A Method for Generating Full-scale Wiring Harness Tooling Board Drawing Based on CAD Platform

A wire harness tooling board, full-scale technology, applied in the direction of configuration CAD, CAD circuit design, instruments, etc., can solve the problems of efficiency and accuracy decline, low efficiency, error-prone, etc., to achieve rapid generation and production, clear position, Avoid the wrong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0046] A kind of generation method of the full-size wiring harness tooling board diagram based on the CAD platform of the present invention adopts the ARX development environment of the C++ language supported by the CAD platform, edits various command modules, and performs the following operation steps in conjunction with the original commands of the CAD platform; this preferred example , AutoCAD is used as the CAD platform for illustration.

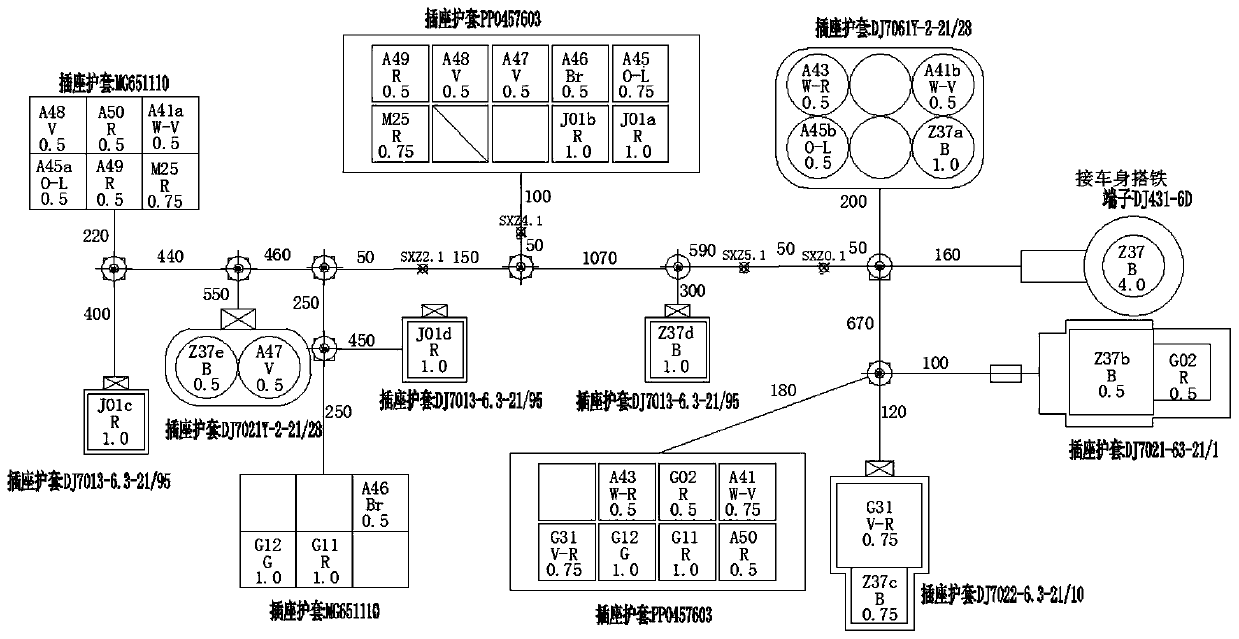

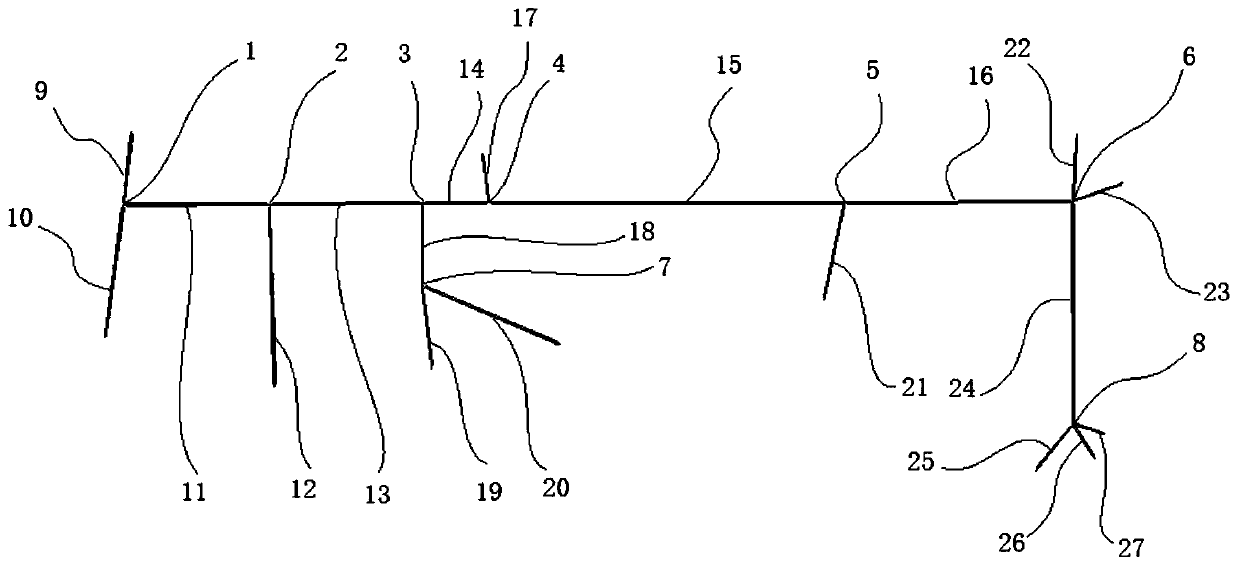

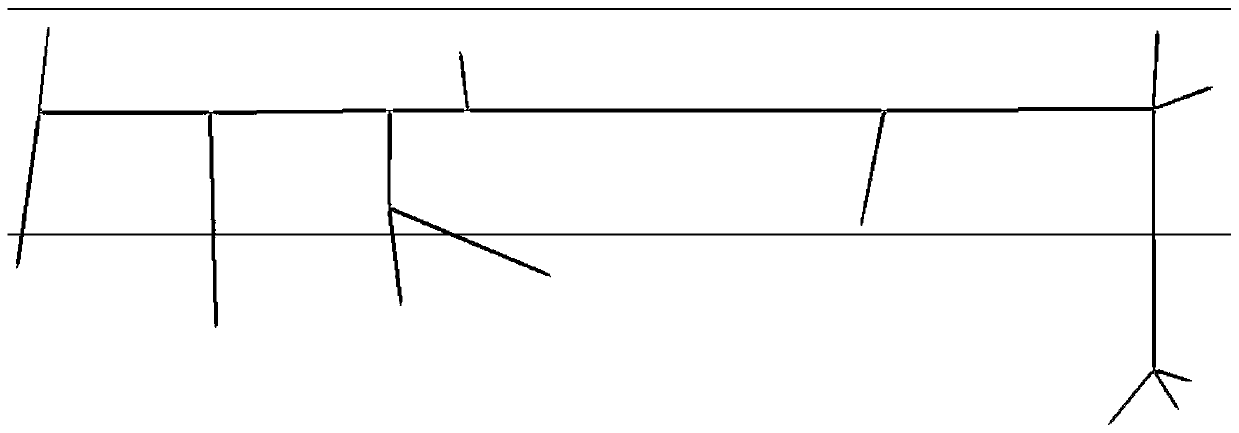

[0047] Step 1, the wire length parameters, node parameters, connector parameters and connector corresponding wire end parameters recorded in the wire harness diagram corresponding to the full-size wire harness tooling board are formed into a tree-structured CAD attribute block to obtain the target wire harness diagram before conversion, Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com