Lithium-type low-silica faujasite, its preparation method and use

A faujasite and medium-silicon octahedral technology, which is applied in the field of lithium-type low-silicon faujasite, can solve the problems of reduced mechanical strength of shaped particles, reduced adsorption performance, and slow crystallization speed, achieving excellent adsorption performance and easy operation , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] A preparation method of lithium-type low-silicon faujasite, comprising the following steps:

[0015] (1) SiO 2 / Al 2 o 3 The shaped particles of medium silica faujasite with a molar ratio of 2.2 to 3.0 are uniformly mixed with a caustic solution comprising sodium hydroxide and potassium hydroxide to prepare a reaction mixture;

[0016] (2) carrying out the hydrothermal reaction to the reaction mixture in the step (1), to obtain a shaped low-silicon faujasite solid product;

[0017] (3) Exchanging the solid product obtained in step (2) with lithium to obtain shaped lithium-type low-silicon faujasite.

[0018] Each step is described in detail below.

[0019] In step (1) of the method of the present invention, the molar concentration of the caustic solution comprising sodium hydroxide and potassium hydroxide is 1-10mol / L, preferably 3-8mol / L, more preferably 5-7.5mol / L , wherein the K / (Na+K) molar ratio is 0.1-0.5, preferably 0.20-0.4, more preferably 0.25-0.35.

[0...

Embodiment 1

[0039] 407.6 grams of sodium hydroxide (98.0% purity) and 255.0 grams of potassium hydroxide (85% purity) were successively stirred and dissolved in 1680.7 grams of water. Due to the exothermic solution heat up, after complete dissolution, let the solution cool, then add a small amount of water to compensate for the evaporated water, until the initial concentration. 406.7 g of SiO 2 / Al 2 o 3 Shaped particles of medium silica faujasite with a molar ratio of 2.27 (marked as R1; uncalcined activated binderless 13X spherical shape, 1.6 mm in diameter, Germany CWK, 13XBFK) were added to the above caustic solution.

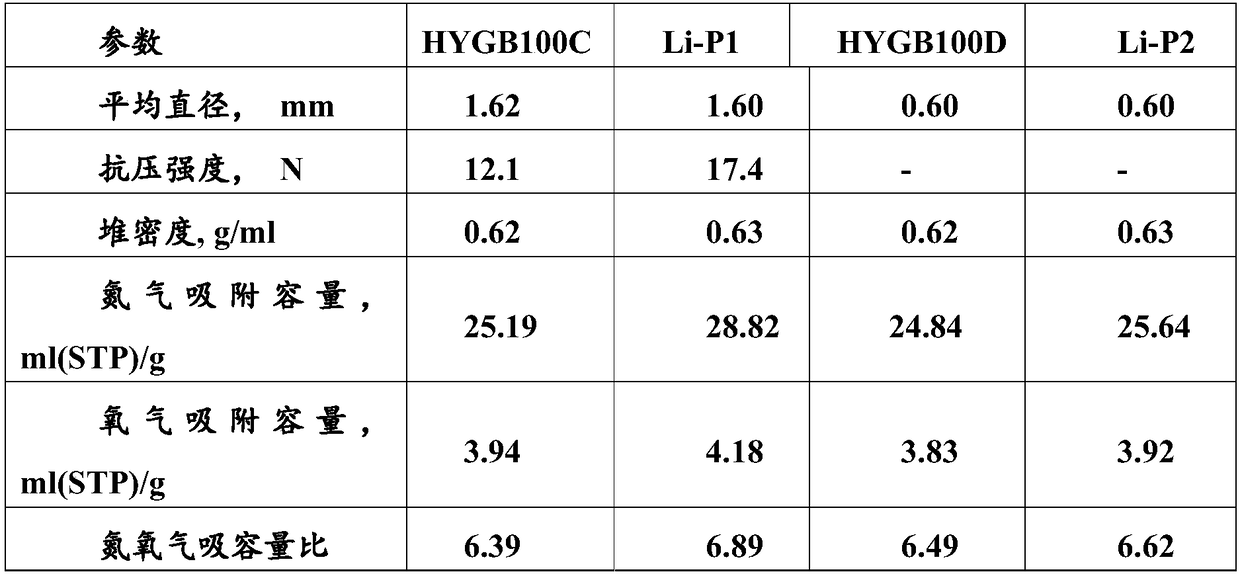

[0040] After stirring the mixture slightly, the mixture was then heated to 77°C under static conditions to carry out the hydrothermal reaction of crystal transformation. After 25 hours of reaction, the reaction was complete. After cooling, the NaKLSX particle product, labeled P1, was recovered through filtration, washing and drying steps. Table 1 shows the changes...

Embodiment 2

[0043] In 1437.8 grams of deionized water, 348.6 grams of sodium hydroxide (98.0% purity) and 221.2 grams of potassium hydroxide (85% purity) were added sequentially and stirred until a completely dissolved liquid was formed. 392.3 g of SiO 2 / Al 2 o 3 Raw materials with a molar ratio of 2.52 (marked as R2; after absorbing moisture, 13X spherical balls with a binder and a diameter of 0.6mm, Luoyang Jianlong, JLOX-501) were added to the prepared solution to obtain a mixture.

[0044] After the mixture was slightly stirred, it was heated to 75° C. under static conditions to carry out the hydrothermal reaction of crystal transformation. After 38 hours of reaction, the reaction was complete and the heating was stopped. After cooling, the NaKLSX particle product, labeled as P2, was recovered through filtration, washing and drying steps.

[0045] Table 1 shows the changes in the silicon-aluminum ratio of the chemical composition before and after the conversion of molecular sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com