Polyol composition for rigid polyurethane foam, and method for producing rigid polyurethane foam

A technology of polyol composition and rigid polyurethane, which is applied in the field of polyol composition for rigid polyurethane foam and rigid polyurethane foam, can solve the problems of large global warming coefficient, etc., and achieve the purpose of suppressing the decline of physical properties, Good storage stability of stock solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8、 comparative example 1~6

[0076] [Preparation of polyol composition]

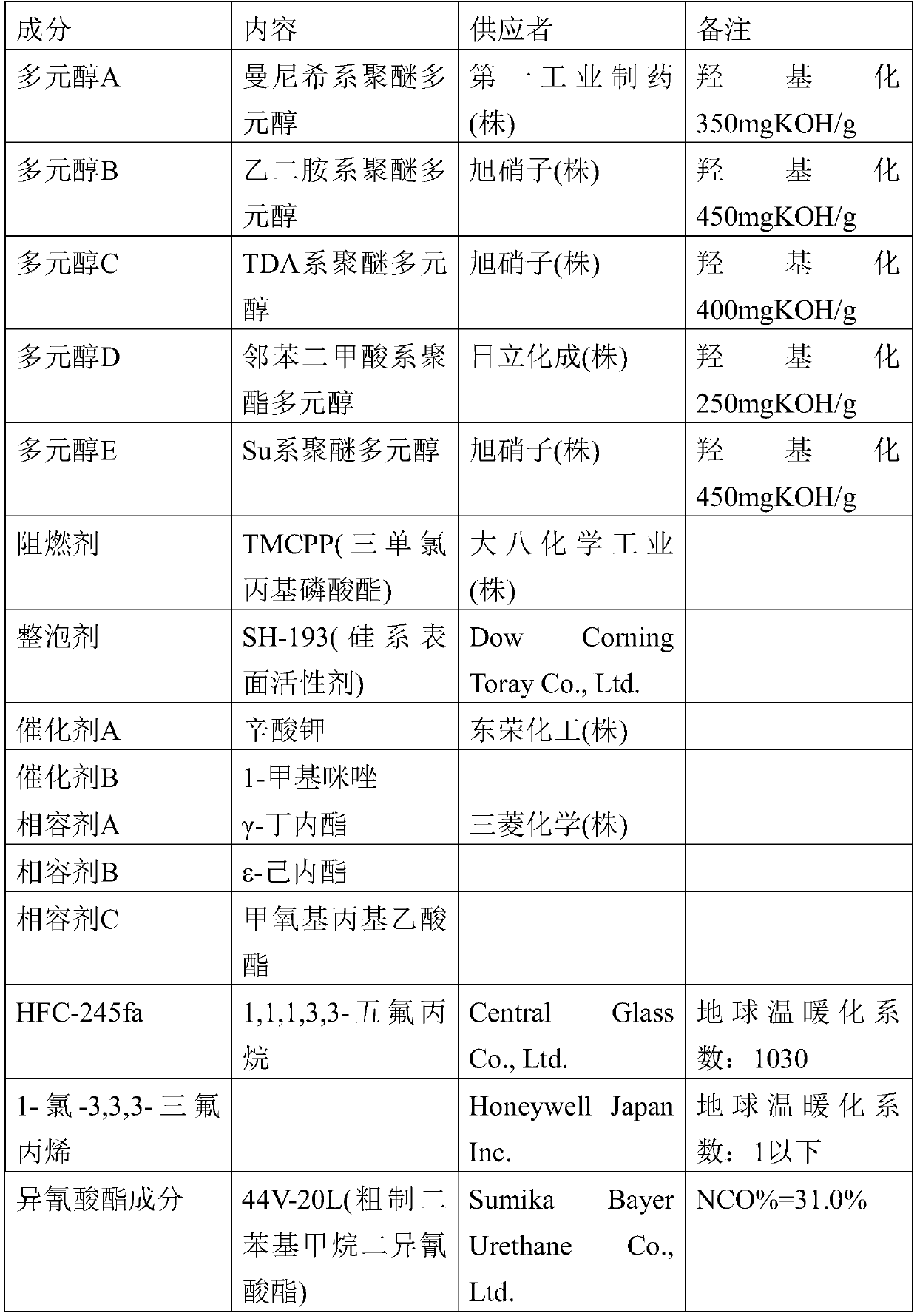

[0077] The constituent materials of the polyol composition are shown in Table 1.

[0078] [Table 1]

[0079]

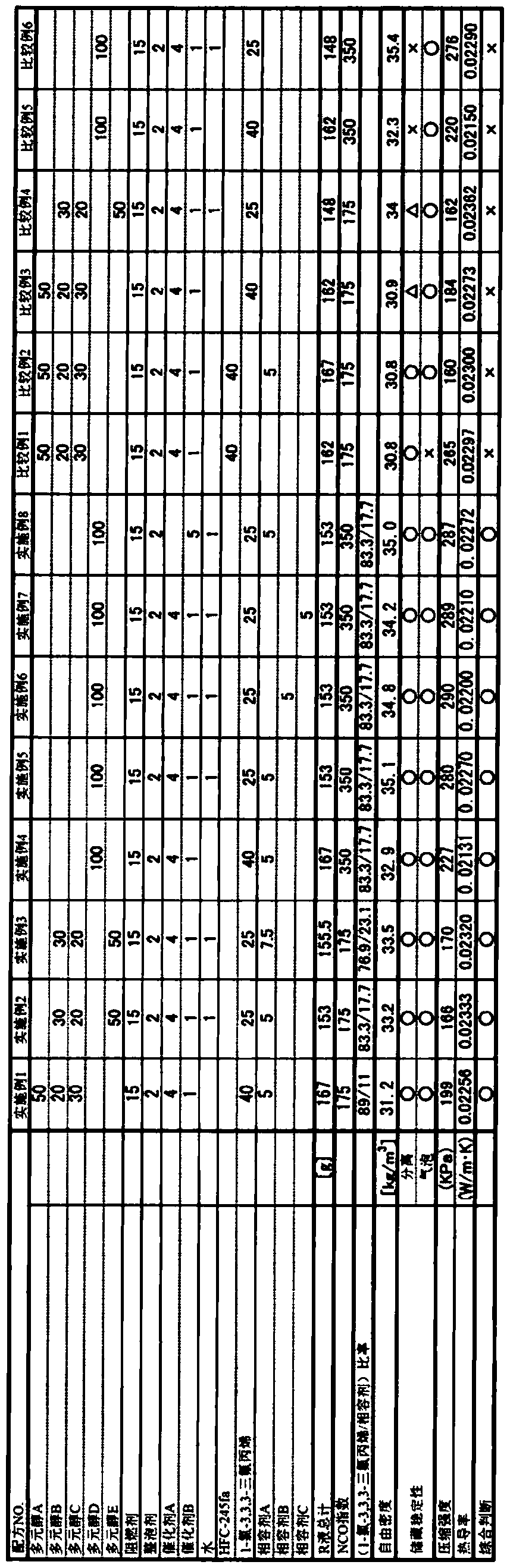

[0080] The constituent materials shown in Table 1 were mixed and stirred with the formulation described in Table 2 below, and the polyol compositions of Examples 1-8 and Comparative Examples 1-6 were prepared.

[0081] 〔Manufacture of rigid polyurethane foam〕

[0082] The temperature of the polyol composition of Examples 1 to 8 and Comparative Examples 1 to 6 was adjusted to 20°C, and then, the temperature was adjusted to 20°C with the isocyanate component (crude diphenylmethane produced by Sumika Bayer Urethane Co., Ltd. Diisocyanate "Sumidur 44V-20L", NCO%: 31%) was mixed with a laboratory mixer at a ratio of NCO / OH equivalent ratio of 175 or 350, and foamed and solidified to obtain a rigid polyurethane foam. Table 2 shows the evaluation results of the rigid polyurethane foam.

[0083] [Table 2]

[0084]

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com