High-efficient tea winnowing machine convenient to adjust

An air separator and high-efficiency technology, which is applied in the directions of pre-extraction tea treatment, chemical instruments and methods, solid separation, etc., can solve problems such as difficulty in grasping the impact force and drop of tea leaves, influence, unclear classification, etc., to promote efficient separation, The effect of preventing clogging and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

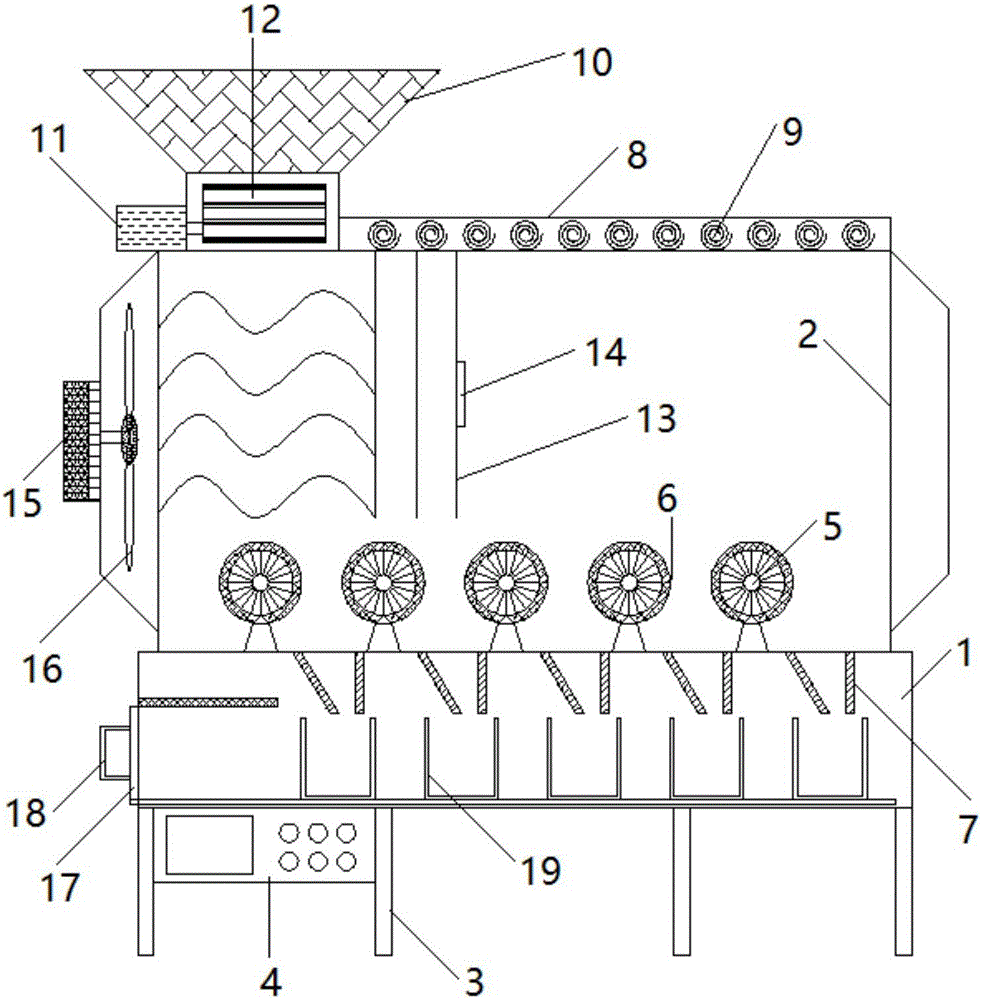

[0018] The tea leaves enter the winnowing drum 2 from the feed port 10, and the feed polarizer 12 is arranged under the feed port 10, and cooperates with the screen 13, which can not only shake the tea leaves, promote the efficient separation of impurities, but also prevent the feed port 10 from being blocked. The main fan 16 rotates at a high speed under the action of the driving motor 15, and blows the tea leaves to the other end. When the tea leaves touch the screen 13, impurities fall under the action of gravity, and the tea leaves slowly fall under the joint action of wind force and gravity On the rotating wheel 5, the rotating wheel 5 cooperates with the electric heating wire mesh 6, the tea leaves slide off from the rotating wheel 5, the impact is reduced, and the humidity of the tea leaves is controlled by heating. The tea leaves fall farther, and the tea leaves fall into the tea collection box 19 on the push-pull drawer 17 through the discharge port 7, which is conduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com