Six-gear hybrid transmission for hybrid electric vehicle and application method thereof

A hybrid vehicle and transmission technology, applied in hybrid vehicles, vehicle gearboxes, motor vehicles, etc., can solve the problem of inability to achieve a perfect match of power, economy and comfort, low transmission gear utilization, and gear shifting. There is no power compensation and other problems to achieve the effect of improving driving comfort, reducing fuel consumption and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

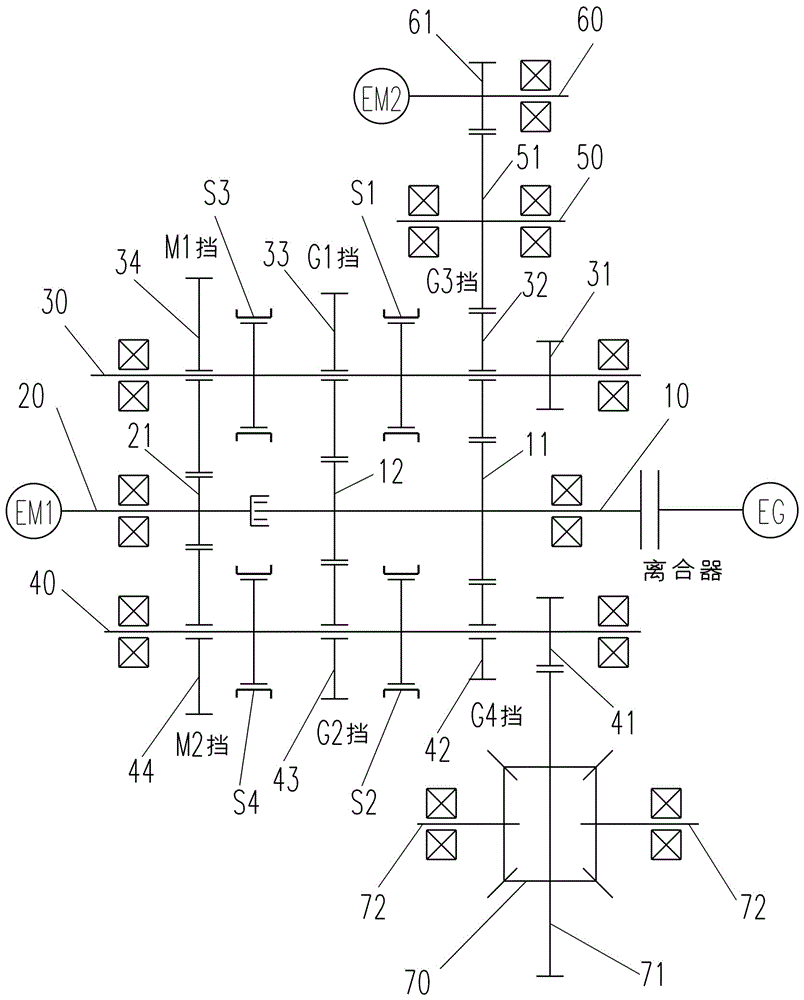

[0032] as attached figure 1 As shown, it is the first mode of arrangement of the motor and the engine of the present invention, the M1 gear is the first gear of the transmission, the M2 gear is the second gear of the transmission, the G1 gear is the third gear of the transmission, the G2 gear is the fourth gear of the transmission, and the G3 gear is the fifth gear of the transmission Gear, G4 gear is the sixth gear of the transmission, the reverse gear is the M1 gear, and the M2 gear is realized by the reverse rotation of the electric motor EM1, and the EM2 is constantly meshed with the G3 gear driven gear through the intermediate wheel.

[0033] No. 1 driving gear 21 is in constant mesh with M1 gear driven gear 34 and M2 gear driven gear 44, No. 2 driving gear 12 is in constant mesh with G1 gear driven gear 33 and G2 gear driven gear 43, and No. 3 driving gear 11 is in constant mesh with G3 gear driven gear 32 and G4 gear driven gear 42 are in constant mesh, intermediate gea...

Embodiment 2

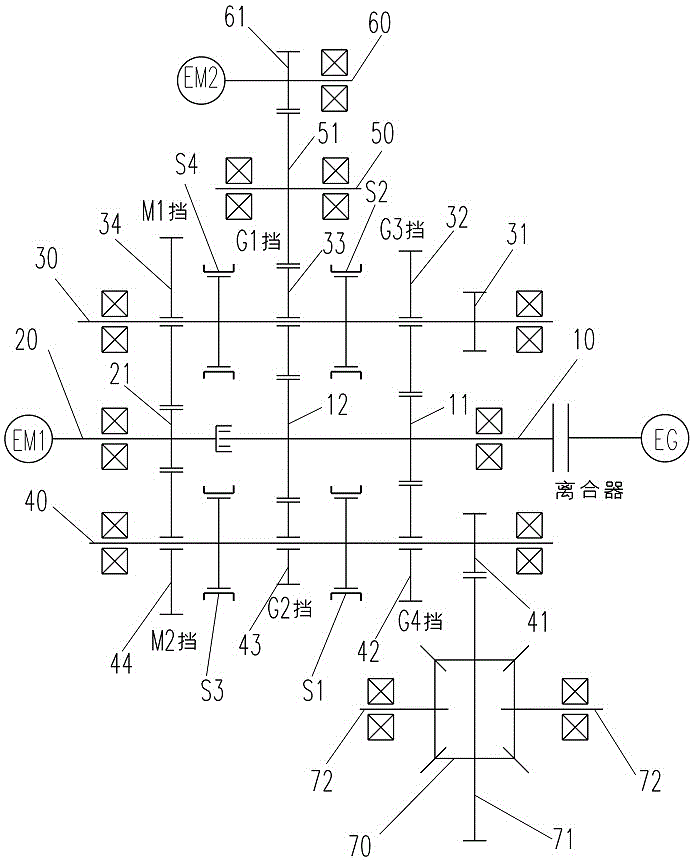

[0046] as attached figure 2 As shown, it is the second mode of arrangement of the motor and the engine of the present invention, the M1 gear is the first gear of the transmission, the M2 gear is the second gear of the transmission, the G1 gear is the fifth gear of the transmission, the G2 gear is the sixth gear of the transmission, and the G3 gear is the third gear of the transmission Gear, G4 gear is the fourth gear of the transmission, the reverse gear is the M1 gear, and the M2 gear is realized by the reverse rotation of the electric motor EM1, and the EM2 is constantly meshed with the G1 gear driven gear through the intermediate wheel.

[0047] No. 1 driving gear 21 is in constant mesh with M1 gear driven gear 34 and M2 gear driven gear 44, No. 2 driving gear 12 is in constant mesh with G1 gear driven gear 33 and G2 gear driven gear 43, and No. 3 driving gear 11 is in constant mesh with G3 gear driven gear 32 and G4 gear driven gear 42 are in constant mesh, intermediate g...

Embodiment 3

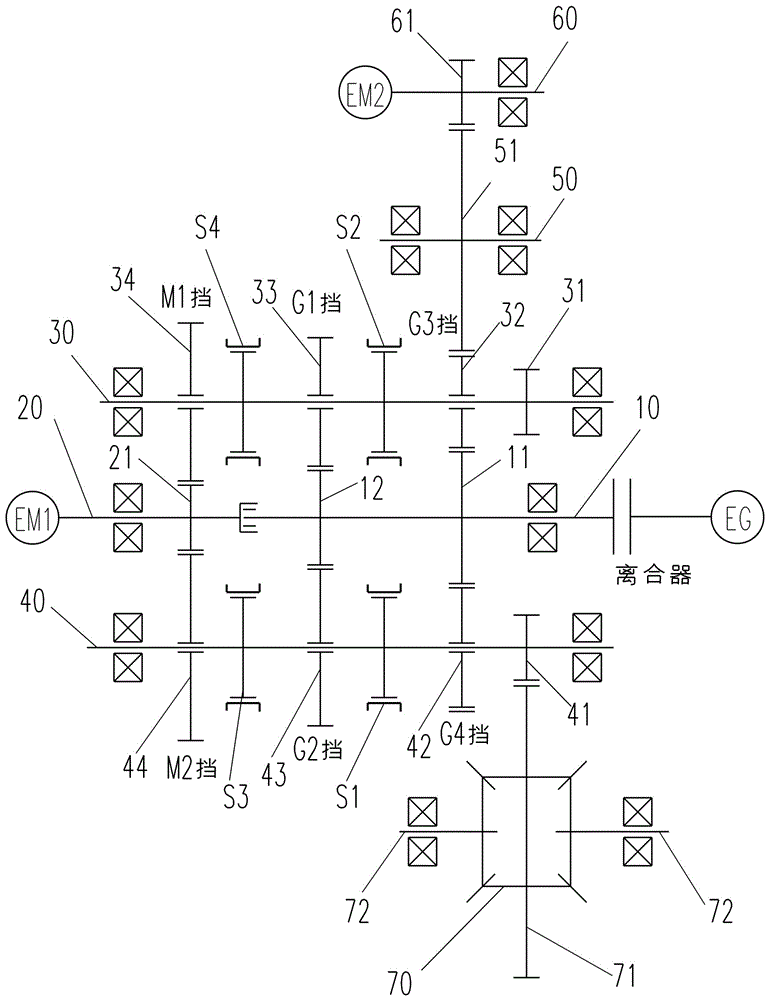

[0060] as attached image 3As shown, it is the third mode of arrangement of the motor and the engine of the present invention, the M1 gear is the second gear of the transmission, the M2 gear is the first gear of the transmission, the G1 gear is the fourth gear of the transmission, the G2 gear is the third gear of the transmission, and the G3 gear is the sixth gear of the transmission Gear, G4 gear is the fifth gear of the transmission, the reverse gear is the M1 gear, and the M2 gear is realized by the reverse rotation of the electric motor EM1, and the EM2 is constantly meshed with the G3 gear driven gear through the intermediate wheel.

[0061] No. 1 driving gear 21 is in constant mesh with M1 gear driven gear 34 and M2 gear driven gear 44, No. 2 driving gear 12 is in constant mesh with G1 gear driven gear 33 and G2 gear driven gear 43, and No. 3 driving gear 11 is in constant mesh with G3 gear driven gear 32 and G4 gear driven gear 42 are in constant mesh, intermediate gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com