Wire saw used for landscape engineering lumbering

A technology of engineering and wire sawing, which is applied in the field of wire sawing in gardening engineering logging, and can solve the problems of trees with different hardness, saw blades without automatic adjustment, and saw teeth that cannot cut wood quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

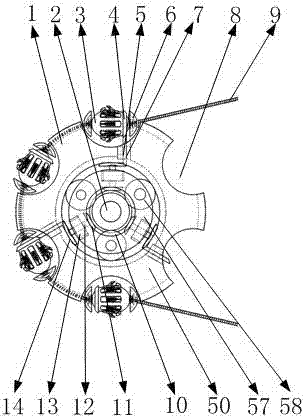

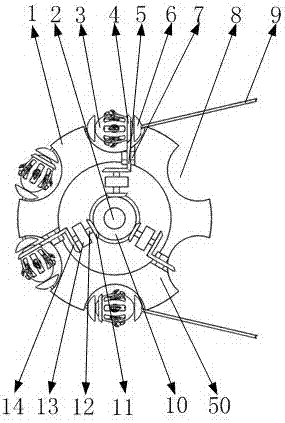

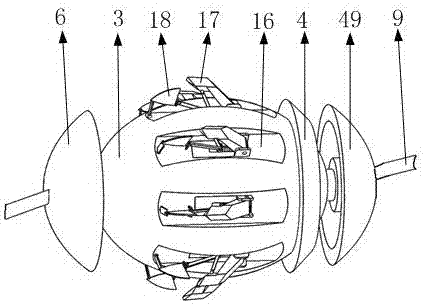

[0041] In a specific embodiment, when the wire saw is not in use, the spring 37 is in a state of free expansion and contraction. When working, the transmission shaft 2 rotates, the driving spur gear 15 installed on the transmission shaft 2 rotates, and the internal teeth 25 drive the driving wheel 1 to rotate. At the same time, the third bevel gear 10 installed on the transmission shaft 2 will sequentially drive the fourth bevel gear 11, the fifth bevel gear, the second bevel gear 5, and the first bevel gear 4 to rotate, driven by the first bevel gear 4 , the sawtooth unit 49 installed on the wire rope 9 will rotate around its own axis. At this time, the sawtooth unit 49 moves under the drive of the drive wheel 1 and rotates around the flexible shaft 20. The two movements work together to achieve the effect of cutting wood quickly. When running into harder wood, the induction sheet 18 cannot cut into the wood as normal, and the force received by the induction sheet 18 will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com