Desulfurizing tower-silo structure

A desulfurization tower and cylinder technology, which is applied in the field of improvement of the structure of the desulfurization tower, can solve the problems of reduced safety factor, damage, and easy corrosion of the desulfurization tower, and achieves the effects of improving the service life, being convenient to use, and being easy to replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

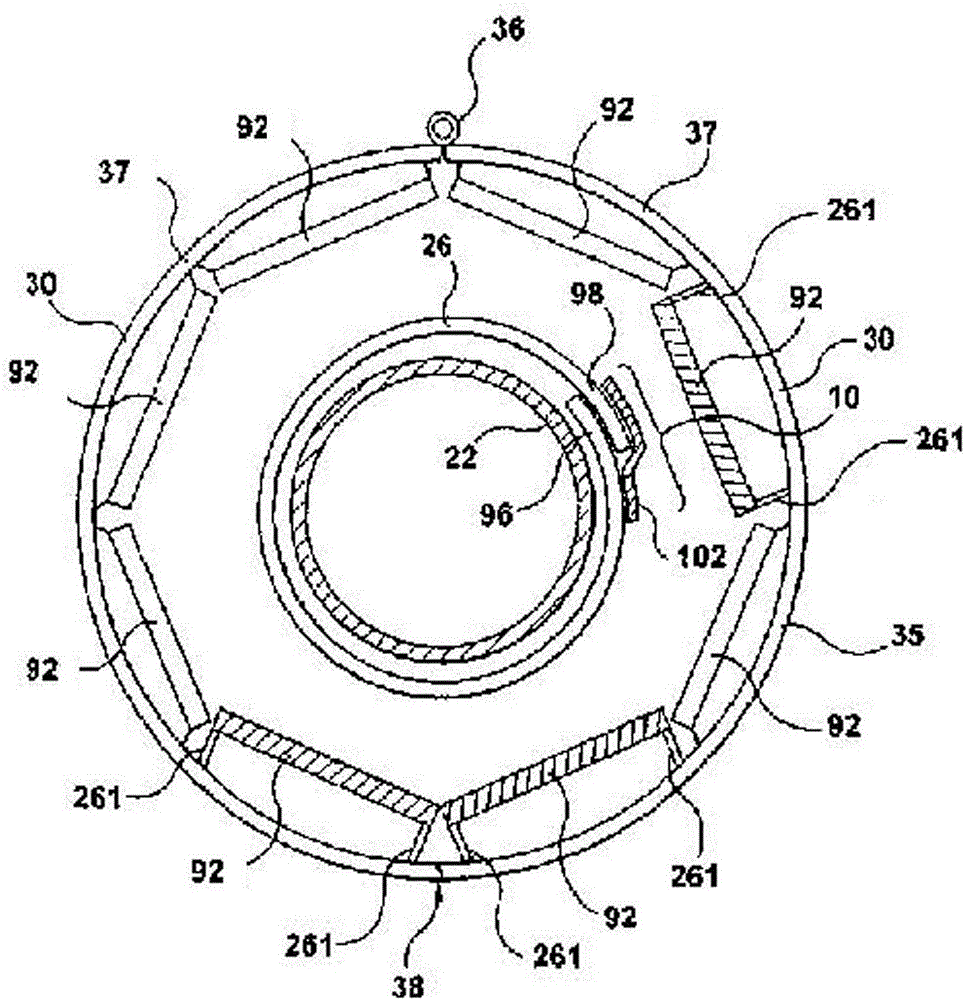

[0017] The desulfurization tower structure of the present invention includes a compensation part 10, a support cylinder 22, a sheath 26, an outer wall 30, a cylinder body 35, a climbing device 36, an inner wall 37, a cylinder body 38, a desulfurizing agent spray washing device 92, and an inner layer part 96. The lamination part 98, the buckle 102 and the support arm 261 are characterized in that: the inner wall 37 of the cylinder body 35 of the cylinder 38 is provided with a desulfurizer spray washing device 92 through the support arm 261; There is a support cylinder 22; a sheath 26 is provided outside the support cylinder 22, and a corresponding lamination part 98 and an inner layer part 96 are provided at the end of the sheath 26; the lamination part 98 and the inner layer part 96 constitute the compensation part 10; A buckle 102 is arranged on the outside of the compensation part 10 .

[0018] As a preferred solution of the present invention, a climbing device 36 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com