High-pressure grinding material air jet grinding material flow control device and control method thereof

A flow control device and gas jet technology, which is applied in the direction of abrasive feeding device, used abrasive processing device, abrasive, etc., can solve the problem of continuous and stable feeding, uncontrollable abrasive flow, and unsmooth feeding To achieve the effect of convenient and feasible working method, controllable abrasive flow rate and continuous supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

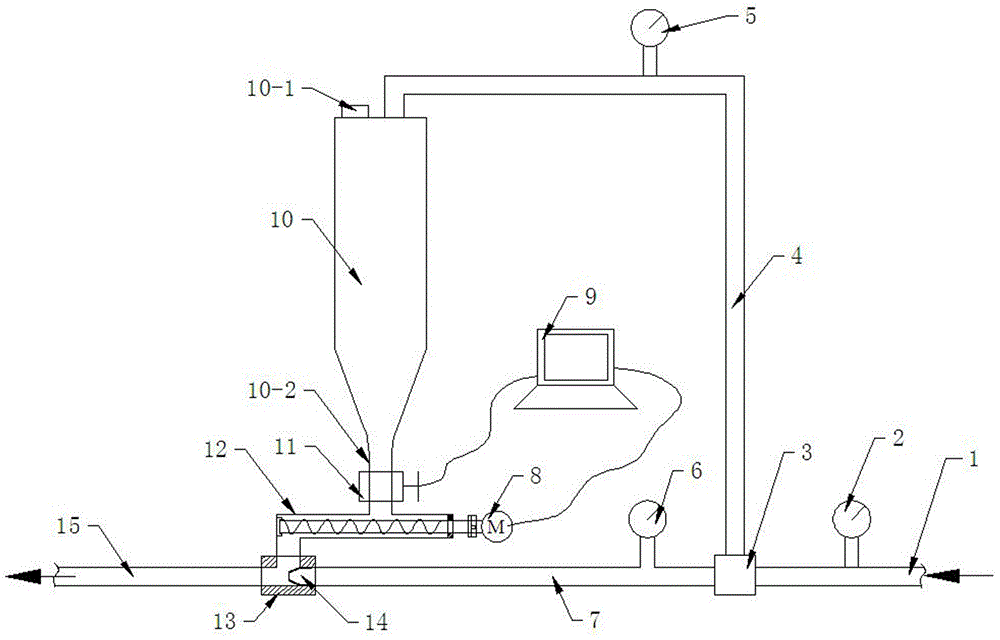

[0021] Embodiment one, such as figure 1 , a high-pressure abrasive gas jet abrasive flow control device, comprising an air inlet pipe 1 and an abrasive tank 10, the right end of the air inlet pipe 1 is connected to a high-pressure air source, and the air inlet pipe 1 is connected to a pressure gauge 2 close to the high-pressure air source and The high-pressure control valve 6 located at the left end of the intake pipe 1, the left side of the high-pressure control valve 6 is connected with the high-pressure air pipe 7 whose left end is the injection nozzle 14, and the outer surface of the injection nozzle 14 is provided with threads and connected to the jet tee The right port of 13 is screwed, and the abrasive pot 10 is a hollow structure with a cylindrical upper end and a conical lower end. The upper end of the abrasive pot 10 is sealed and provided with a feeding port 10-1 connected to the atmosphere. The lower end of 10 is a feed opening 10-2 that is sealed and connected wit...

Embodiment 2

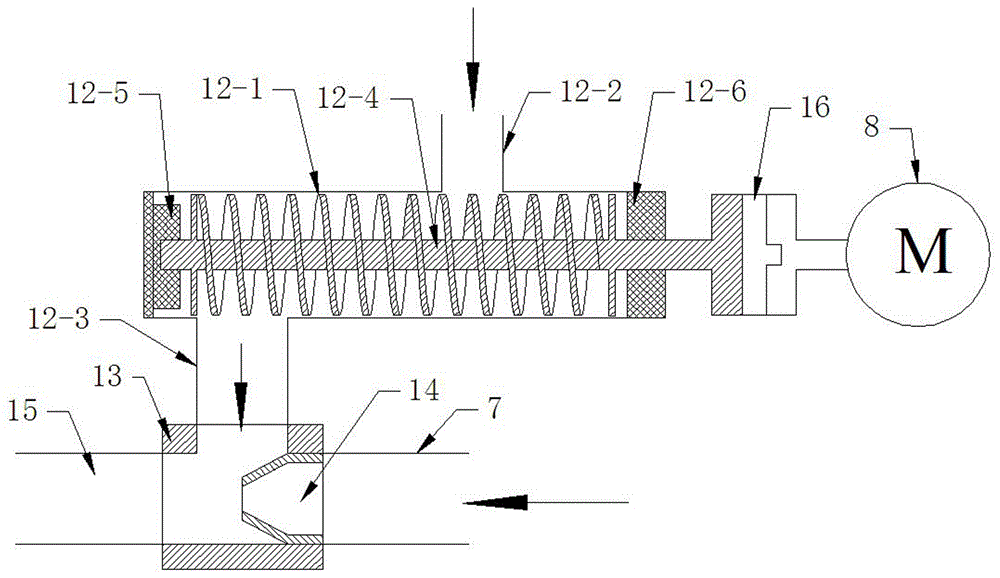

[0022] Embodiment two, such as Figure 1-2 , is basically the same as the first embodiment, the difference is that the screw conveying device 12 includes a conveying cylinder 12-1 and a screw 12-4 located in the conveying cylinder 12-1, and the conveying cylinder 12-1 is provided with a A square abrasive inlet 12-2 and an abrasive outlet 12-3 located at the lower left, the inside of the delivery cylinder 12-1 is provided with a support 12-5 located at the left end and a gasket 12-6 located at the right end, the screw The left end of 12-4 is hinged on the support 12-5, and the right end of the screw rod 12-4 passes through the sealing gasket 12-6 and the right wall of the delivery cylinder 12-1 and is connected with the drive motor 8 through the coupling 16, The abrasive inlet 12 - 2 is in sealing connection with the lower end of the abrasive tank 10 , and the abrasive outlet 12 - 3 is in sealing connection with the upper port of the jet tee 13 .

Embodiment 3

[0023] Embodiment three, such as Figure 1-2 , which is basically the same as Embodiment 1 or Embodiment 2, except that the inlet pipe 1 is connected with a diverter tee 3 between the pressure gauge 2 and the high-pressure control valve 6, and the left port of the diverter tee 3 and the right port are all sealed with the intake pipe 1, the upper port of the split tee 3 is sealed with one end of the balance air pipe 4, the middle of the balance air pipe 4 is connected with a low pressure control valve 5, and the other end of the balance air pipe 4 One end is sealingly connected with the upper end of the abrasive pot 10, and the opening of the feeding port 10-1 is sealed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com