A Vibration Aging Treatment Method for Large Metal Components of Rail Transit Equipment

A metal component, vibration aging technology, applied in the field of rail transit equipment testing, to achieve the effects of strong operability, elimination of residual stress, and high elimination of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

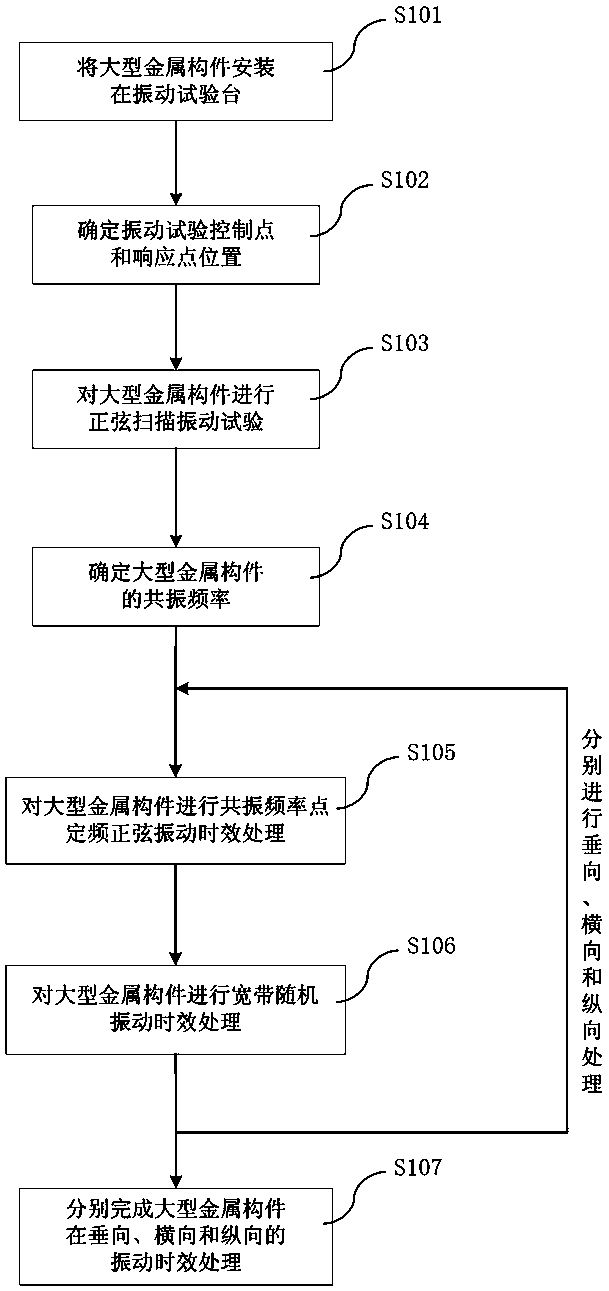

[0065] as attached figure 1 As shown, a specific embodiment of a vibration aging treatment method for large metal components of rail transit equipment, comprising the following steps:

[0066] S101: installing the large metal component 1 on the vibration test bench 3;

[0067] S102: Determine the location of the vibration test control point and response point;

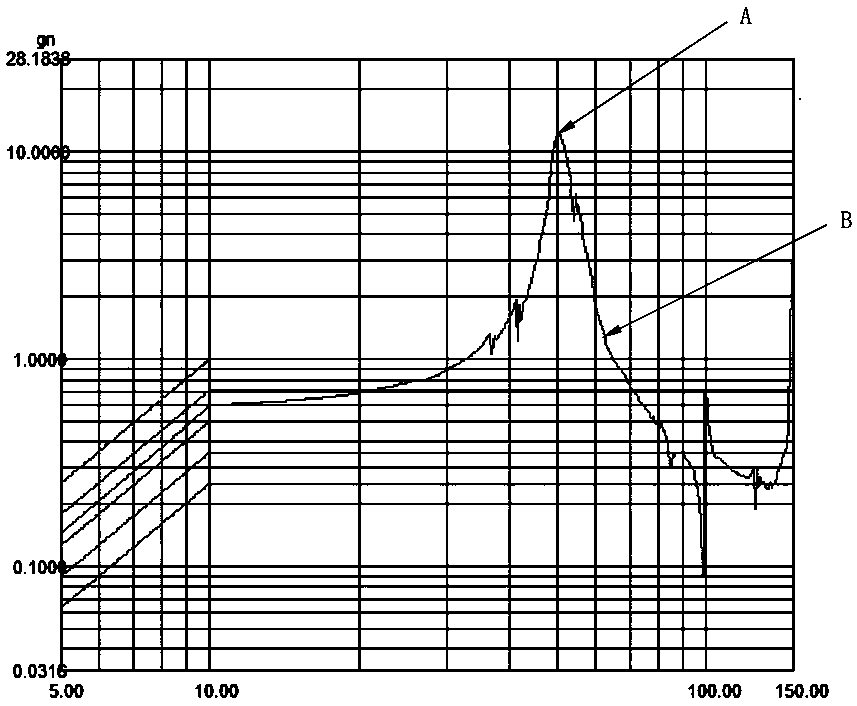

[0068] S103: Conduct a sinusoidal scanning vibration test on the large metal component 1;

[0069] S104: determining the resonance frequency of the large metal component 1;

[0070] S105: Perform aging treatment of fixed-frequency sinusoidal vibration at the resonance frequency point for the large metal component 1;

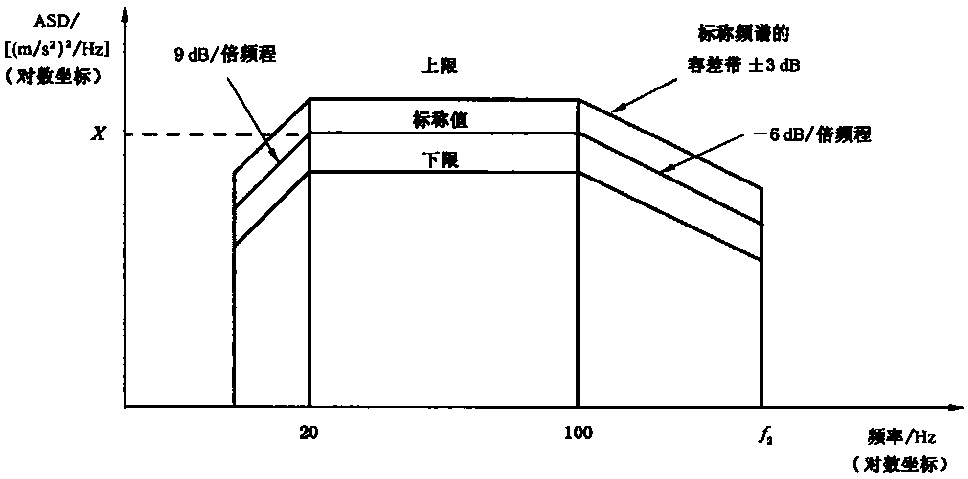

[0071] S106: performing broadband random vibration aging treatment on the large metal component 1;

[0072] S107: Repeat the above steps S102 to S106 to respectively complete the vibration aging treatment of the large metal component 1 in the vertical, horizontal and longitudinal directions.

[0073]...

Embodiment 2

[0095] Another specific embodiment of the vibration aging treatment method for large metal components of rail transit equipment, including the following steps:

[0096] S101: installing the large metal component 1 on the vibration test bench 3;

[0097] S102: Determine the location of the vibration test control point and response point;

[0098] S103: Conduct a sinusoidal scanning vibration test on the large metal component 1;

[0099] S104: determining the resonance frequency of the large metal component 1;

[0100] S105: performing broadband random vibration aging treatment on the large metal component 1;

[0101] S106: Perform aging treatment of fixed-frequency sinusoidal vibration at the resonance frequency point on the large metal component 1;

[0102] S107: Repeat the above steps S102 to S106 to respectively complete the vibration aging treatment of the large metal component 1 in the vertical, horizontal and longitudinal directions.

[0103] Embodiment 2 On the basis...

Embodiment 3

[0105] Embodiment 3 On the basis of the foregoing embodiments 1 and 2, the vibration aging treatment of the large metal member 1 is completed in the order of vertical → horizontal → longitudinal vibration directions, which is the preferred sequence of vibration directions in the present invention. Of course, it is also possible to change the order of vibration directions of large metal components to achieve similar effects, such as vertical → vertical → horizontal and so on.

[0106] By implementing the technical scheme of the vibration aging treatment method for large metal components of rail transit equipment described in specific embodiments of the present invention, the following technical effects can be produced:

[0107] (1) The vibration aging treatment method for large metal components of rail transit equipment described in the specific embodiments of the present invention is simple, reliable, and highly operable, and can quickly and effectively eliminate the residual s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com