T-shaped iron core press-in device for motor coil assembling machine

A press-in device and coil set technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of unguaranteed assembly accuracy, low work efficiency, accuracy dependence, etc., and achieve low cost and volume occupation. Large land area and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

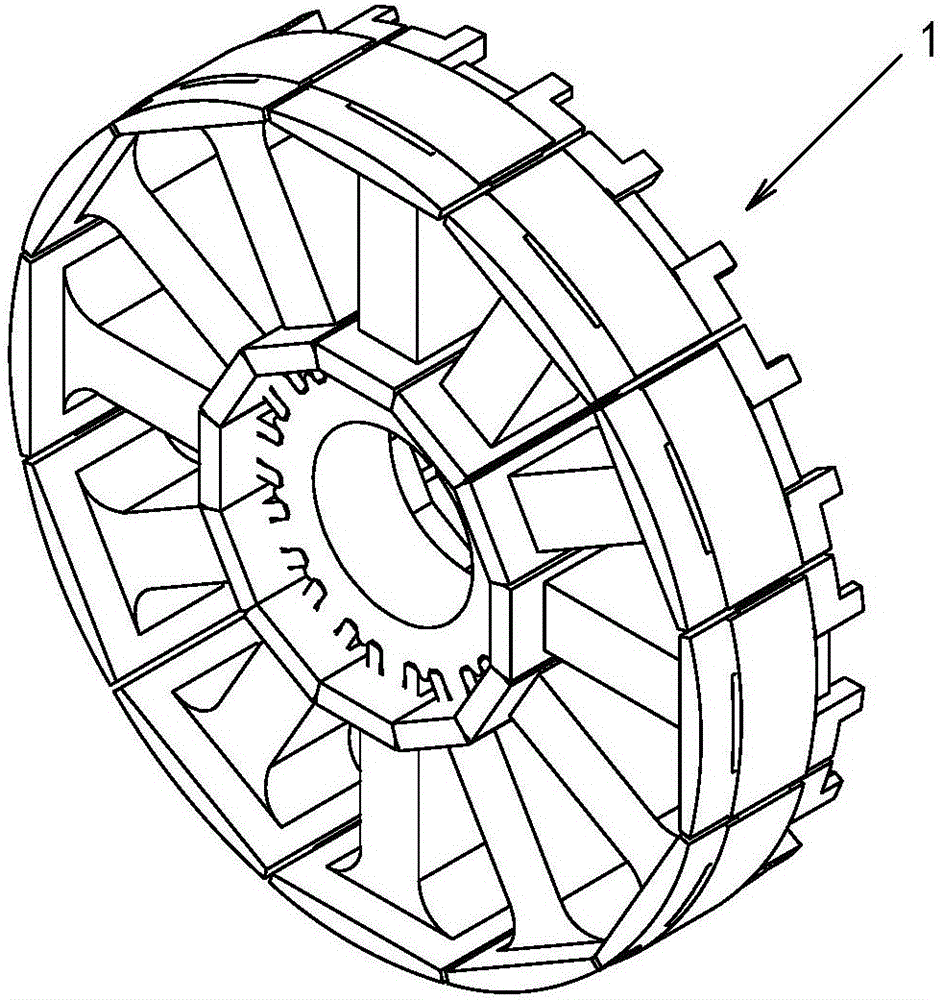

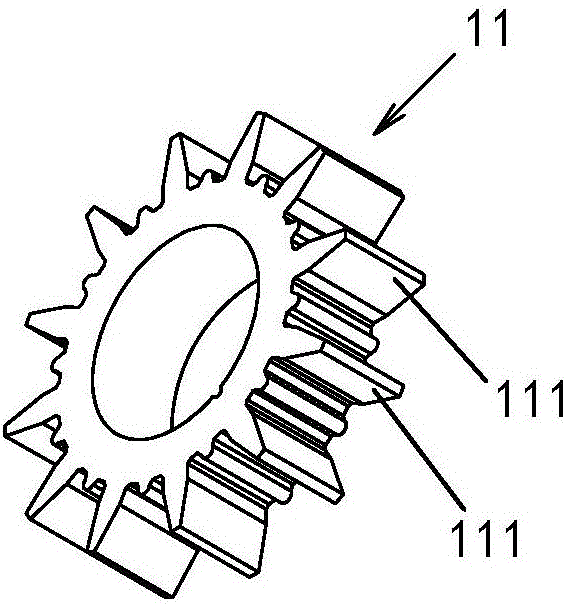

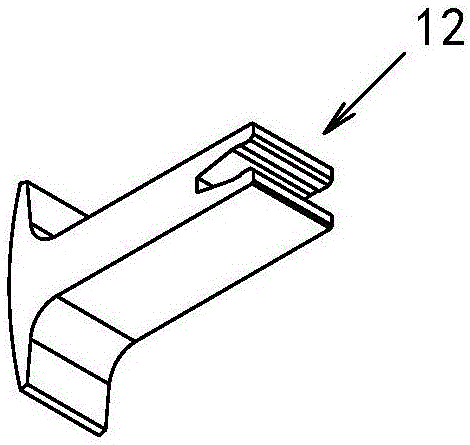

[0031] Example: see Figure 5-15 As shown, a T-shaped iron core pressing device of a motor coil assembly machine:

[0032] see Figure 5 As shown, the motor coil assembly machine includes a frame 2, an annular conveying line 3 is arranged on the frame 2, and a sun-shaped iron core feeding and finished product unloading station 31, a coil unwinding station 31 are successively arranged on the annular conveying line 3 32 and the T-shaped iron core are pressed into the station 3. Conveyor line 3 can adopt double-speed chain.

[0033] see Figure 5 As shown, a plurality of jigs 34 are slidably arranged on the circular conveying line 3 .

[0034] The specific fixture structure is as Figure 6 As shown, the jig 34 includes a workpiece positioning plate 341. The surface of the workpiece positioning plate 341 is provided with a positioning groove for placing products, and the center of the workpiece positioning plate is vertically provided with a central positioning plate for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com