Heat recovering fresh air machine

A new fan and heat recovery technology, applied in heat recovery systems, space heating and ventilation, space heating and ventilation details, etc., can solve problems such as non-recycling, reduced energy return efficiency, and inability to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical features and functions of the present invention in detail and realize them according to the content of this specification, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

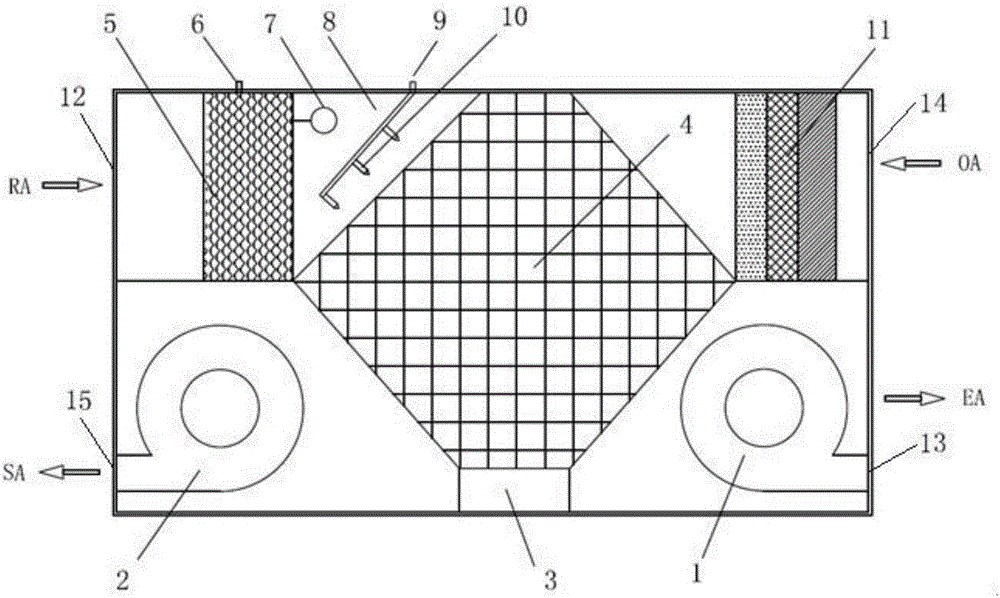

[0023] figure 1 It schematically shows an embodiment of a heat recovery fresh air blower among numerous embodiments of the present invention, figure 1 Among them, OA indicates outdoor air intake, EA indicates outdoor exhaust air, RA indicates indoor return air, SA indicates indoor fresh air, and arrows indicate the flow direction of return air or fresh air. The heat recovery fresh air machine includes exhaust fan 1, air supply fan 2, power distribution box 3, heat exchange core 4, wet film 5, drain hole 6, condensate pump 7, condensate pan 8, water inlet pipe 9, water Mist nozzle 10, filter material 11, return air inlet 12, exhaust air outlet 13, fresh air inlet 14, air supply outlet 15, ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com