Swing flash drying device for spinning

A fast drying and fast technology, which is applied in the drying field to achieve the effects of improving drying efficiency, high drying efficiency and expanding contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

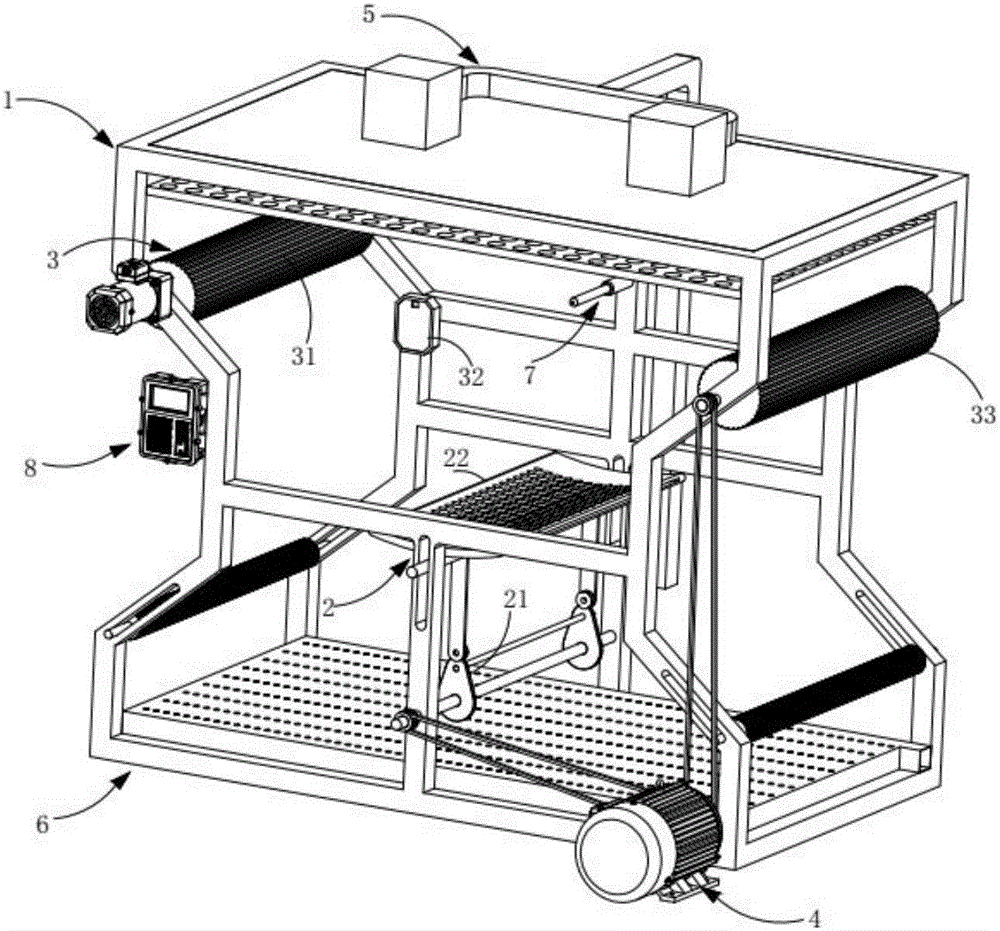

[0031] Such as figure 1 Shown, a kind of swing fast drying device for weaving, comprising:

[0032] Box 1; and

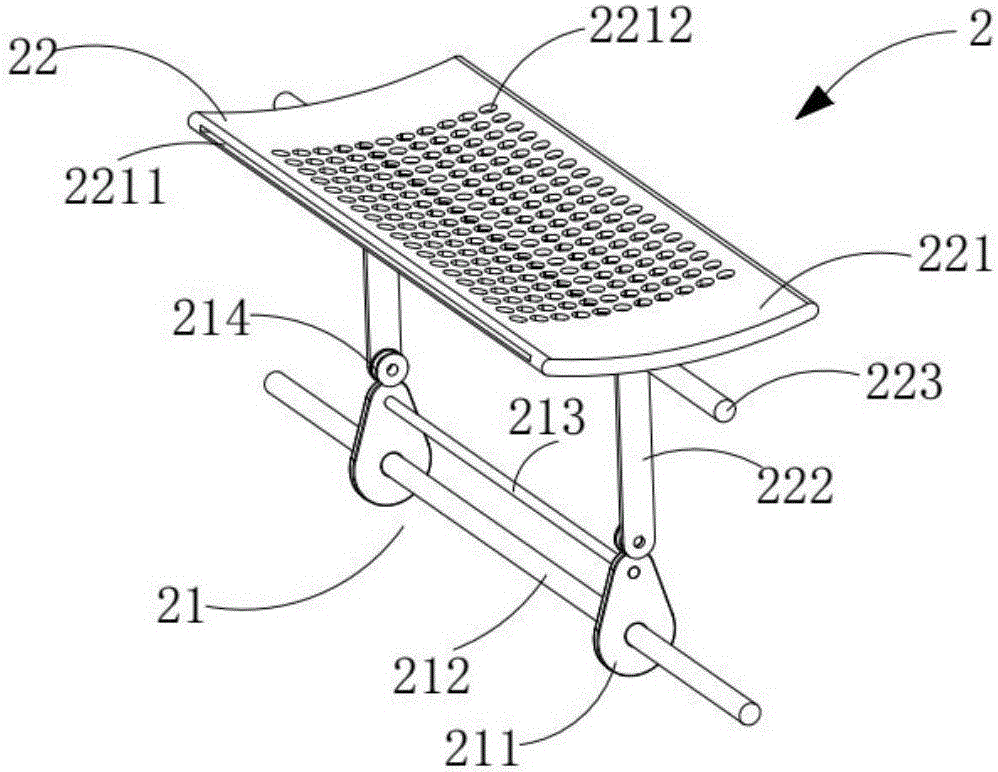

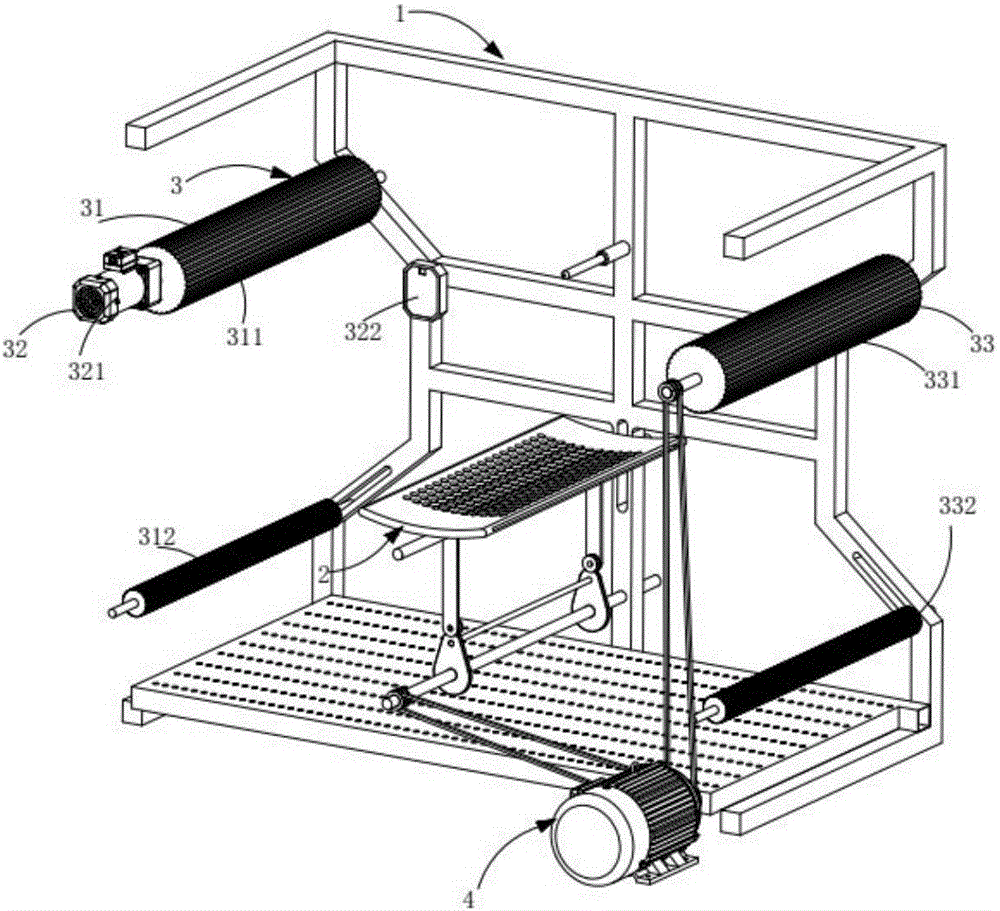

[0033] A swinging quick-drying mechanism 2, the swinging quick-drying mechanism 2 is arranged in the middle of the box body 1, including a swinging assembly 21 and a quick-drying mechanism 22, and the swinging assembly 21 drives the quick-drying mechanism 21 to reciprocate up and down;

[0034] Conveying mechanism 3, said conveying mechanism 3 is horizontally arranged on box body 1, includes input assembly 31 and intermittent drive assembly 32 arranged at the front end of said swinging quick-drying mechanism 2, and output arranged at the rear end of said swinging quick-drying mechanism 2 Component 33;

[0035] A driving mechanism 4, the driving mechanism 4 is connected to the swing assembly 21 through belt transmission, and drives the swing assembly 21 to move.

[0036] It should be noted that during the process of the quick-drying mechanism 22 reciprocating up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com