High-efficiency deslagging device and high-efficiency deslagging system

A high-efficiency and equipment technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of eutrophication of water bodies, pollution of receiving water bodies, adverse effects on life, etc., to reduce investment costs, improve the environment, and improve The effect of sewage removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

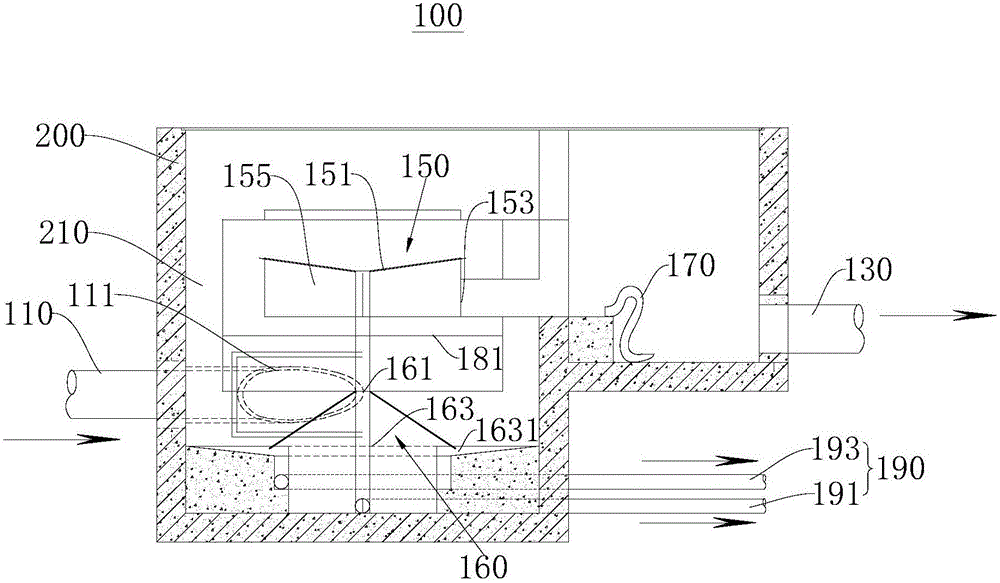

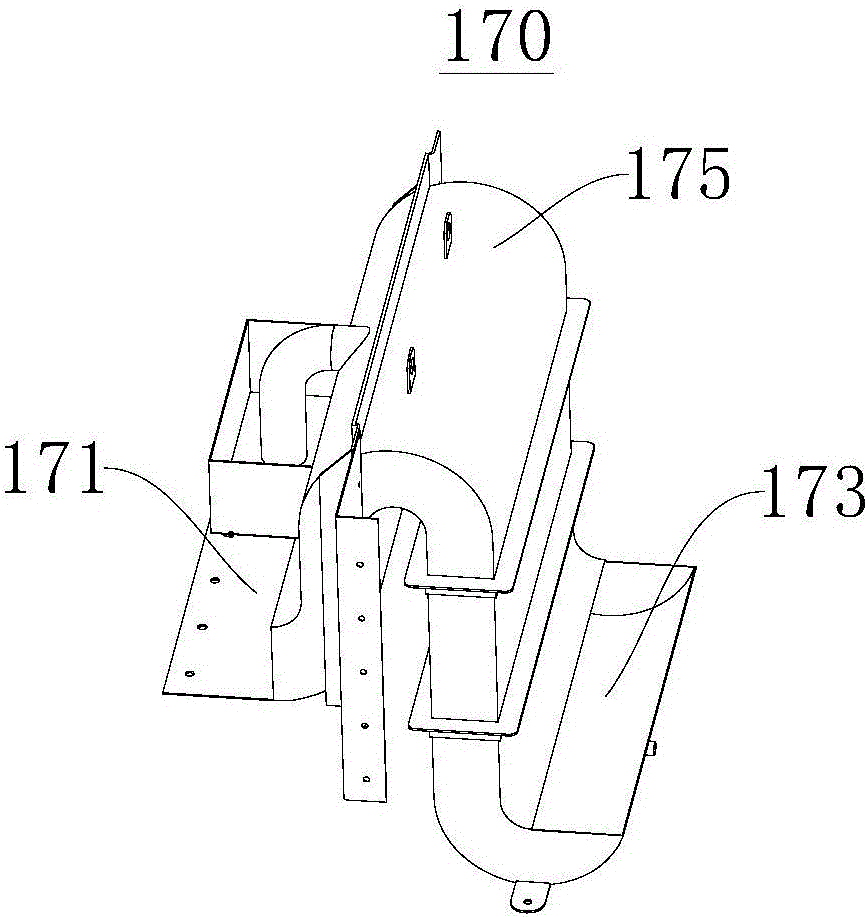

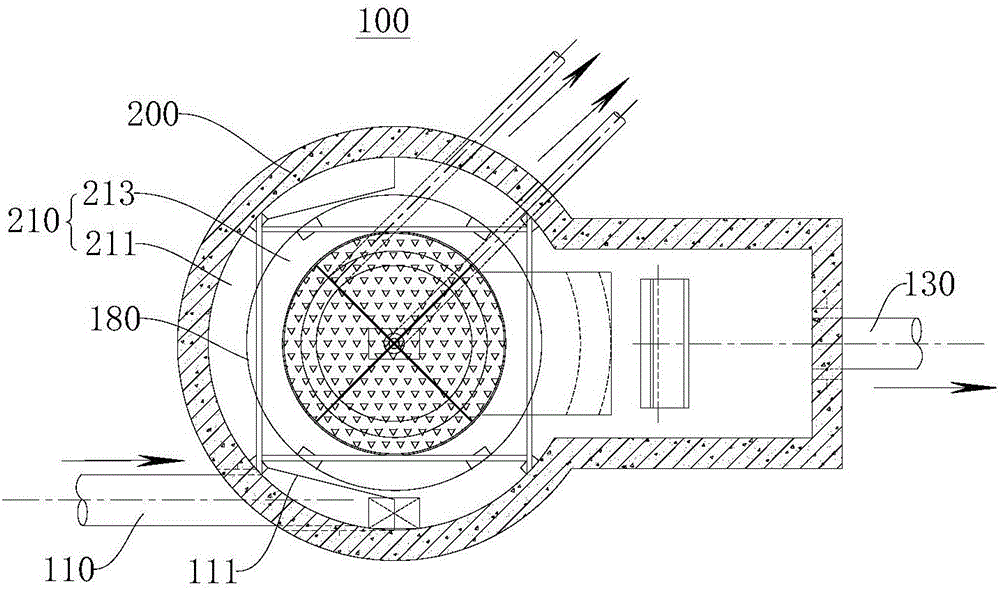

[0032] figure 1It is a structural schematic diagram of the first viewing angle of the high-efficiency slag removal equipment 100 provided by the first embodiment of the present invention. The high-efficiency slag removal equipment 100 provided in this embodiment is mainly used in sewage discharge; especially in the rainwater combined discharge system in cities, it can filter and remove slag from the rainwater overflow situation in stormy weather, and can simultaneously clean the water in the equipment. The filter assembly 150 is repeatedly backwashed to achieve the self-cleaning function, and collects and treats the pollutants in the sewage to avoid polluting the downstream water body, thereby improving the surrounding environment. In this embodiment, the description is made using the situation of rainwater overflow in rainstorm weather.

[0033] see figure 1 The high-efficiency slag removal equipment 100 provided by the first embodiment of the present invention is mainly us...

no. 2 example

[0052] Figure 4 It is a schematic structural diagram of a high-efficiency slag removal system 300 provided in the second embodiment of the present invention. see Figure 4 , the high-efficiency slag removal system 300 provided in this embodiment includes the high-efficiency slag removal equipment 100 provided in the first embodiment. The high-efficiency slag removal equipment 100 provided in this embodiment has the same basic structure and working principle as that of the first embodiment. For brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0053] In this embodiment, the high-efficiency slag removal system 300 includes high-efficiency slag removal equipment 100, a confluence pipe 310, a water inlet well 330, and a sewage well 350. The confluence pipe 310 is connected and communicated with the sewage assembly 190 .

[0054] The high-efficiency slag removal system 300 provided by thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com