Automatic auxiliary material distributing and warehousing logistics system with ingredient conveyor line

A logistics system and conveying line technology, applied in the field of auxiliary material automatic distribution and storage logistics system, auxiliary material logistics system, can solve the problems of easy error in distribution, disordered on-site management, high labor intensity, etc., to improve the efficiency of storage and storage. , the effect of improving the level of automation and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

[0048] The equipment not specifically pointed out in the present invention is conventional equipment.

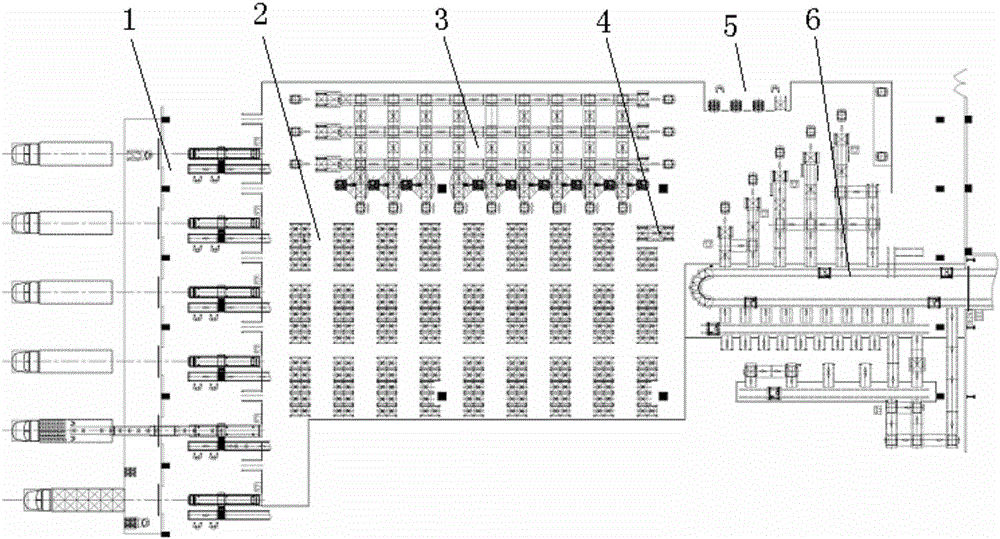

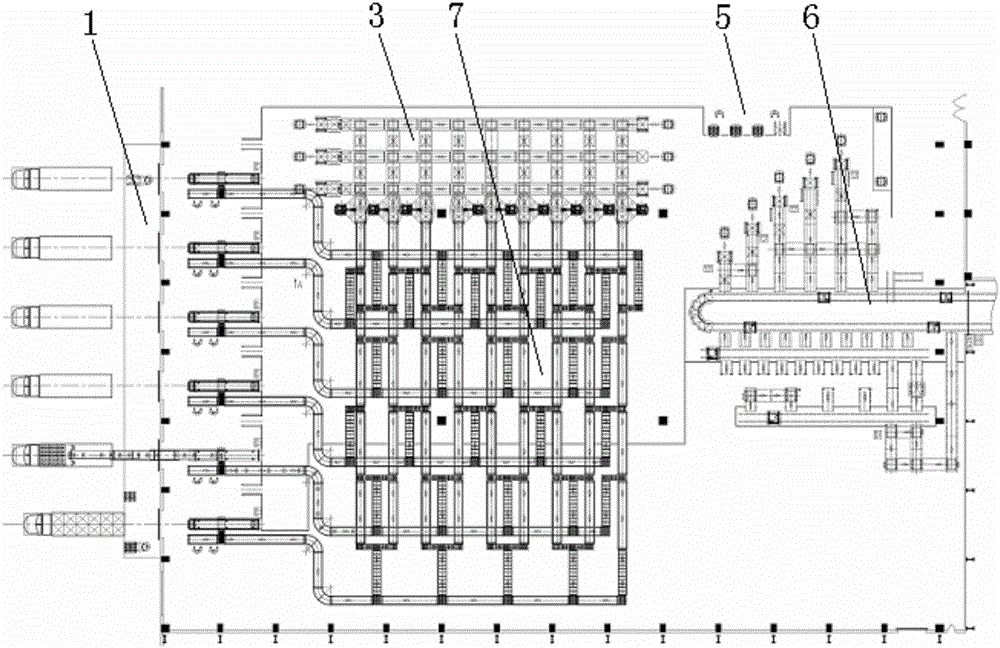

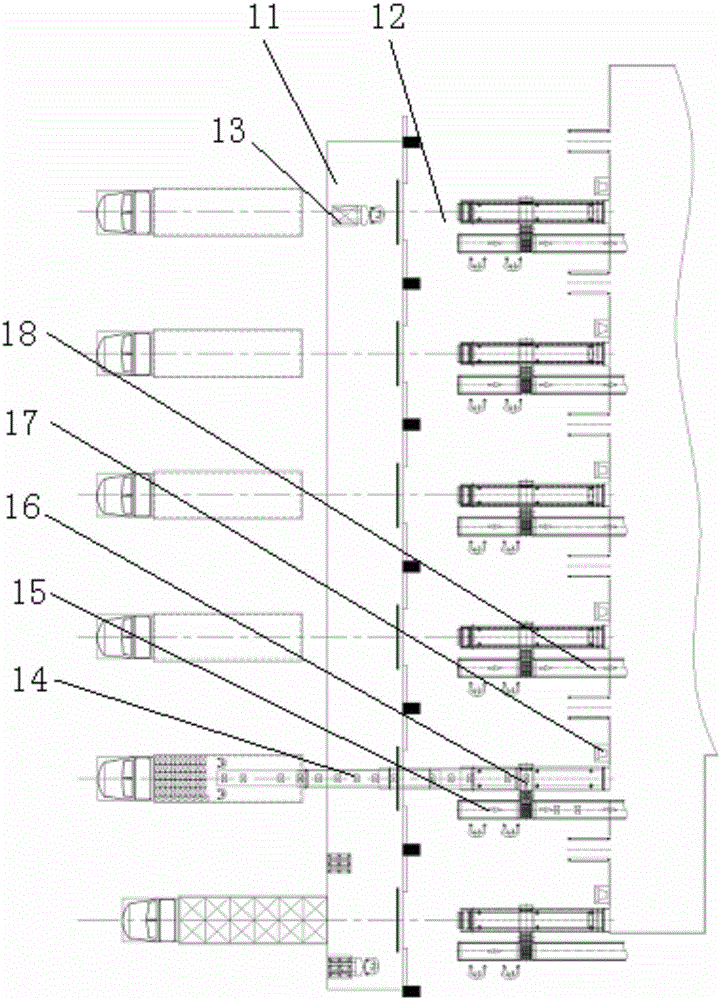

[0049] The auxiliary material automatic distribution and warehousing logistics system of the formula conveying line provided by the present invention includes an unloading and unpacking conveying line 1, a temporary storage warehouse 2, a sorting conveying line 7, a formula conveying line 3, an inspection formula line 5, and a warehousing conveying line 6 , pallet assembly line 4, wherein: the output end of the unloading and unpacking conveying line 1 is connected to the input end of the classification conveying line 7, and at the same time the output end of the unloading and unpacking conveying line 1 is also connected to the entrance of the temporary storage warehouse 2, and the classification conveying line 7 is located at Above the temporary storage 2, the formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com