to as the processing equipment, first install the bottom frame 1 on a stable workbench throug...

Embodiment 2

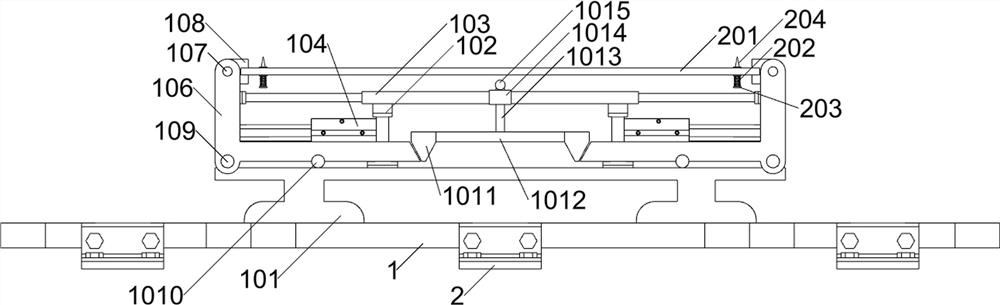

[0040] On the basis of Example 1, according to figure 1 and Figure 3-10 As shown, the convex deformation deformation unit includes a gantry 101, a support plate 102, a telescopic plate 103, a first electric actuator 104, a first connecting rod 105, an L-shaped plate 106, a rotating shaft 107, an electric clamp 108, a first roller Shaft 109, second roller 1010, wedge plate 1011, second connecting rod 1012, first slide bar 1013, connecting block 1014 and ejector rod 1015; the upper surface of bottom frame 1 is bolt-connected with gantry frame 101; the upper surface of gantry frame 101 There are two support plates 102 connected by bolts; an expansion plate 103 is connected by bolts on the upper surfaces of the two support plates 102; a connecting block 1014 is fixedly connected between the two expansion plates 103; There is a first electric actuator 104; each bolt on the opposite side of the telescopic part of the two first electric actuators 104 is connected with a first conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com