Easy release glass forming mold

A glass forming and easy demoulding technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of difficult to take out, affect the glass demoulding work, and difficult to disassemble the mold, so as to achieve easy disassembly and speed up glass forming. Speed, Cooldown Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

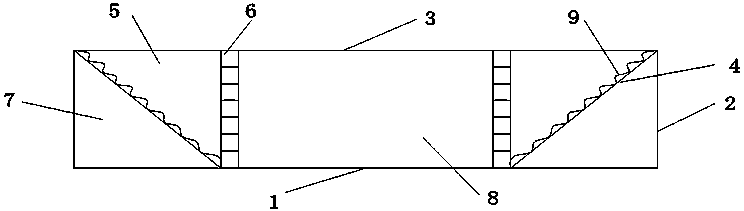

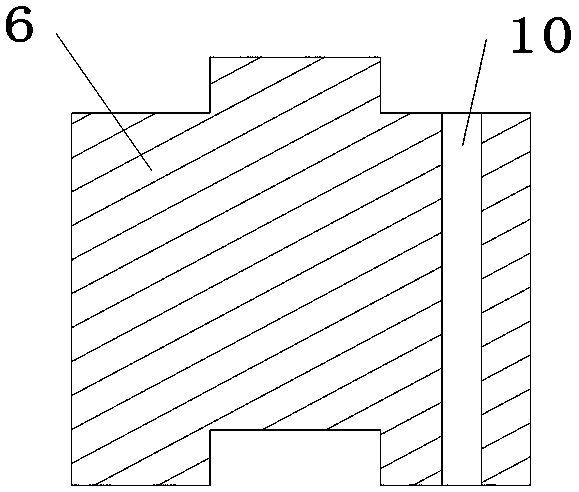

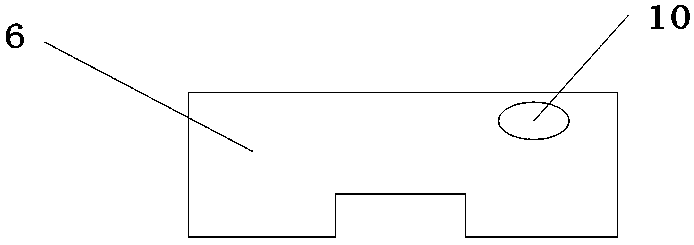

[0016] The reference signs in the drawings of the description include: bottom mold 1, support plate 2, upper mold 3, support rod 4, conical ice table 5, ceramic sheet 6, water storage chamber 7, glass forming chamber 8, protrusion 9, Through hole 10.

[0017] The embodiment is basically as attached figure 1 Shown: a glass molding mold that is easy to demould, including a bottom mold 1 and an upper mold 3, the bottom mold 1 is surrounded by a support plate 2 perpendicular to the bottom mold 1, the upper mold 3 is placed on the support plate 2, and the bottom mold 1. A conical cavity is arranged coaxially at the upper center. The conical cavity is located inside the support plate 2. The conical cavity is formed by a number of support rods 4 arranged at intervals. The angle formed between the support rods 4 and the bottom mold 1 is 45°. The support rods 4 There are several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com