Feeding rotating assembly for piston rod feeding mechanism

A technology of rotating components and piston rods, used in conveyor objects, conveyors, transportation and packaging, etc., can solve problems such as low work efficiency, increased production cost, complex structure, etc., to achieve high work efficiency, convenient operation, and reduced production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

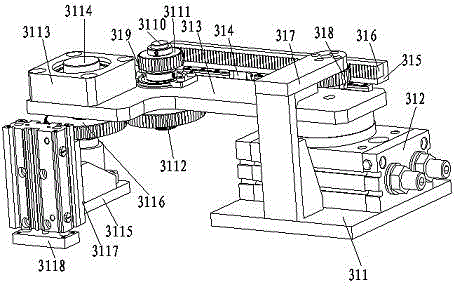

Image

Examples

Embodiment Construction

[0007] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0008] see figure 1 , the embodiment of the present invention includes:

[0009] A feeding rotary assembly of a piston rod feeding mechanism, the feeding rotating assembly 31 of the piston rod feeding mechanism includes a piston rod feeding mounting plate 311, and a piston rod feeding mounting plate 311 is fixed on the upper end surface of the piston rod feeding mounting plate 311. Rotary cylinder 312, on the rotary table of piston rod feeding rotary cylinder 312, rotary plate 313 is fixed, and the upper end surface of rotary plate 313 is fixed with rotary guide rail 314, and the slide block of rotary guide rail 314 is fixed with rotary displacement plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com