Waterproof material packing device

A waterproof material and assembly frame technology, which is applied in the direction of packaging, transportation and packaging, and delivery of filamentous materials, etc., can solve problems affecting the production continuity of waterproof materials, heating uniformity, and lower production efficiency, so as to achieve uniform heating , Improve work efficiency and ensure the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiment of this waterproof material packing device is described in detail below in conjunction with accompanying drawing:

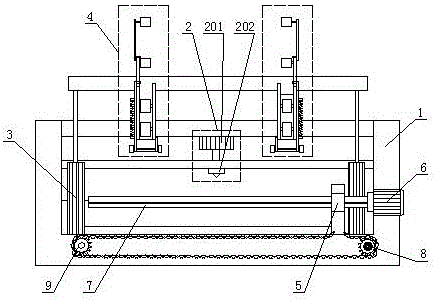

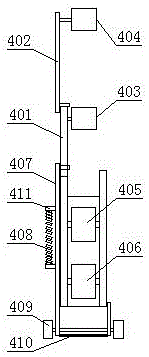

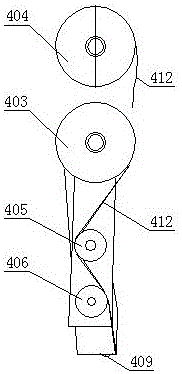

[0016] The waterproof material packaging device is composed of a frame 1, a cutting and blanking assembly 2, a packaging assembly 4, and a transmission jacking servo mechanism. The transmission jacking servo mechanism includes a servo motor 6, a jacking cylinder 3, a transmission motor, a jacking cylinder, and an electric motor. The middle part of the frame 1 is hoisted with a cutting and blanking assembly 2; the frame 1 is symmetrically installed with a packing assembly 4 through the jacking cylinder 3, and the frame 1 below the packing assembly 4 is equipped with a push slide plate 5 through a guide rail, and the push slide plate 5 below A motor is installed in the frame 1, a servo motor 6 is installed on the frame 1 on one side of the pushing slide plate 5, and a winding tube 7 is installed on the output end of the servo motor 6, and the w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap