Unpowered full-automatic loading machine for bagged cement

A car loader, fully automatic technology, applied in the direction of conveyor, loading/unloading, conveyor objects, etc., can solve the problems of easy failure, high mechanical reliability requirements, poor environment, etc., to speed up the loading speed, The effect of saving human and financial resources and enhancing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

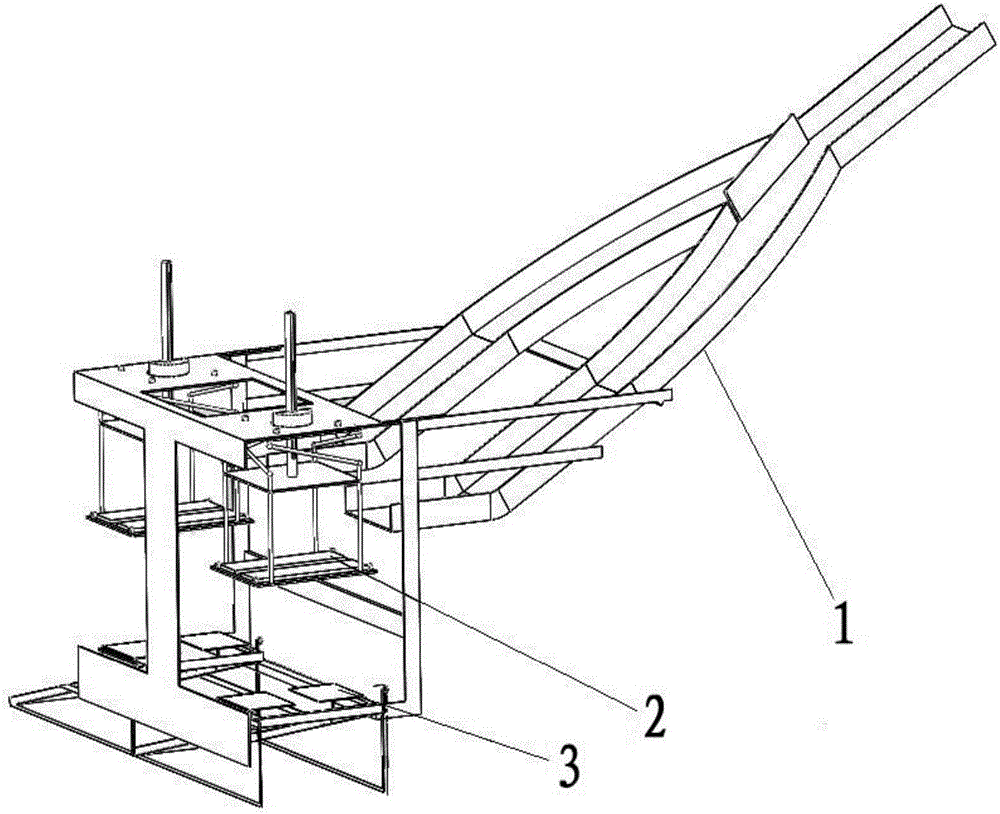

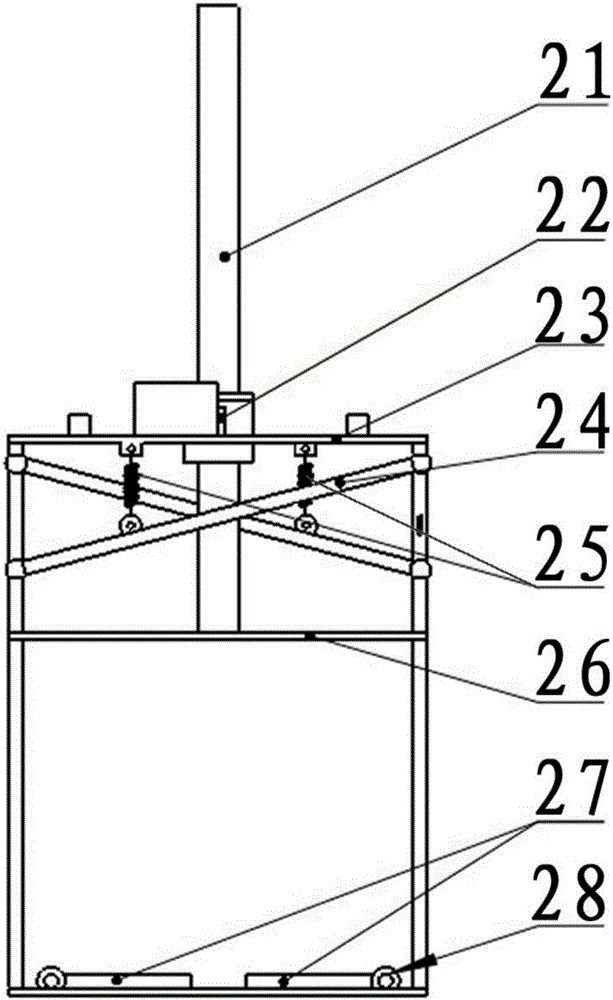

[0026] The invention provides a kind of unpowered automatic loading machine of bagged cement (referring to Figure 1-6 , referred to as the loading machine), including a diversion mechanism 1, a reversing mechanism 2 and a positioning stacking mechanism 3; 3 is placed vertically below the reversing mechanism 2;

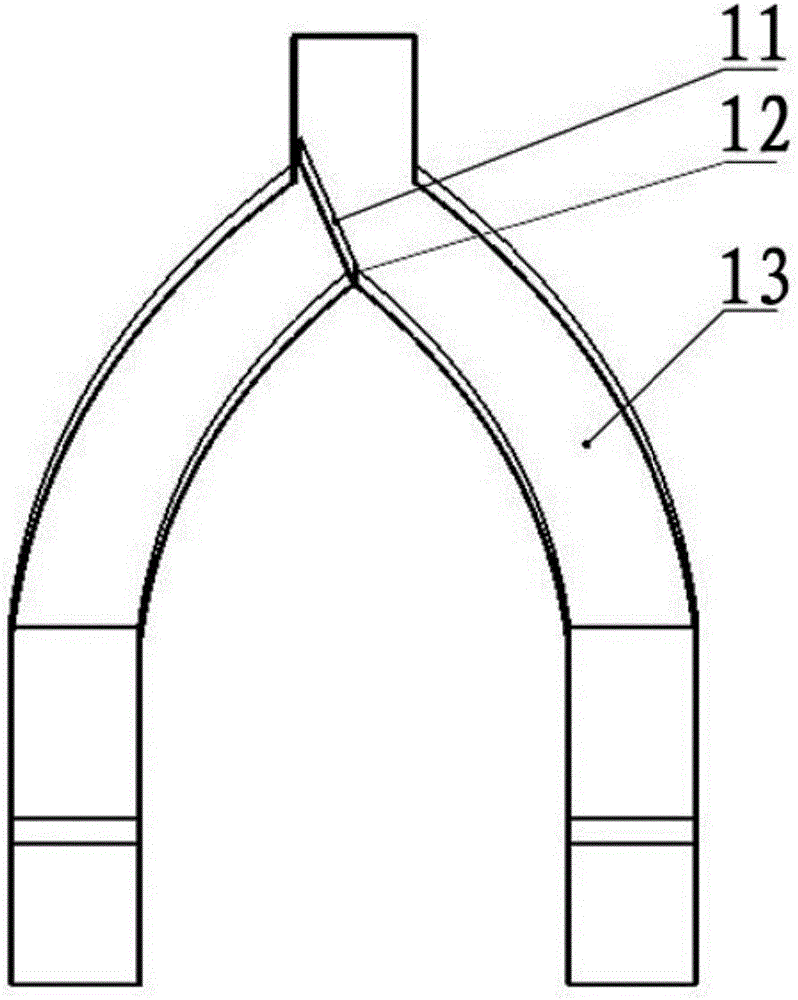

[0027] The distribution mechanism 1 includes a distribution paddle 11, a paddle shaft 12 and a cement distribution channel 13; the cement distribution channel 13 has an inlet, a left channel and a right channel; the cement distribution channel 13 is fixed on the vehicle loading frame body The shunt paddle 11 is installed on the cement shunt channel 13 through the paddle shaft 12, the shunt paddle 11 can rotate around the shaft 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com