Production method of composite railway transportation lined packaging bag provided with air bags

A technology of railway transportation and production method, applied in the field of packaging materials, can solve the problems of airtight sealing of inner bags, affecting feeding speed and efficiency, and poor moisture-proof sealing performance of single-layer bag body structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

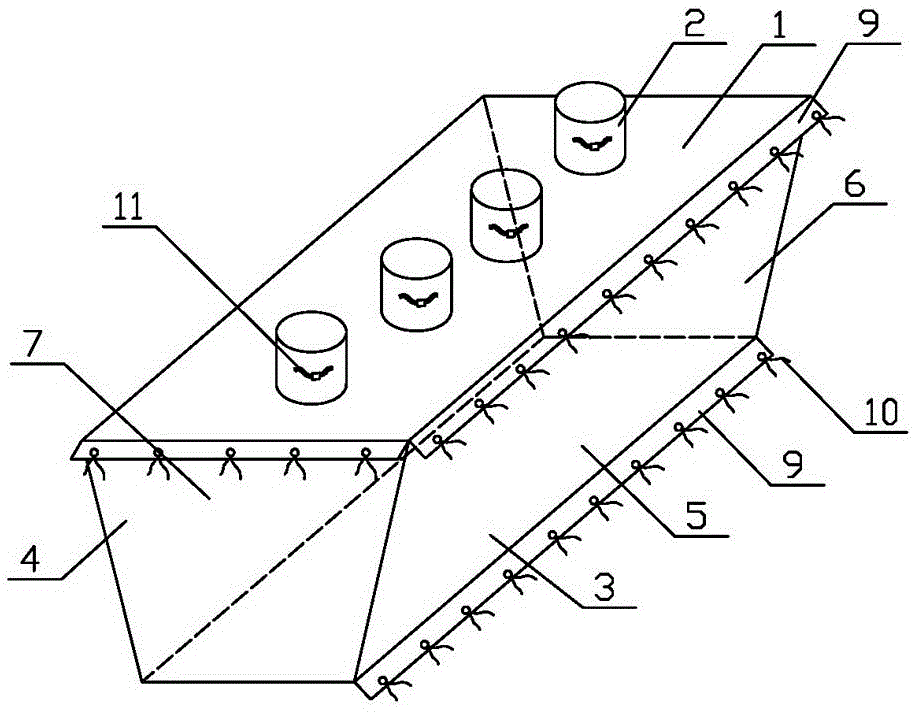

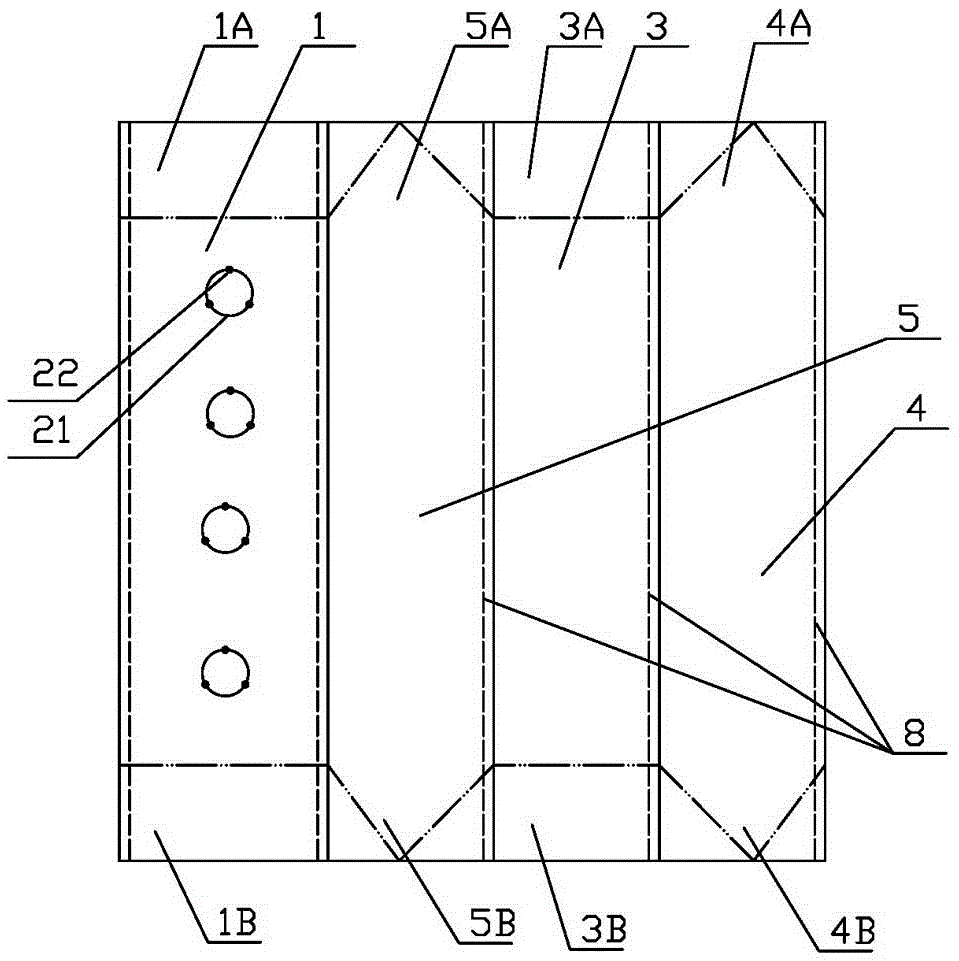

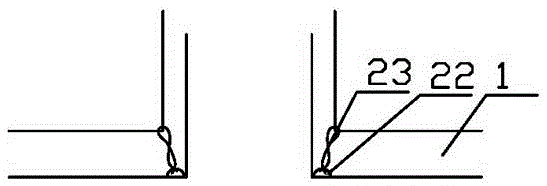

[0020] Such as figure 1 As shown, the composite railway transport liner packaging bag with buffer airbag of the present invention includes a bag body 1 with a feed pipe 2, and the bag body 1 is composed of an upper sheet 1 and a lower sheet 3 with a rectangular structure. , the left sheet 4, and the right sheet 5 are sequentially connected to form a cylindrical body and a front sheet 6 and a rear sheet 7 arranged at both ends of the cylindrical body. A circular mounting hole 21, the lower end of the feed pipe 2 is connected in the mounting hole 21; the two sides of the front sheet 6 and the front ends of the left sheet 4 and the right sheet 5 respectively pass through triangular The front airbag 61 is connected; the two sides of the rear sheet 7 are connected with the rear ends of the left sheet 4 and the right sheet 5 respectively through triangular rear airbags 71, 72; the front airbag 61 and the rear airbag 71, 72 communicate with the inner cavity of the bag body 1 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com